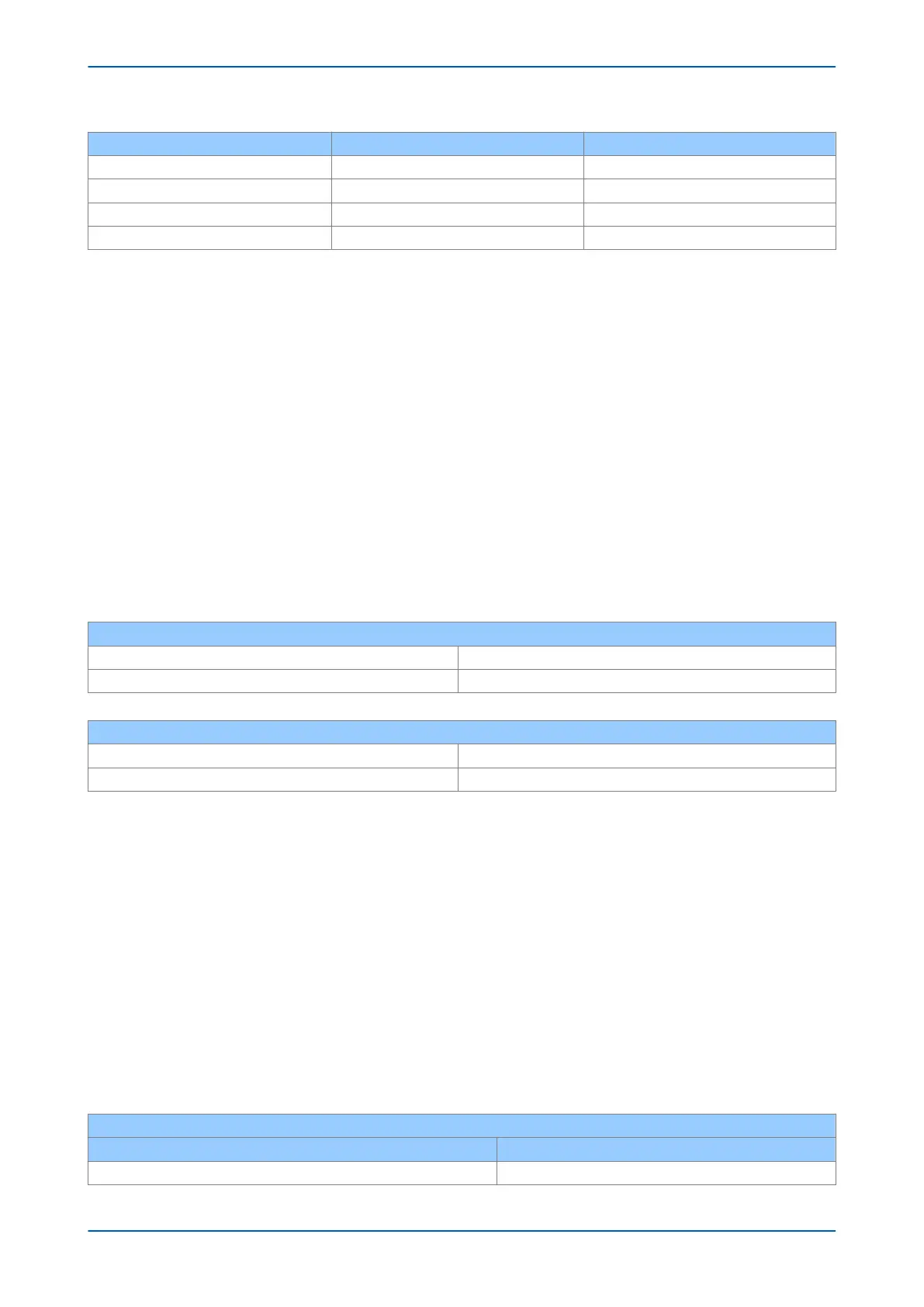

Type of cooling m (winding exponent) n ( oil exponent)

OA 0.8 0.8

FA 0.8 0.9

Non-directed FOA or FOW 0.8 0.9

Directed FOA or FOW 1.0 1.0

The cooling mechanisms are:

● O

A (Oil/Air): The cooling system transfers heat using oil or air without using pumps or fans.

● FA (Forced Air): The cooling is aided by fans, without any pumps to circulate the oil.

● FOA (Forced Oil and Air): The cooling system uses both pumps and fans to cool the winding.

● FOW (Forced Oil and Water): The heat exchanger is water-cooled and does not have the typical radiator

configuration. The cooler is normally a chamber with many tubes inside where the oil and water exchange

heat energy. In non-directed flow transformers, the pumped oil flows freely through the tank. In directed

flow transformers, the pumped oil is forced to flow through the windings.

The exponents are empirically derived and are required to calculate the variation of DQH and DQTO with load

changes. The value of m has been selected for each mode of cooling to approximately account for effects of

changes in resistance and viscosity with changes in load. The value of n has been selected for each mode of

cooling to approximately account for effects of change in resistance with change in load.

