Loading...

Loading...

Do you have a question about the INVT Goodrive270 Series and is the answer not in the manual?

| Control Mode | V/F control, Sensorless vector control |

|---|---|

| IP Rating | IP20 |

| Cooling Method | Air cooling |

| Overload Capacity | 150% for 60 seconds |

| Protection Functions | Overcurrent, Overvoltage, Undervoltage, Overheat, Overload, Short circuit |

| Communication | RS485, Modbus |

| Application | Water pump |

| Input Frequency | 50Hz/60Hz |

| Output Voltage | 0~Rated Voltage |

| Rated Current | Depends on the model |

| Operating Temperature | -10°C to +40°C |

| Storage Temperature | -20°C to 60°C |

| Humidity | <95% (non-condensing) |

| Altitude | Below 1000m |

Defines safety terms (Danger, Warning, Note) and lists warning symbols.

Covers essential precautions for handling, installation, operation, and maintenance.

Details unpacking, pre-use checks, and environmental requirements for VFD installation.

Outlines fundamental steps for initial VFD setup, motor parameter configuration, and autotuning.

Explains the VFD's basic principles, technical specifications, and features.

Details the VFD model designation code and product ratings for various power outputs.

Illustrates the physical structure and identifies the main components of the VFD.

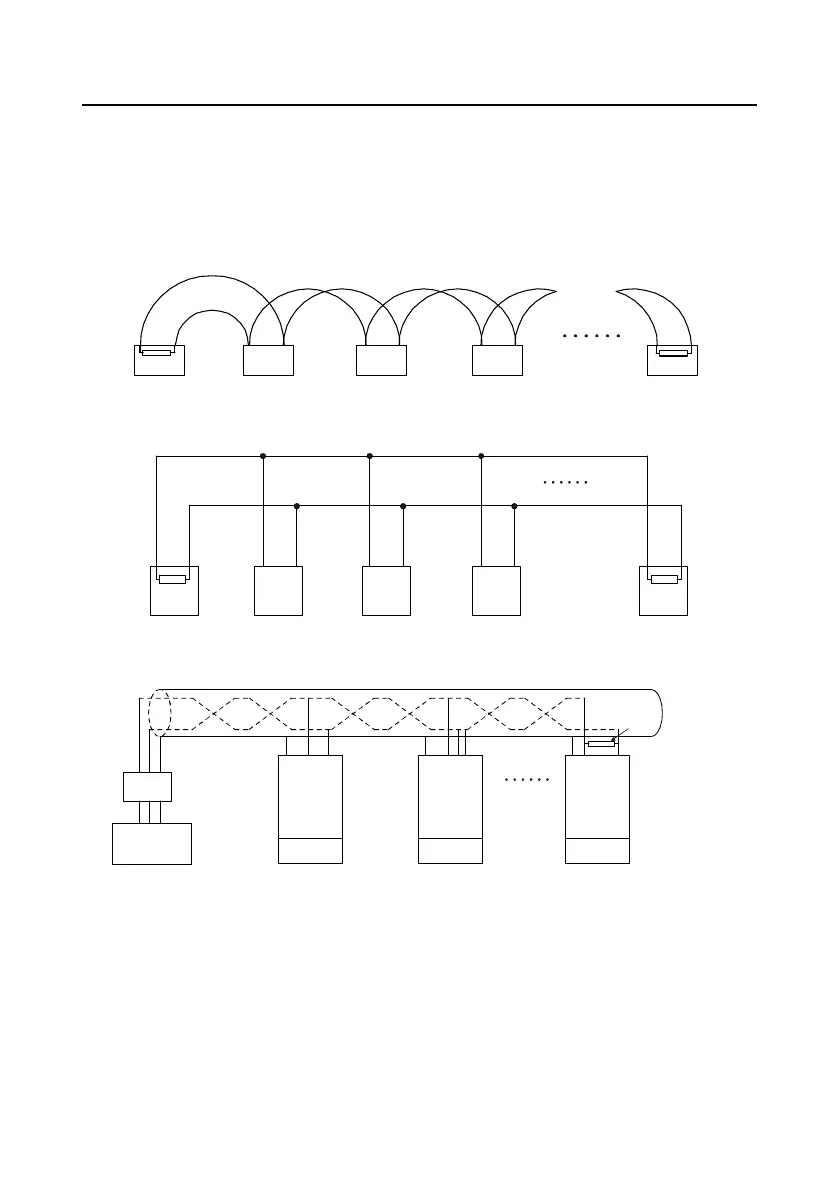

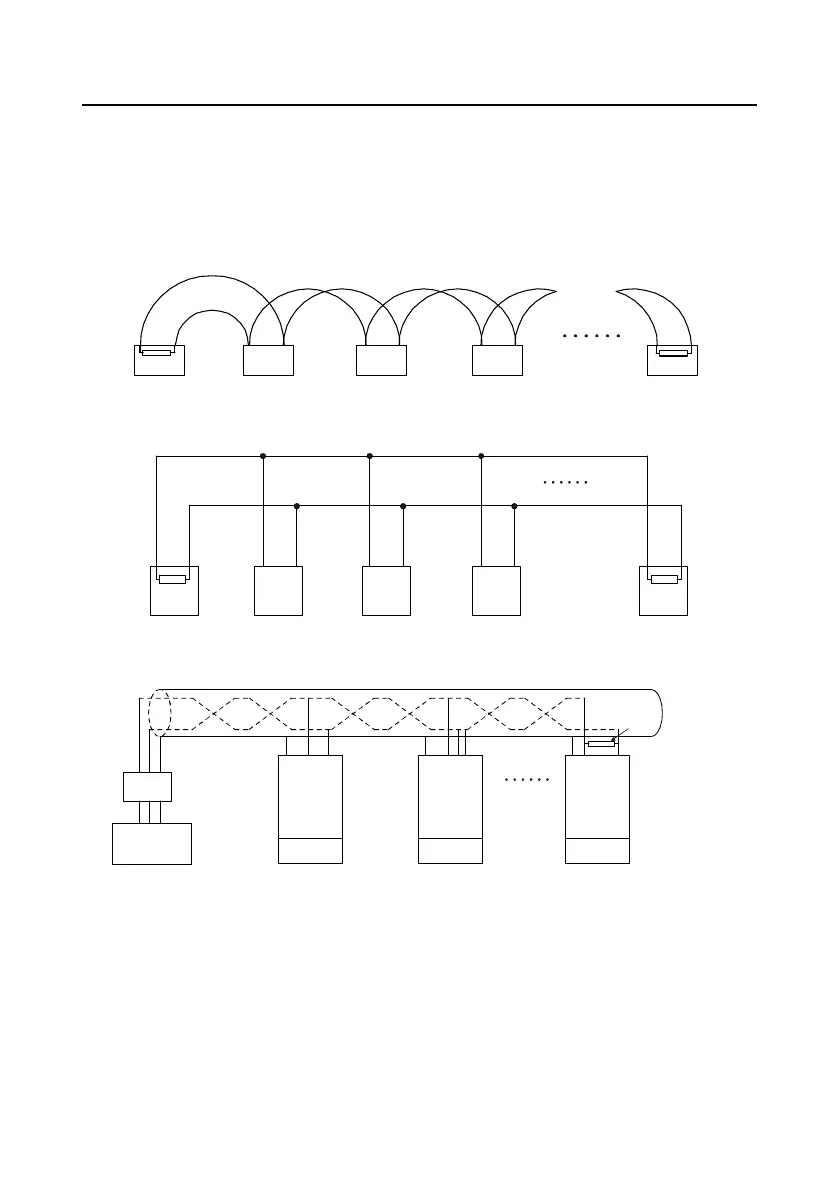

Covers environment, direction, mounting methods, clearances, and cabinet installation.

Details main circuit, control circuit, external keypad, and wiring protection procedures.

Explains LED and LCD keypad functions, parameter display, and editing.

Covers parameter configuration, autotuning, control modes (Vector, Space Voltage), and frequency settings.

Details Simple PLC, PID control, water pump control, and protection features.

Covers basic functions, motor 1 parameters, vector control, and V/F control for motor 1.

Details V/F control for motor 2, input/output terminals, human-machine interface, enhanced functions, PID, and protection.

Covers Simple PLC, motor 2 parameters, communication, status, HVAC, water pump, and protection functions.

Explains how faults are indicated and how to reset them.

Lists common faults, their causes, and solutions for troubleshooting.

Addresses interference issues with sensors, RS485, motor cables, and RCDs.

Outlines routine checks for VFD components and procedures for cooling fan replacement.

Describes capacitor reforming, replacement, and power cable inspection.

Details Modbus protocol, RTU frame structure, error checks, and command examples.

Explains wiring and functions for PROFIBUS, CAN, and PROFINET expansion cards.

Covers derating conditions, technical specifications, EMC requirements, and application standards.

Provides detailed dimensions for keypads, VFDs, and mounting brackets.

Details selection guidelines for filters, reactors, and power/control cables.

Covers selection of breakers, contactors, and other optional accessories.

Contact information for product queries, service, and manual feedback.