Power Module Installation

1. Inspect the main frame guide rails. Remove any

debris which would interfere with power module

installation.

2. Clean the main frame rear support brackets. Apply

a light film of soap solution to each rubber bushing

(3, Figure 2-5) located at the rear of the subframe.

3. Check the subframe rollers making sure they roll

freely and are in the “roll–out” position. ( Figure

2-6).

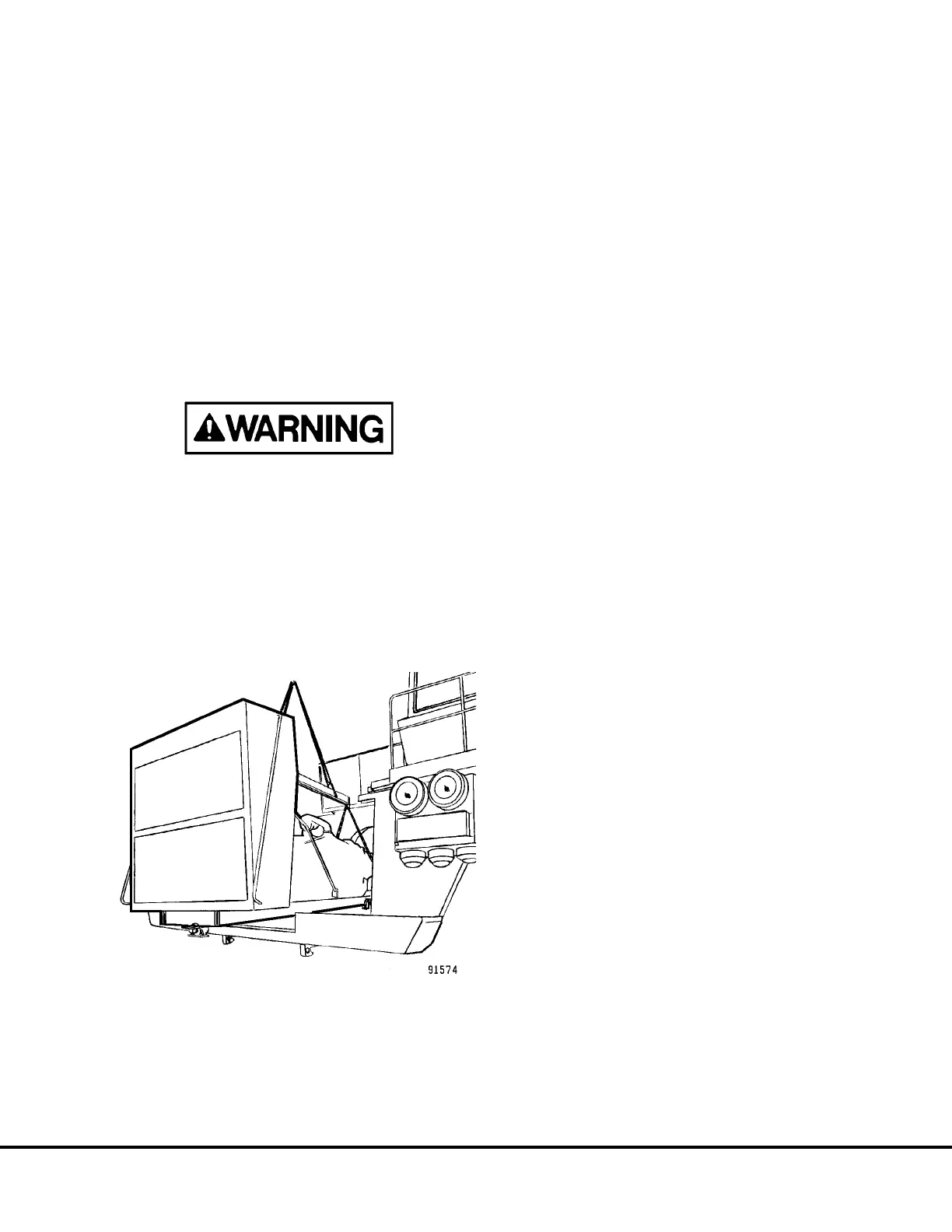

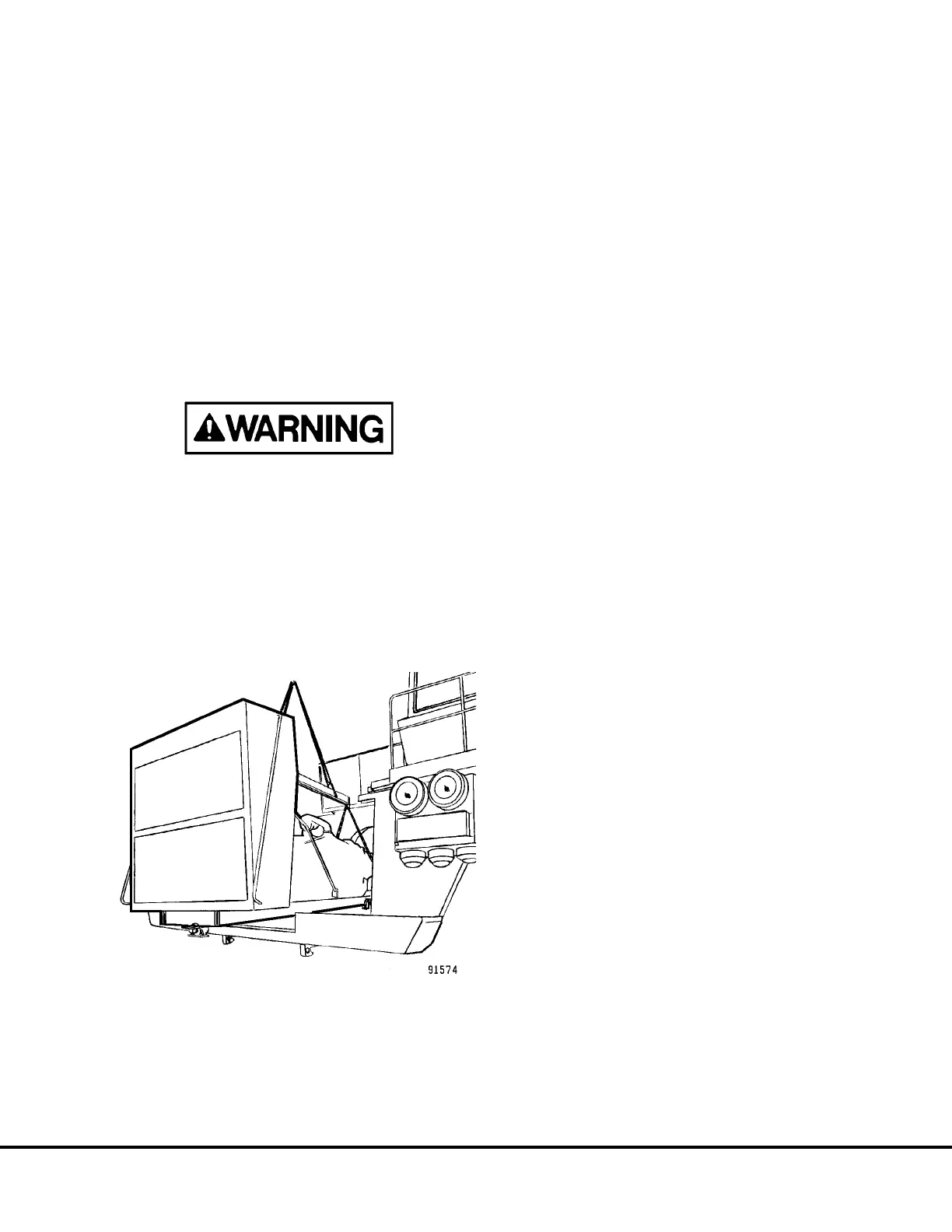

4. Attach a lifting device to engine/alternator cradle

structure and front subframe lifting points (Figure

2-7).

The complete power module, including the hood

and grille weighs approximately 34,750 lbs. (15,760

kg). Make sure lifting device to be used has ade-

quate capacity.

5. Raise the power module and align the subframe

rollers within the main frame guide rails.

6. Lower the power module to the subframe guide

rails, relax the hoist slightly and roll the power

module into truck frame as far as possible before

the lifting chains contact the electrical cabinet.

7. Place stands or blocking under front of subframe

to support assembly while repositioning hoist.

8. Install a safety chain around the truck frame and

the subframe. The safety chain will prevent the

power unit from rolling forward.

9. Place a small block behind each rear subframe

roller to prevent rolling.

10. Lower hoist to allow subframe to rest on stands

