REAR SUSPENSIONS

The HYDRAIR

®

II suspensions are hydro-pneumatic

components containing oil and nitrogen gas. The oil an

gas in the four suspensions carry the gross truck

weight less wheels, spindles and final drive assembly.

The rear suspension cylinders consist of two basic

components; a suspension housing attached to the

rear axle housing, and a suspension rod attached to

the frame.

The HYDRAIR

®

II suspension cylinder requires only

normal care when handling as a unit. However, after

being disassembled these parts must be handled care-

fully to prevent damage to the machined surfaces.

Surfaces are machined to extremely close tolerances

and are precisely fitted. All parts must be completely

clean during assembly.

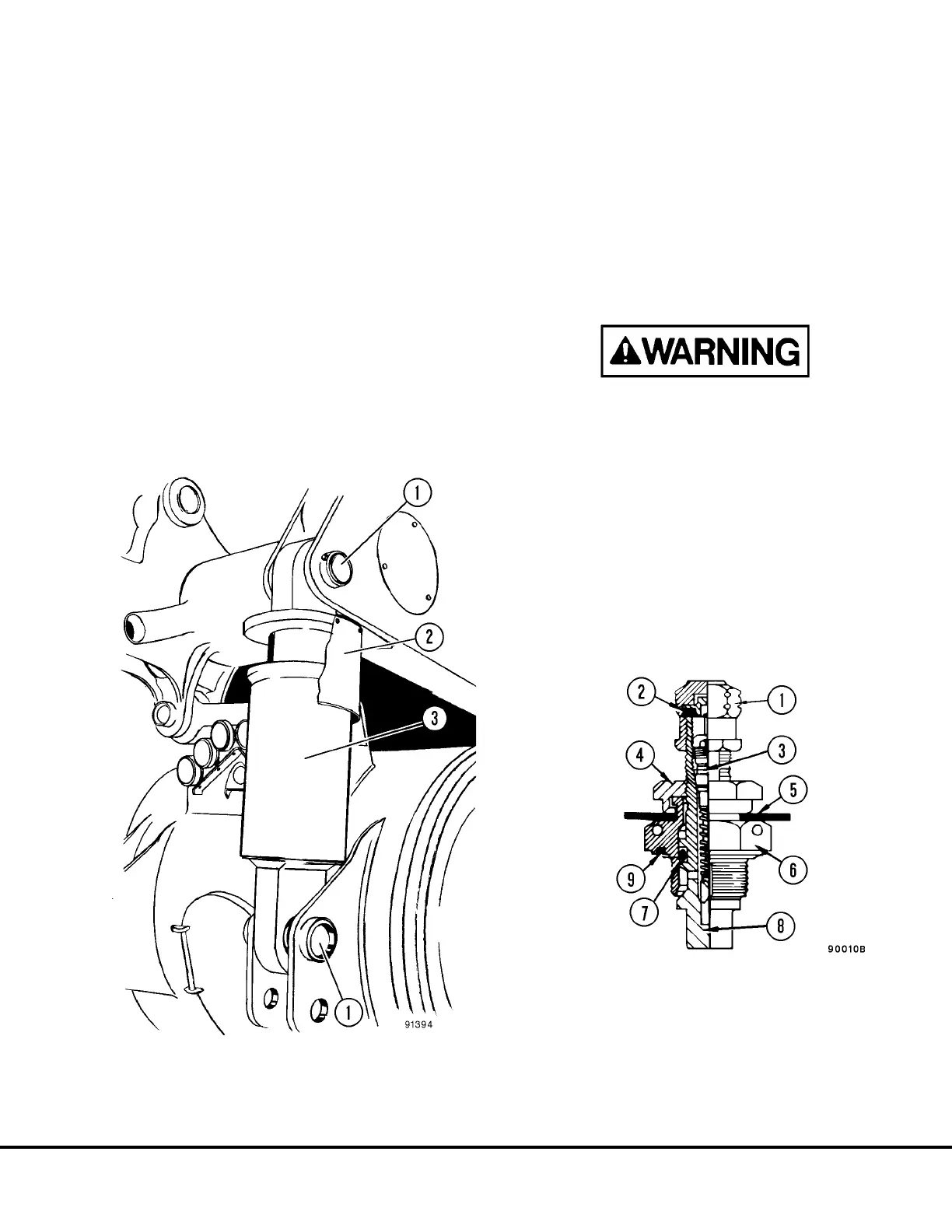

Removal

1. Remove capscrews, washers, and metal shield

(2, Figure 3-1) from the suspension.

