5 RTD PROTECTION

Prolonged overloading of transformers may cause their windings to overheat, resulting in premature aging of the

insulation, or in extr

eme cases, insulation failure. To protect against this, resistive temperature sensing devices

(RTDs) can be used to measure temperatures at various locations within a transformer. RTDs work by using the

resistance versus temperature characteristic of metals. When metal heats up, its resistance changes. This can be

used to feed back temperature information, which can be used by protection devices for temperature monitoring,

alarming, or making protection decisions.

Probes are usually placed in areas of the equipment that are susceptible to overheating or heat damage. This

could protect against winding Hotspot overheating or overtemperature in the insulating oil.

Direct temperature measurement can provide more reliable thermal protection than thermal model calculations.

Note:

Do Not select RTD options if RTD board is not fitted.

5.1 RTD PROTECTION IMPLEMENTATION

The P64x uses PT100 RTD probes to protect against any general or localized overheating. These can measure

temperatur

es between –40° and +300°C. At 0°C they have a resistance of 100 Ohms.

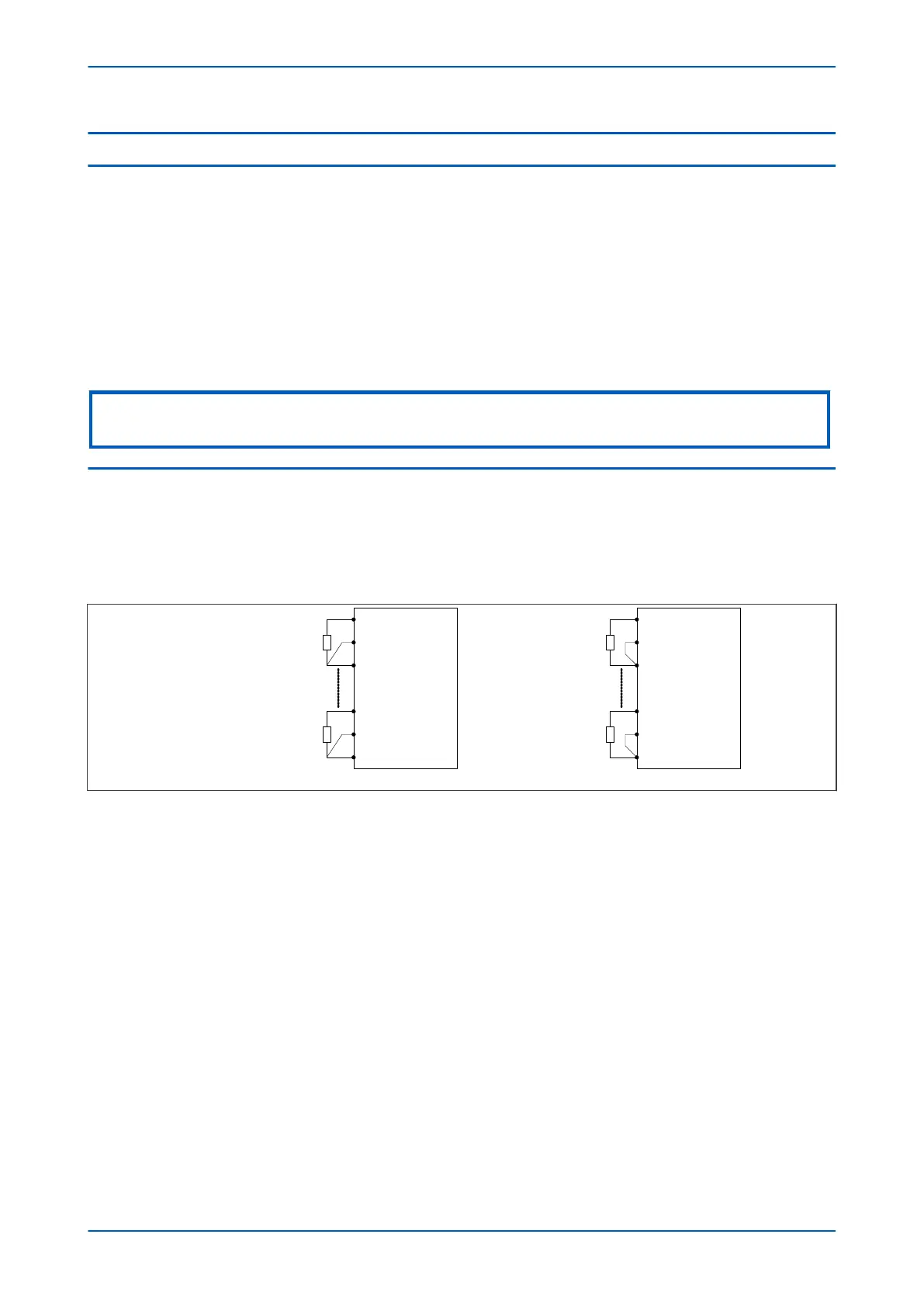

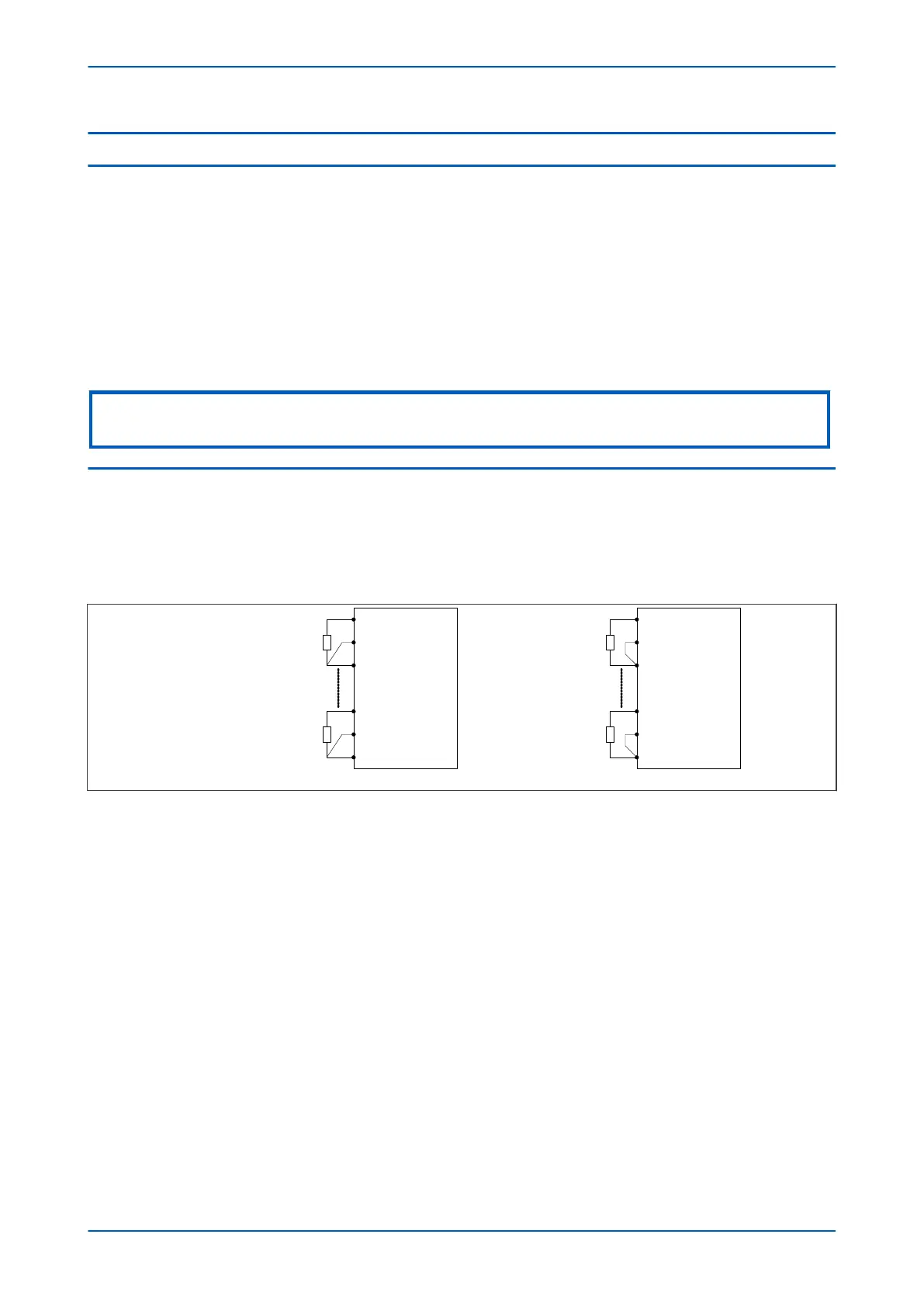

The device accepts inputs from up to ten 2-wire or 3-wire PT100 resistive temperature sensing devices (RTD). These

