3. Depress the charging valve core to release nitro-

gen pressure from the suspension. When nitro-

gen pressure has been vented to atmosphere,

loosen and remove the charging valve. The sus-

pension should have collapsed slowly as gas

pressure was released. Truck weight is now sup-

ported by the support blocks.

4. Use a plastic tube to help bleed off trapped air

inside the piston. Remove vent plugs and the

bleeder screw. Service the suspension with clean

HYDRAIR

®

Oil until clean oil comes out of the port

where the bleeder screw and plug were removed

from the side of the housing. Drip pans should be

used and all spillage cleaned from outside of

suspension. Allow suspension to stand for at least

15 minutes to clear any trapped nitrogen and/or

air bubbles from the oil. Add oil if necessary.

Loosely install charging valve.

Rear Suspension Nitrogen Charging

Lifting equipment (overhead or mobile cranes, or

hydraulic jacks) must be of sufficient capacity to

lift the truck weight. Be certain that all personnel

are clear of lift area before lift is started.

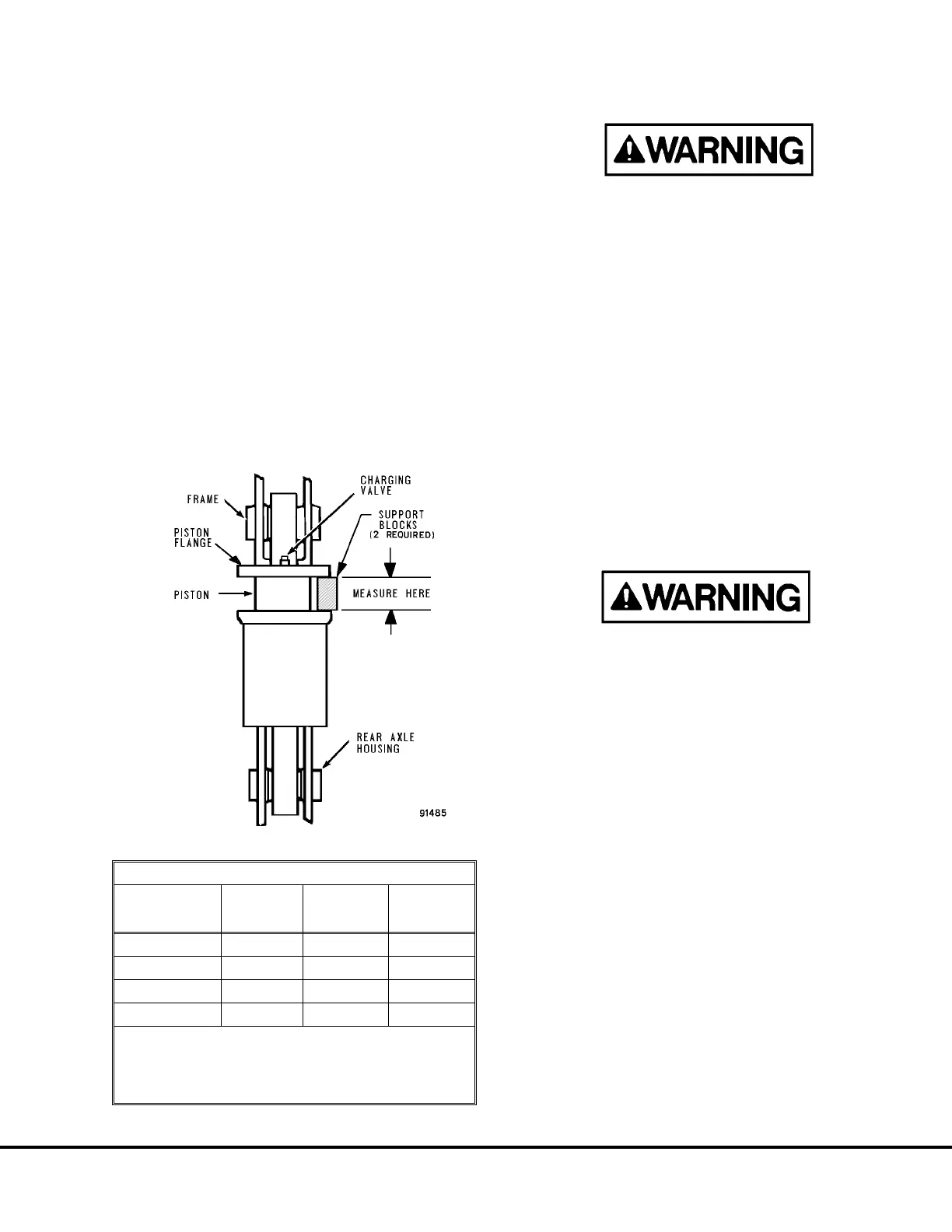

1. With nitrogen charging support blocks at hand

(see Figure 4-4), proceed as follows:

a. With overhead crane or jacks raise the truck

frame to provide clearance for blocks.

b. Install nitrogen charging dimension blocks; se-

cure blocks so they will not fly free.

c. Lower truck frame until the blocks are firmly and

squarely seated between the piston flange and

cylinder housing.

NOTE: Prevent damage to plated surface, oil seals

and capscrew heads.

Dry nitrogen is the only gas approved for use in

HYDRAIR

®

II suspensions and accumulators.

Charging of these components with oxygen or

other gases may result in an explosion which

could cause fatalities, serious injuries and/or ma-

jor property damage.

Use only nitrogen gas meeting the specifications

on the “Nitrogen Specifications Chart”.

2. Install charging valve, with a new lubricated seal-

ing O-ring (9, Figure 4-2) (use fresh HYDRAIR

®

oil). Tighten valve body (large hex) (6) to 16.5 ft.

lbs. (22.4 N.m) torque. The valve swivel nut (4)

(small hex) must be unseated (counterclockwise)

about three full turns.

3. Install HYDRAIR

®

Charging Kit and bottle of pure

dry nitrogen. Following previous instructions,

charge the suspensions with nitrogen gas to the

pressure shown in Figure 4-4 for the truck being

serviced. DO NOT use an overcharge of nitrogen

gas to lift the suspension off the blocks.

4. Shut off gas pressure and remove charging kit

components.

FIGURE 4-4. REAR SUSPENSION

REAR SUSPENSION DIMENSIONS (EMPTY)

TRUCK

MODEL

& OPTIONS

OILING

HEIGHT

in. (mm)

CHARGING

HEIGHT

in. (mm)

CHARGING

PRESSURE

psi (kPa)

730E* 1.0 (25.4) 9.0 (229) 280 (1931)

830E* 1.0 (25.4) 9.5 (241) 250 (1724)

830E** 1.0 (25.4) 9.5 (241) 315 (2172)

930E*, E-2* 1.0 (25.4) 7.5 (190) 215 (1482)

* with Standard Rock Body

** with Combination Body /Tailgate

Note: If truck starts to lift off blocks before charging

pressure is attained, STOP CHARGING.

H04005 9/99 Oiling and Charging Procedures H4-5

730E, 830E, and 930E

Loading...

Loading...