13. Slowly depress plunger to obtain pressure shown

in Table I on the “B1” pressure gauge:

Adjust screw plug in bottom port of differential

pressure switch counterclockwise until

switch contacts just close.

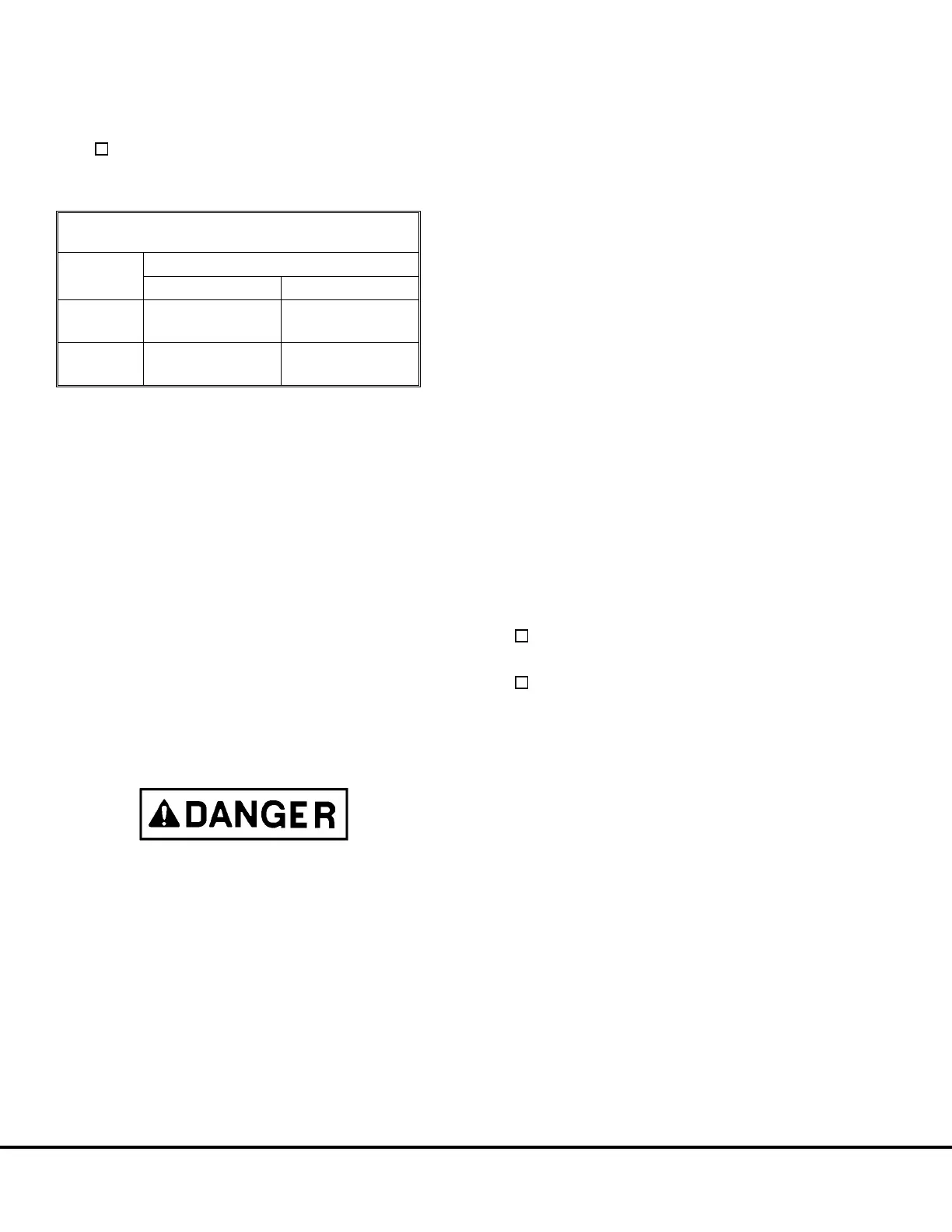

Table I - Differential Pressure Switch

Adjustment

Spring

Color

Pressure - Switch Contacts Closing

“B1” Valve Spool “B2” Valve Spool

Red

300 ±30 psi

(2 068 ±207 kPa)

300 ±30 psi

(2 068 ±207 kPa)

Green

600 ±50 psi

(4 137 ±345 kPa)

600 ±50 psi

(4 137 ±345 kPa)

14. Release plunger and depress again while observ-

ing “B1” gauge and ohmmeter to verify switch

contacts close at the pressure in Table I.

If not, repeat step 13.

15. Insert pry bar under pivot pin to actuate the “B2”

section of valve.

16. Slowly depress plunger while observing ohmme-

ter; switch contacts should close at the pressure

in Table I on the “B2” gauge. A slight adjustment

may be necessary.

17. Slowly depress both plungers equally from mini-

mum to maximum application pressure. Switch

contacts must remain open.

18. Install plug (6) and tighten to 90 - 100 in. lbs. (10.2

- 11.3 N.m) torque.

19. Shut down the test bench and relieve all hydraulic

pressure from the lines.

Avoid spillage and contamination! Avoid contact

with hot oil if the machine has been operating. The

oil will be at very high pressure.

Hydraulic fluid escaping under pressure can have

sufficient force to enter a person’s body by pene-

trating the skin and cause serious injury and pos-

sibly death if proper medical treatment by a

physician familiar with this injury is not received

immediately.

20. Remove hoses from valve and remove valve from

test stand. Refer to instructions below for pedal

actuator installation prior to final test.

Final Test and Adjustment

The brake pedal actuator must be installed on the

brake valve body prior to final test and adjustment.

Refer to “Installation of Brake Pedal Actuator to Brake

Valve”.

NOTE: The “Final Test and Adjustment” procedure

can also be performed with the brake valve installed in

the truck. To perform final test with brake valve

mounted in the truck, install valve per instructions in

“Installation”. Install 3000 psi (20 682 kPa) gauges at

the “B1” and “B2” diagnostic test connectors in the

brake cabinet. Follow steps 21. - 33. below for final

test.

21. Reinstall brake valve (with actuator pedal at-

tached) on the test stand following steps 2

through 9. under “Test Setup Procedure”.

22. With test stand pump adjusted for 2750 psi

(18,960 kPa) or with engine running and brake

system supply pressure at or above 2750 psi (18,

960 kPa), depress the pedal as quickly as possi-

ble. The pressure on the output circuits must

reach the minimum pressure listed below at port

“B1” and port “B2” within 1.0 second. Measure-

ment of time begins the moment force is applied

to move the pedal.

Rear Brake - “B1”: 2400 ±75 psi

(16,545 ±517 kPa)

Front Brake - “B2” : 2400 ±75 psi

(16,545 ±517 kPa)

23. With “B1” and “B2” plugged into a strip chart

recorder, (if available) check the modulation by

slowly applying pressure until the maximum pres-

sure is reached. Make sure the pressure increase

is smooth and no sticking of the spools is ob-

served. Fully depress the pedal. Pressures must

remain within specification at “B1” and “B2” for

20 seconds.

24. Adjust set screw (21, Figure 3-10) until the set

screw is not touching the actuator cap. Apply

Loctite

®

242 to the adjustment screw prior to

setting the deadband.

25. Set the deadband by placing a 0.010 in (0.254

mm) thick shim at location (9) between the pedal

structure and return stop boss on pivot structure.

26. Adjust the set screw (21) until the set screw is just

touching the cap.

J3-12 Brake Circuit Component Service J03019 1/99

Loading...

Loading...