Swashblock Group

11. Inspect swashblock (25, Figure 6-14) for

scratches, grooves, cracks or uneven surface.

Replace if defective.

NOTE: The wear face is coated with a gray colored

epoxy based dry film lubricant for break-in purposes.

Scratching or wear of this coating is not detrimental as

long as the metal surface underneath the coating is not

scored or “picked-up”.

12. Compare saddle bearing (24) thickness in wear

area to thickness in a non-wear area. Replace

saddle bearings if difference is greater than 0.004

in (0.102 mm).

13. Check mating surface of swashblock for cracks or

excessive wear. Replace if necessary.

14. Swashblock movement in saddle and saddle bear-

ing must be smooth.

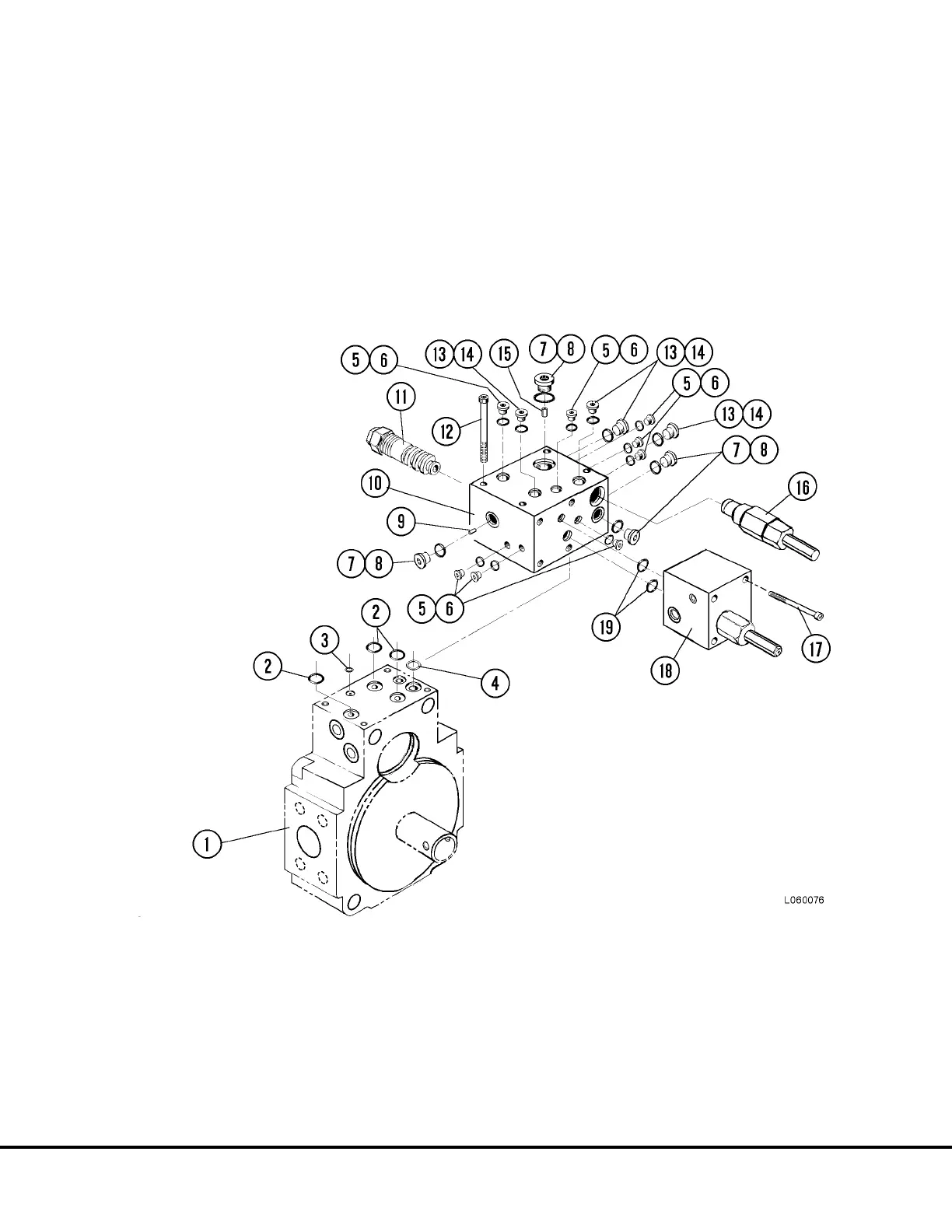

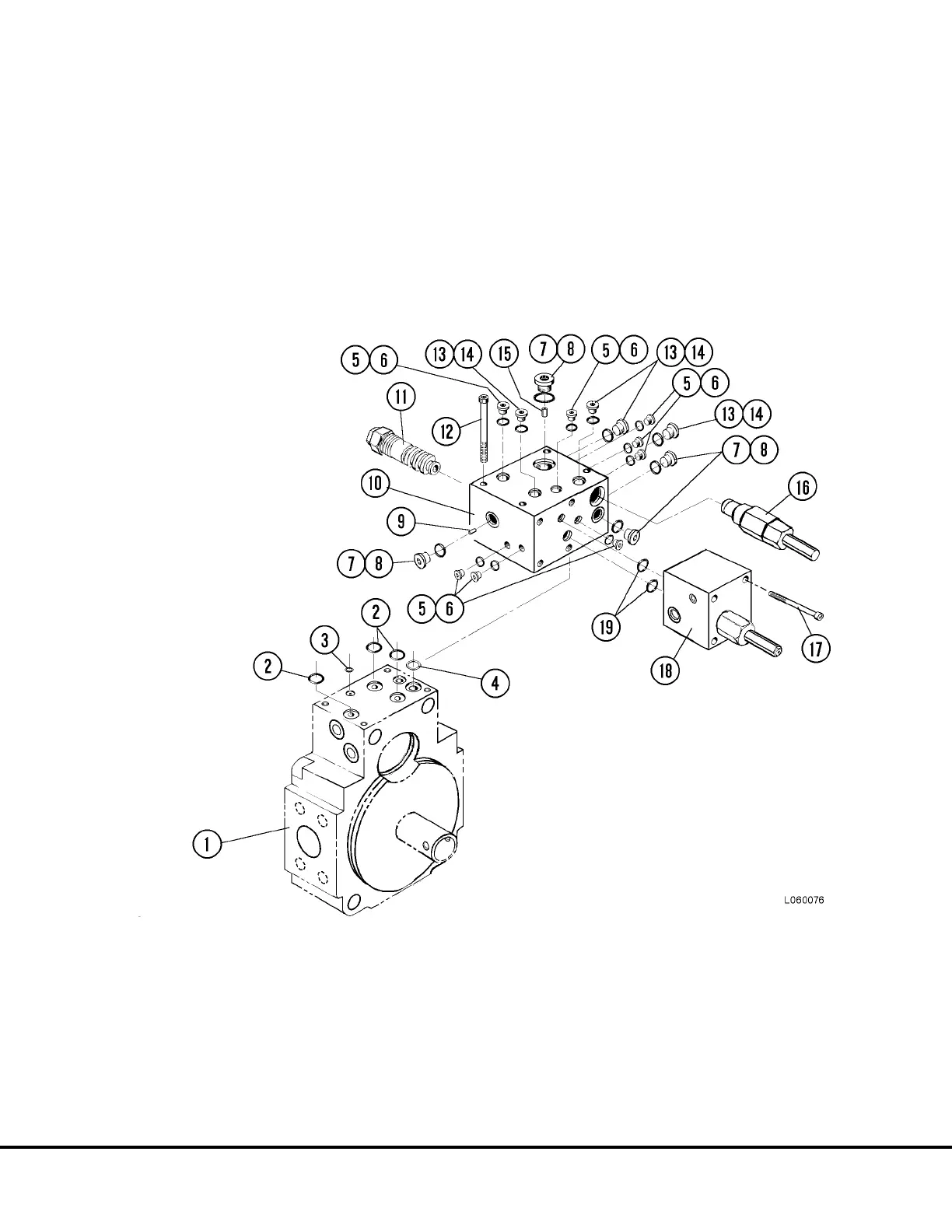

FIGURE 6-16. UNLOADER & COMPENSATOR CONTROLS

1. Valve Plate

2. O-Ring

3. O-Ring

4. O-Ring

5. Plug

6. O-Ring

13. Plug

14. O-Ring

15. Orifice (0.032 in.)

16. Compensator

17. Screw

18. Unloader Module

19. O-Ring

7. Plug

8. O-Ring

9. Orifice (0.062 in.)

10. Compensator Control Block

11. 4-Way Valve

12. Screw

L06021 Steering Circuit Component Repair L6-19

Loading...

Loading...