are connected as shown:

V03202

IED

RTD 1

RTD 10

3-wire PT100 RTDs

IED

2-wire PT100 RTDs

RTD 1

RTD 10

Figure 65: Connection for RTD thermal probes

You can enable or disable each RTD using the Select RTD setting in the RTD PROTECTION column of the relevant

settings group. The setting contains a binary string of ten digits to represent the 10 RTDs in sequence from right to

left. For example if you set Select RTD to 0000000111, RTD1, RTD2 and RTD3 would be enabled and the associated

settings would be visible in the menu.

You set the temperature setting for the alarm stage for each RTD in the RTD Alarm Set cells and the alarm stage

time delay in the RTD Alarm Dly cells.

Likewise, you set the trip stage for each RTD in the RTD Trip Set cells and the trip stage time delay in the RTD Trip

Dly cells.

Should the measured resistance of an RTD be outside of the permitted range, an RTD failure alarm is raised,

indicating an open or short circuit RTD input. These conditions are signalled by the DDB signals RTD Open Cct, RTD

Short Cct and RTD Data Error. These DDB statuses are also shown in the MEASUREMENTS 3 column.

DDB signals are also available to indicate the alarm and trip of the each and any RTD. You can set the monitor bit

cells in the COMMISSION TESTS column to view the statuses of these signals.

P64x Chapter 7 - Transformer Condition Monitoring

P64x-TM-EN-1.3 157

Loading...

Loading...