Oil Time Constant

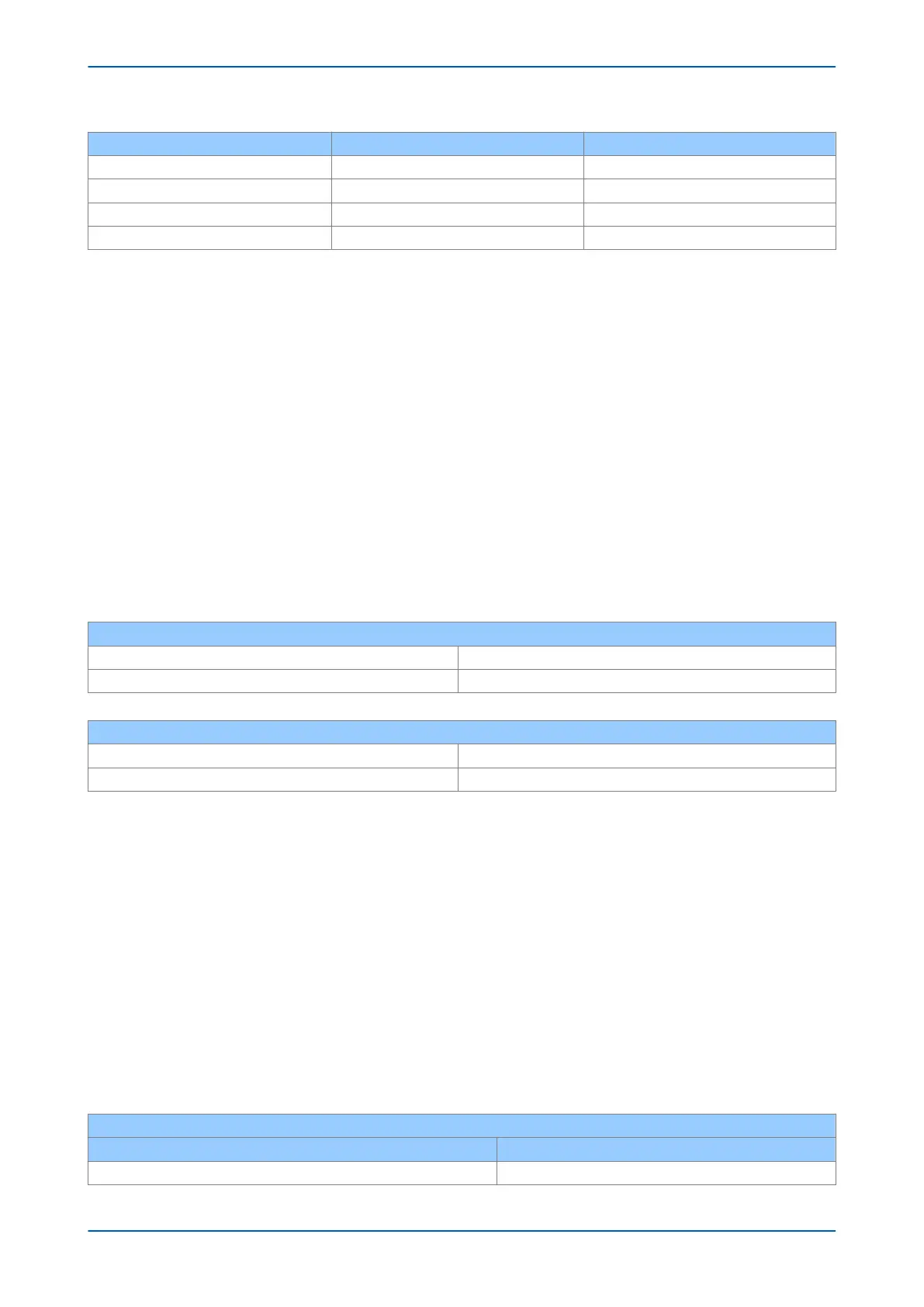

When setting the Hotspot and Top Oil stages take into consideration the suggested temperature limits (IEEE Std.

C57.91-1995):

Suggested limits of temperature for loading above nameplate distribution transformers with 65° C rise

Top Oil temperature 120°C

Hotspot conductor temperature 200°C

Suggested limits of temperature for loading above nameplate power transformers with 65° C rise

Top Oil temperature 110°C

Hotspot conductor temperature 180°C

2.3.3 DATA PROVIDED BY TRANSFORMER MANUFACTURERS

The transformer manufacturer should provide information pertaining to the following parameters:

Rat

ed NoLoadLoss: The ratio of load loss at rated load to no load loss.

Hot Spot Overtop: Winding hottest-spot rise over Top Oil at rated load

Top Oil overamb: Top Oil rise over ambient temperature at rated load

Winding exp m: Winding exponent

Oil exp n: Oil exponent

HotSpotRiseConst: Winding time constant at Hotspot location (this may also be estimated from the resistance

cooling curve during thermal tests)

TopOilRiseConst (Oil time constant)

The following tables are examples of the thermal data provided by the transformer manufacturer:

Thermal characteristics for a 735 MVA 300 kV +7% to -18% / 23 kV ODWF cooled generator transformer

Specification Value

No load losses (core losses) 340 kW

Chapter 7 - Transformer Condition Monitoring P64x

148 P64x-TM-EN-1.3

Loading...

Loading...