and rollers. Remove lifting device.

11. Attach hoist to front lifting eyes on subframe.

12. Remove the small blocks behind the subframe

rollers, remove safety chain, and slowly roll the

power module into position over the main frame

mounts. Lower hoist until front subframe mounts

are aligned and seated on the front, main frame

mounts. Reinstall safety chain.

13. Place a jack under rear of subframe to support the

power module. Raise power module just enough

to permit removing the subframe rollers.

14. Lower the rear portion of the subframe until the

subframe rubber bushings are seated in the

mounting brackets (3, Figure 2-5) located on the

main frame of the truck.

15. After subframe is seated in frame mounts, the

safety chain may be removed from the front sub-

frame member.

16. Install rubber bushings, capscrews, washers and

nuts in the front mounts (8, Figure 2-5). Tighten

capscrews to 525 ft. lbs. (712 N.m) torque.

17. Install the rear subframe mounting caps and se-

cure caps in place with lubricated capscrews.

Tighten capscrews to 407 ft. lbs. (551 N.m)

torque. (Refer to Figure 2-5).

Power Module Hookup

1. Install all ground straps between frame and sub-

frame. Reconnect wire harnesses at power mod-

ule subframe connectors.

2. Install vertical and diagonal ladders on mounting

pads at front bumper.

FIGURE 2-8. POWER MODULE INSTALLATION

C02017 03/01 Power Module C2-7

Loading...

Loading...