6. Install clamps (17) on cover rings (9). Tighten

clamps just enough to hold covers in place.

7. Charge front suspension as described in “Oiling

and Charging Procedure”, Section “H”.

8. Charge rear suspensions with nitrogen to fully

extend pistons.

9. Remove blocks or stands from beneath the frame.

10. Release nitrogen from rear suspension and

charge according to procedure in “Oiling and

Charging Procedure”, Section “H”.

Before removing blocks from the wheels, make

sure parking brake is applied.

11. Remove blocks from wheels.

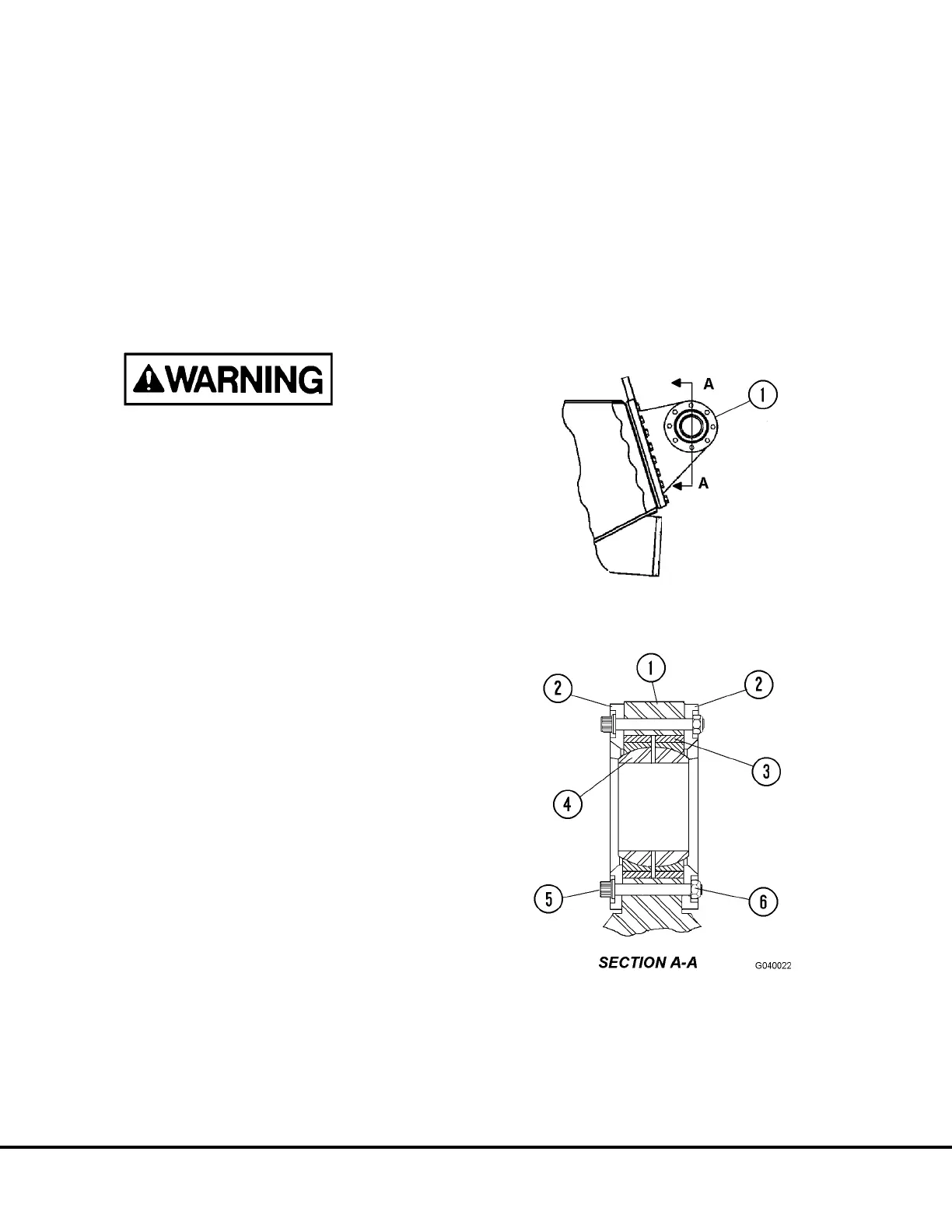

PIVOT EYE BEARING

Disassembly

1. Remove capscrews and locknuts (5 and 6, Figure

4-2). Remove bearing retainers (2). Setup an

appropriate tool to press spherical bearing (4)

from bearing carrier (3).

2. Inspect all parts and bearing for wear or damage.

Replace parts showing excessive wear or dam-

age.

Spherical bearing outer race O.D.:

8.7500 - 8.7488 in. (222.25 - 222.22 mm)

Bearing bore I.D.:

5.9990 - 6.0000 in. (152.37 - 152.40 mm)

3. If bearing carrier (3) is damaged or worn, refer to

“Pivot Eye Repair” for repair procedure.

Assembly

1. Setup an appropriate tool to press spherical bear-

ing (4, Figure 4-2) into bearing carrier (3). Be

certain bearing outer race is flush with bearing

carrier sides.

2. Install bearing retainers (2) with 12 point cap-

screws (5) and locknuts (6). Tighten capscrews

to 575 ft. lbs. (779 N.m) torque.

FIGURE 4-2. PIVOT EYE BEARING

INSTALLATION

1. Pivot Eye Structure

2. Bearing Retainer

3. Bearing Carrier

4. Spherical Bearing

5. 12 Pt. Capscrew

6. Locknut

G4-2 Rear Axle Housing Attachment G04014

Loading...

Loading...