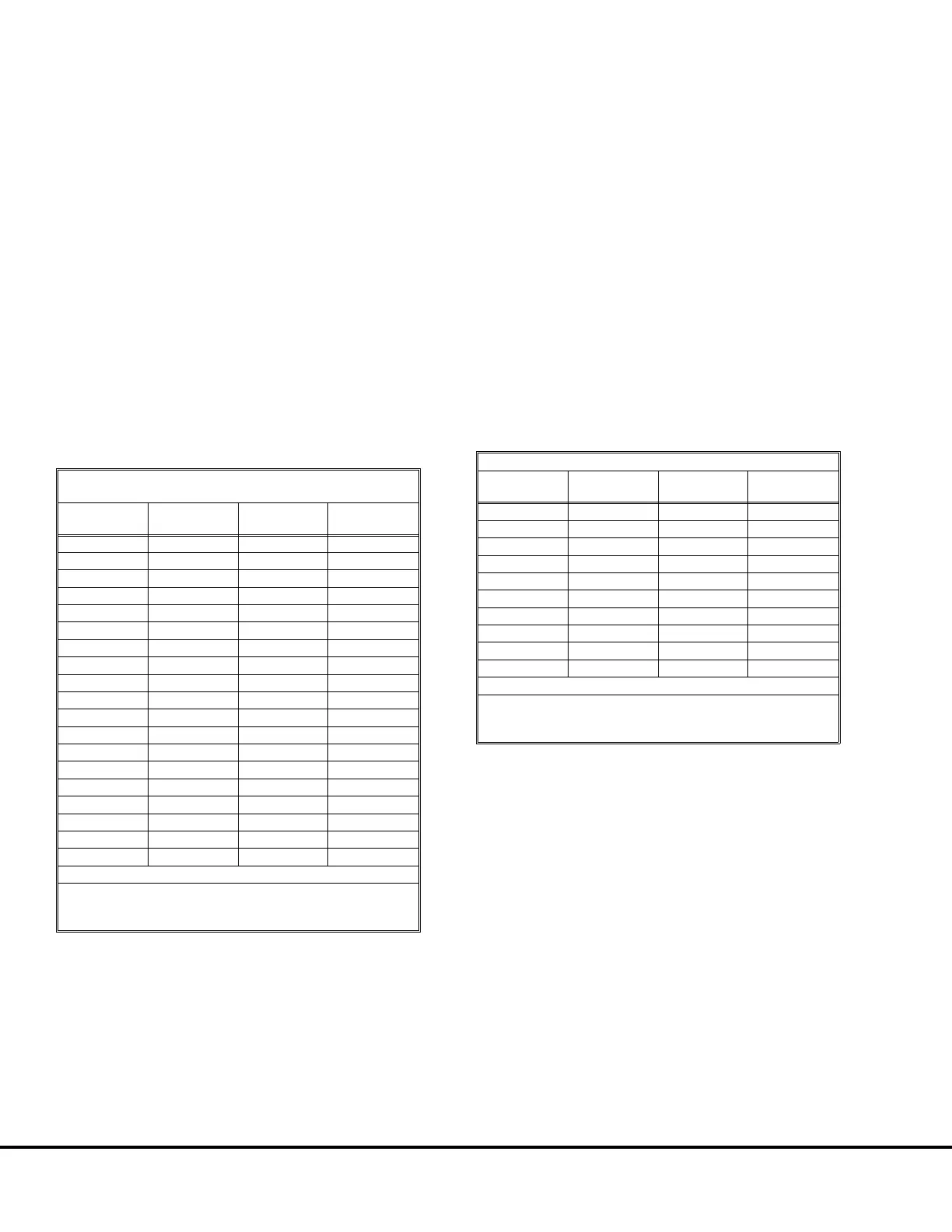

Standard Assembly Torques For

12-Point, Grade 9, Capscrews (SAE)

The following specifications appy to required assembly

torques for all 12-Point, Grade 9 (170,000 psi minimum

tensile), Capscrews.

• Capscrew threads and seats SHALL be lubricated

when assembled.

Unless instructions specifically recommend oth-

erwise, these standard torque values are to be

used with simple lithium base chassis grease

(multi-purpose EP NLGI) or a rust- preventive

grease (see list, this page) on the threads.

• Torques are calculated to give a clamping force of

approximately 75% of proof load.

• The maximum torque tolerance shall be ±10% of

the torque value shown.

TABLE II - STANDARD ASSEMBLY TORQUE

for 12-Point, Grade 9, Capscrews

CAPSCREW

SIZE*

TORQUE

ft. lbs.

TORQUE

N.m

TORQUE

kg.m

0.250 - 20 12 16 1.7

0.312 - 18 24 33 3.3

0.375 - 16 42 57 5.8

0.438 - 14 70 95 9.7

0.500 - 13 105 142 14.5

0.562 - 12 150 203 20.7

0.625 - 11 205 278 28.3

0.750 - 10 360 488 49.7

0.875 - 9 575 780 79.4

1.000 - 8 860 1166 119

1.000 - 12 915 1240 126

1.125 - 7 1230 1670 170

1.125 - 12 1330 1800 184

1.250 - 7 1715 2325 237

1.250 - 12 1840 2495 254

1.375 - 6 2270 3080 313

1.375 - 12 2475 3355 342

1.500 - 6 2980 4040 411

1.500 - 12 3225 4375 445

* Shank Diameter (in.) - Threads per in.

This Table represents standard values only.

Do not use these values to replace torque values which are

specified in assembly instructions.