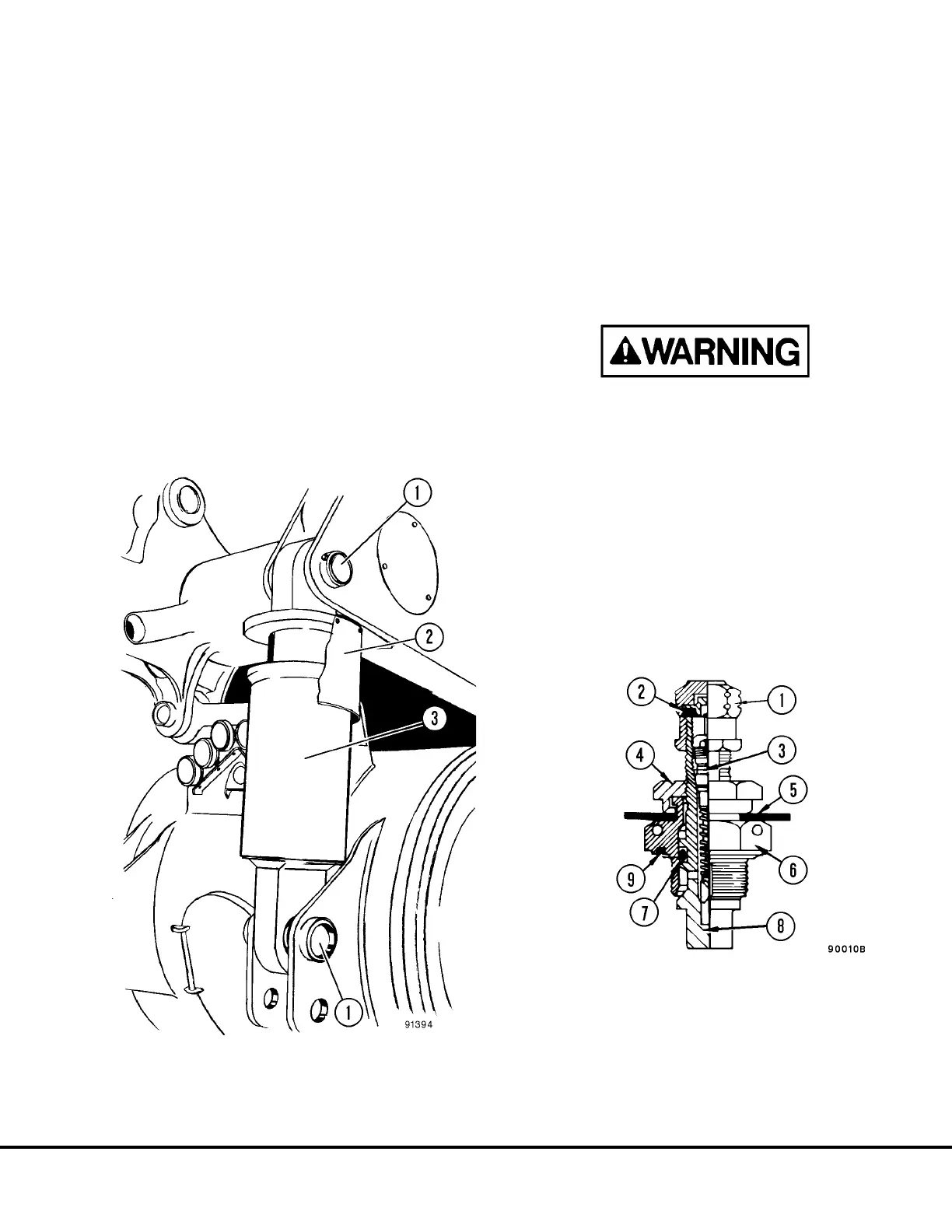

2. Remove charging valve cap, (1, Figure 3-2)

loosen small hex (4) on charging valve and turn

counterclockwise three full turns to unseat valve

seal. Connect suspension charging kit.

Make certain only the swivel nut turns. Turning the

complete charging valve assembly may result in

the valve assembly being forced out of the suspen-

sion by the gas pressure inside.

3. If necessary, charge the suspension to be re-

moved with dry nitrogen until the rod is exposed

approximately 5.0 in. (127 mm).

4. Place stands or cribbing under the truck frame at

each hoist cylinder mount.

FIGURE 3-1. REAR SUSPENSION INSTALLATION

1. Mounting Pins

2. Piston Rod Shield

3. Suspension Cylinder

FIGURE 3-2. CHARGING VALVE

1. Valve Cap

2. Seal

3. Valve Core

4. Swivel Nut

5. Rubber Washer

6. Valve Body

7. O-ring

8. Valve Stem

9. O-ring

H03013 Rear Suspensions H3-1

Loading...

Loading...