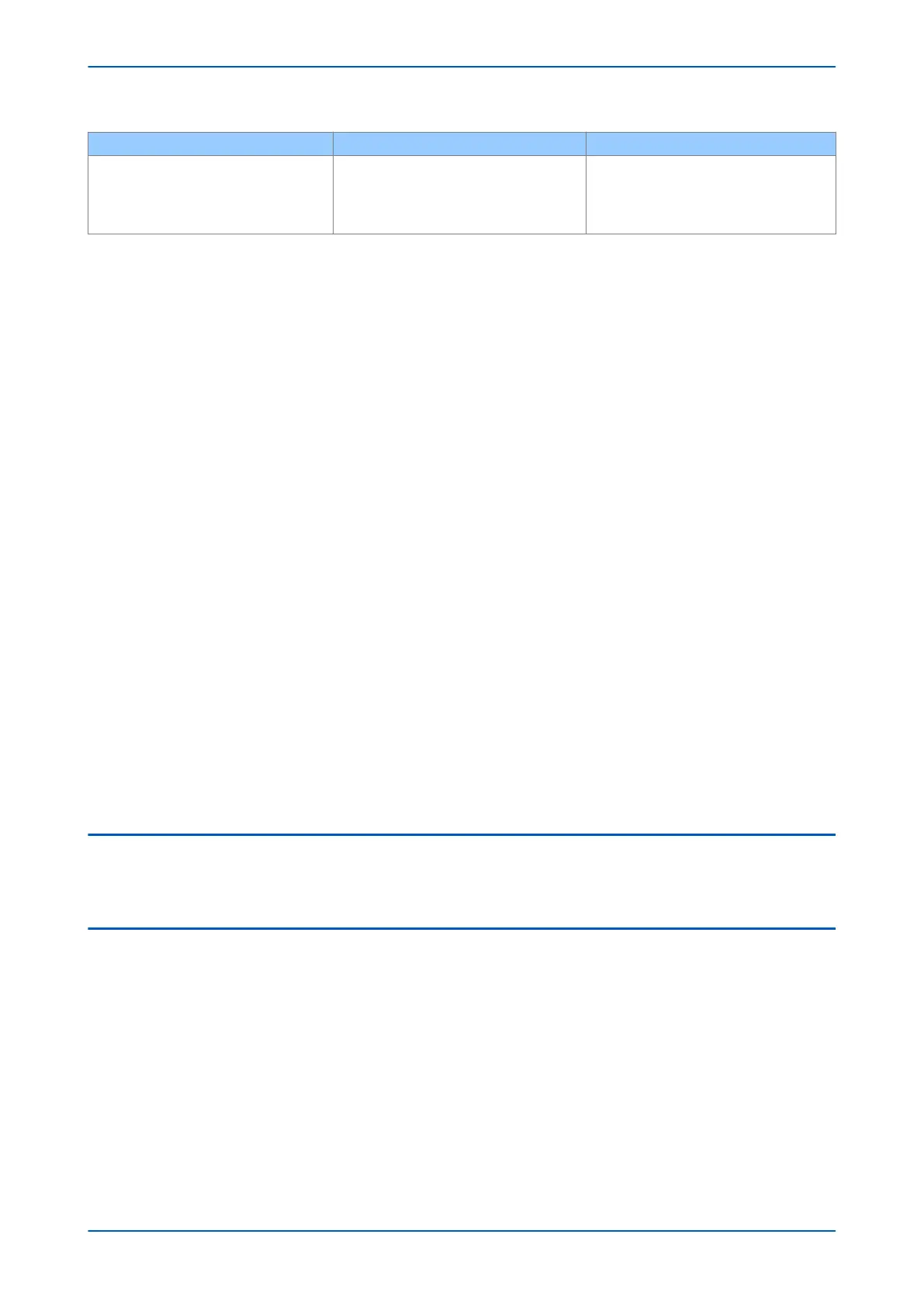

Measurement Mode Parameter Signing

3

Export Power

Impor

t Power

Lagging Vars

Leading VArs

–

+

–

+

The device also calculates the per-phase and three-phase power factors.

These pow

er values increment the total real and total reactive energy measurements. Separate energy

measurements are maintained for the total exported and imported energy. The energy measurements are

incremented up to maximum values of 1000 GWhr or 1000 GVARhr at which point they reset to zero. It is possible

to reset these values using the menu or remote interfaces using the Reset demand cell.

These measurements are contained in the MEASUREMENTS 2 column.

4.1.4 DEMAND VALUES

The device produces fixed, rolling, and peak demand values. You reset these quantities using the R

eset demand

cell.

The fixed demand value is the average value of a quantity over the specified interval. Values are produced for

three phase real and reactive power. The fixed demand values displayed are those for the previous interval. The

values are updated at the end of the fixed demand period according to the Fix Dem Period setting in the

MEASURE'T SETUP column.

The rolling demand values are similar to the fixed demand values, but a sliding window is used. The rolling demand

window consists of a number of smaller sub-periods. The resolution of the sliding window is the sub-period length,

with the displayed values being updated at the end of each of the sub-periods according to the Roll Sub Period

setting in the MEASURE'T SETUP column.

Peak demand values are produced for each phase current and the real and reactive power quantities. These

display the maximum value of the measured quantity since the last reset of the demand values.

These measurements are contained in the MEASUREMENTS 2 column.

4.1.5 OTHER MEASUREMENTS

Depending on the model, the device produces a range of other measurements such as thermal measurements.

These measur

ements are contained in the MEASUREMENTS 3 column.

4.2 MEASUREMENT SETUP

You can define the way measurements are set up and displayed using the ME

ASURE'T SETUP column and the

measurements are shown in the relevant MEASUREMENTS tables.

4.3 OPTO-INPUT TIME STAMPING

Each opto-input sample is time stamped within a tolerance of +/- 1 ms with respect to the Real Time Clock. These

time stamps ar

e used for the opto event logs and for the disturbance recording. The device needs to be

synchronised accurately to an external clock source such as an IRIG-B signal or a master clock signal provided in

the relevant data protocol.

For both the filtered and unfiltered opto-inputs, the time stamp of an opto-input change event is the sampling time

at which the change of state occurred. If multiple opto-inputs change state at the same sampling interval, these

state changes are reported as a single event.

P64x Chapter 13 - Monitoring and Control

P64x-TM-EN-1.3 275

Loading...

Loading...