9.11.4 Diagnoscs

The controlled node indicates applied diagnosc data by an emergency message to the man-

aging node.

Details

•

The XXXX parameter serves to suppress the transmission of emergency messages to the

managing node. Thus, errors of a certain type can be suppressed in a targeted way.

•

Errors and warnings of the inverter and the network opon are sent as extended diagnos-

c messages to the managing node:

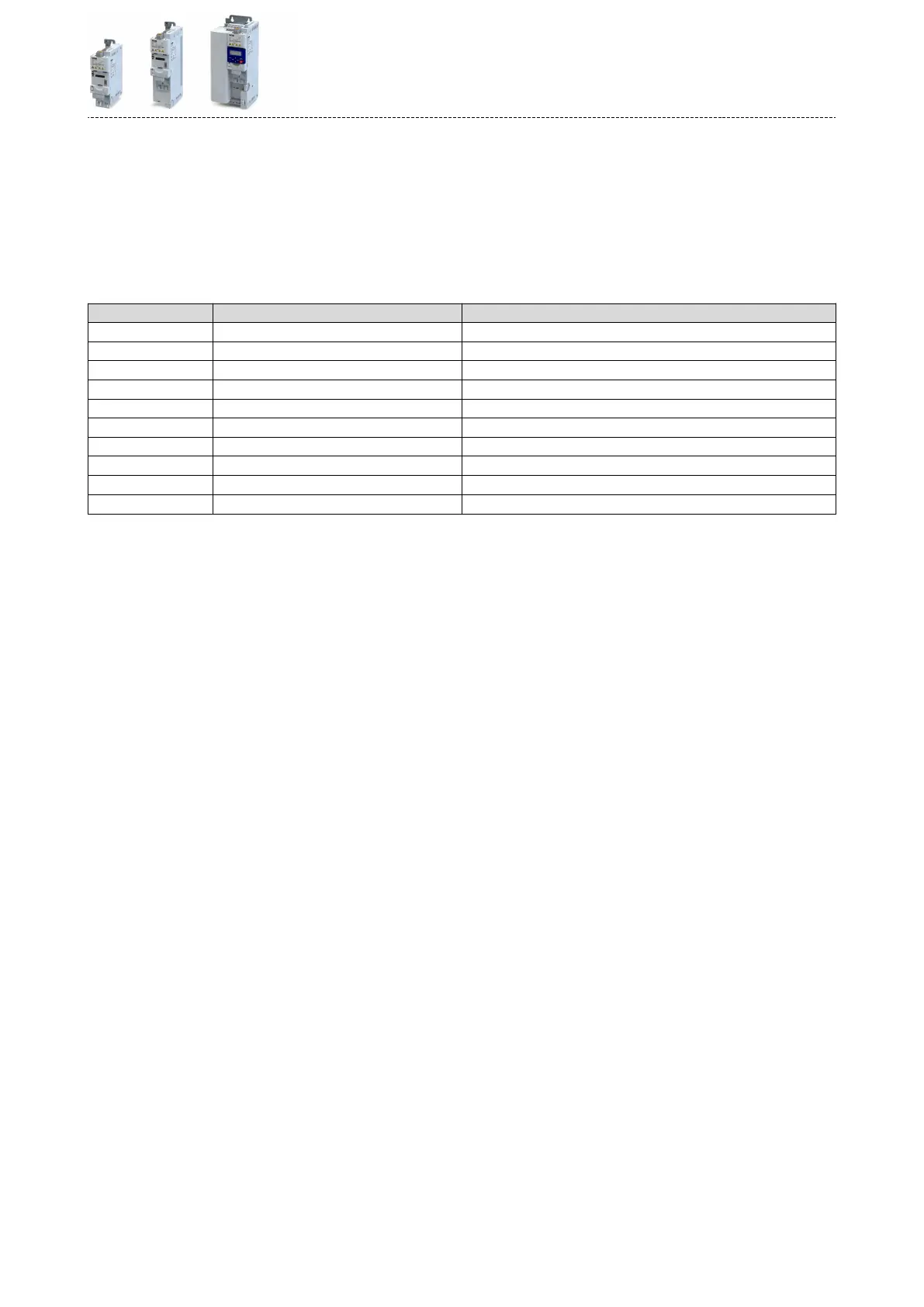

Bytes Meaning Value [hex]

1 ... 6 Diagnosc block header 0x0010 001C 0100

7 ... 8 Alarm type 0x0001 (diagnoscs)

9 ... 12 API (Applicaon Programming Interface) 0x0000 0000

13, 14 Slot number 0x0001 / 0x0002

15, 16 Subslot number 0x0001

17 ... 20 Module ID ID according to module

21 ... 24 Submodule number ID according to module

25, 26 Alarm specicaon 0xB000

27, 28 User structure ID 0x0001

29 ... 32 Error code

4Error codes ^ 639

9.11.5 Process data transfer

POWERLINK transfers process data, parameter data, conguraon data and diagnosc data

between the managing node and the involved controlled nodes. Depending on their me-crit-

ical behaviour, the data is transmied via corresponding communicaon channels.

Details

•

Process data is transmied cyclically between the managing node and the controlled node

(permanent exchange of current input and output data).

•

The transfer of process data is me-crical.

•

The process data serves to control the POWERLINK nodes.

•

The process data can be directly accessed by the managin node. The data in the PLC, for

instance, are directly stored in the I/O area.

•

The contents of the process data are dened via I/O data mapping.

•

Process data are not saved in the device.

Process data (RxPDO):

•

0x4008:001 (P590.01) (NetWordIN1)

•

0x400B:013 (P592.13) (Network frequency setpoint [+/-16384])

Process data (TxPDO):

•

0x400A:001 (P591.01) (NetWordOUT1)

•

0x400C:009 (P593.09) (Frequency [+/-16384])

•

0x2D88 (P104.00) (Motor current)

•

0x4050:002 (internal parameters)

Conguring the network

POWERLINK

Process data transfer

399

Loading...

Loading...