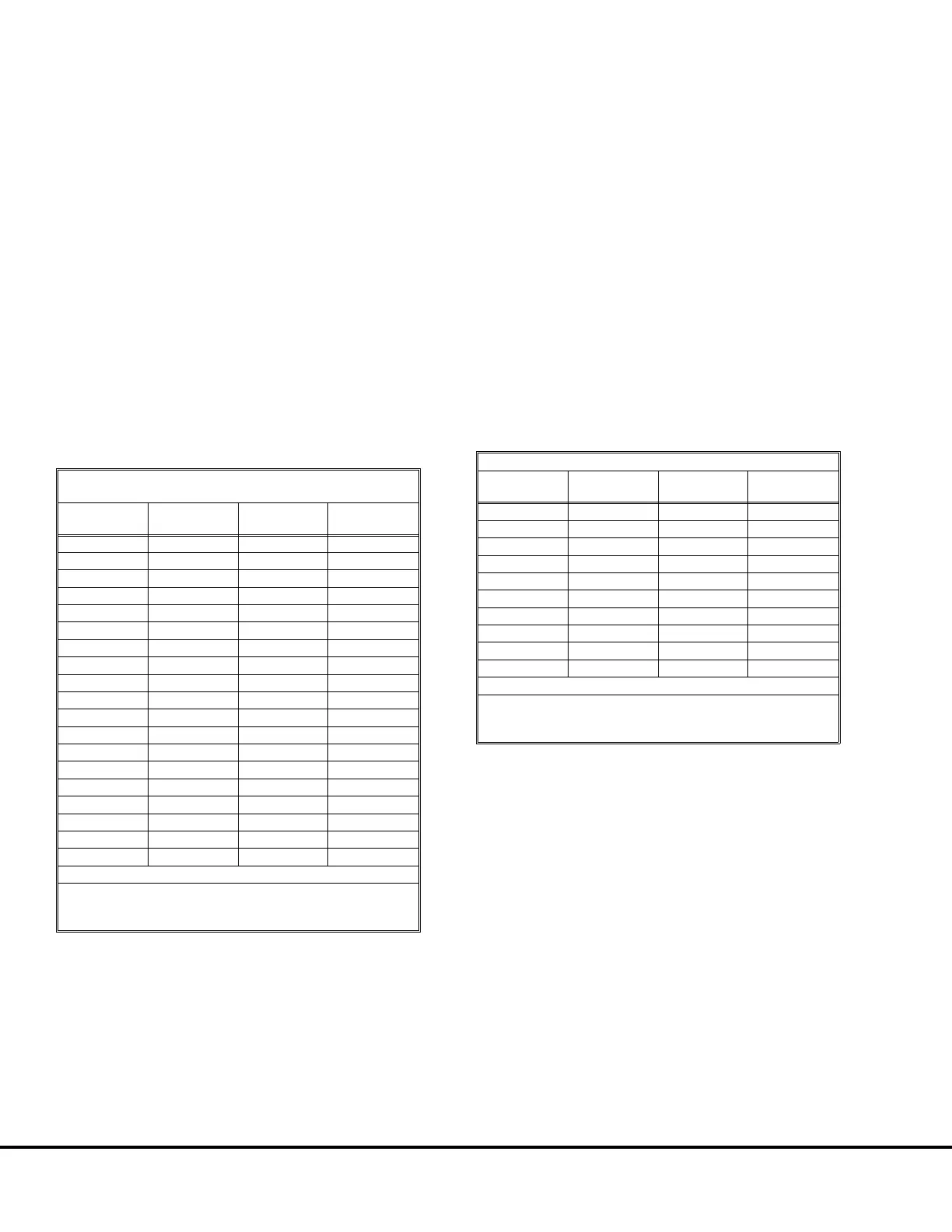

Standard Metric Assembly Torque For

Class 10.9 Capscrews & Class 10 Nuts

The following specifications appy to required assembly

torques for all meteric Class 10.9 finished hexagon

head capscrews and Class 10 nuts.

• Capscrews threads and seats SHALL NOT be

lubricated when assembled. These specifications

are based on all capscrews, nuts, and hardened

washers being

phosphate and oil

coated.

NOTE: If zinc-plated hardware is used, each

piece must be lubricated with a Rust Preventive

Grease or Lithium-base grease to achieve the

same clamping forces provided below.

• Torques are calculated to give a clamping force of

approximately 75% of proof load.

• The maximum torque tolerance shall be within

±10% of the torque value shown.

TABLE III - STANDARD METRIC ASSEMBLY TORQUE

CAPSCREW

SIZE*

TORQUE

N.m

TORQUE

ft. lbs.

TORQUE

kg.m

M 6 x 1 12 9 1.22

M 8 x 1.25 30 22 3.06

M10 x 1.5 55 40 5.61

M12 x 1.75 95 70 9.69

M14 x 2 155 114 15.81

M16 x 2 240 177 24.48

M20 x2.5 465 343 47.43

M24 x 3 800 590 81.6

M30 x 3.5 1600 1180 163.2

M36 x 4 2750 2028 280.5

* Shank Diameter (mm) x Threads per mm.

This Table represents standard values only.

Do not use these values to replace torque values which are

specified in assembly instructions.

SUGGESTED* SOURCES FOR

RUST PREVENTIVE GREASE:

• AMERICAN ANTI-RUST GREASE #3-X from

Standard Oil Company (also American Oil Co.)

• GULF NORUST #3 from Gulf Oil Company.

• MOBILARMA 355, Product No. 66705 from

Mobil Oil Corporation.

• RUST BAN 326 from Humble Oil Company.

• RUSTOLENE B GREASE from

Sinclair Oil Company.

• RUST PREVENTIVE GREASE - CODE 312 from

the Southwest Grease and Oil Company.

* NOTE: This list represents the current Engineering

approved sources for use in Haulpak manufacture. It

is not exclusive. Other products may meet the same

specifications of this list.

A5-2 Standard Torque Charts and Tables A05001 03/01

Loading...

Loading...