Setting cutting conditions

The following describes how to establish cutting conditions for cutter 2 (tangential cutter) as an

example.

Once you have set cutting conditions, execute the [TEST CUT] function to check whether or not the

cutting conditions are proper. (See page 2.35.)

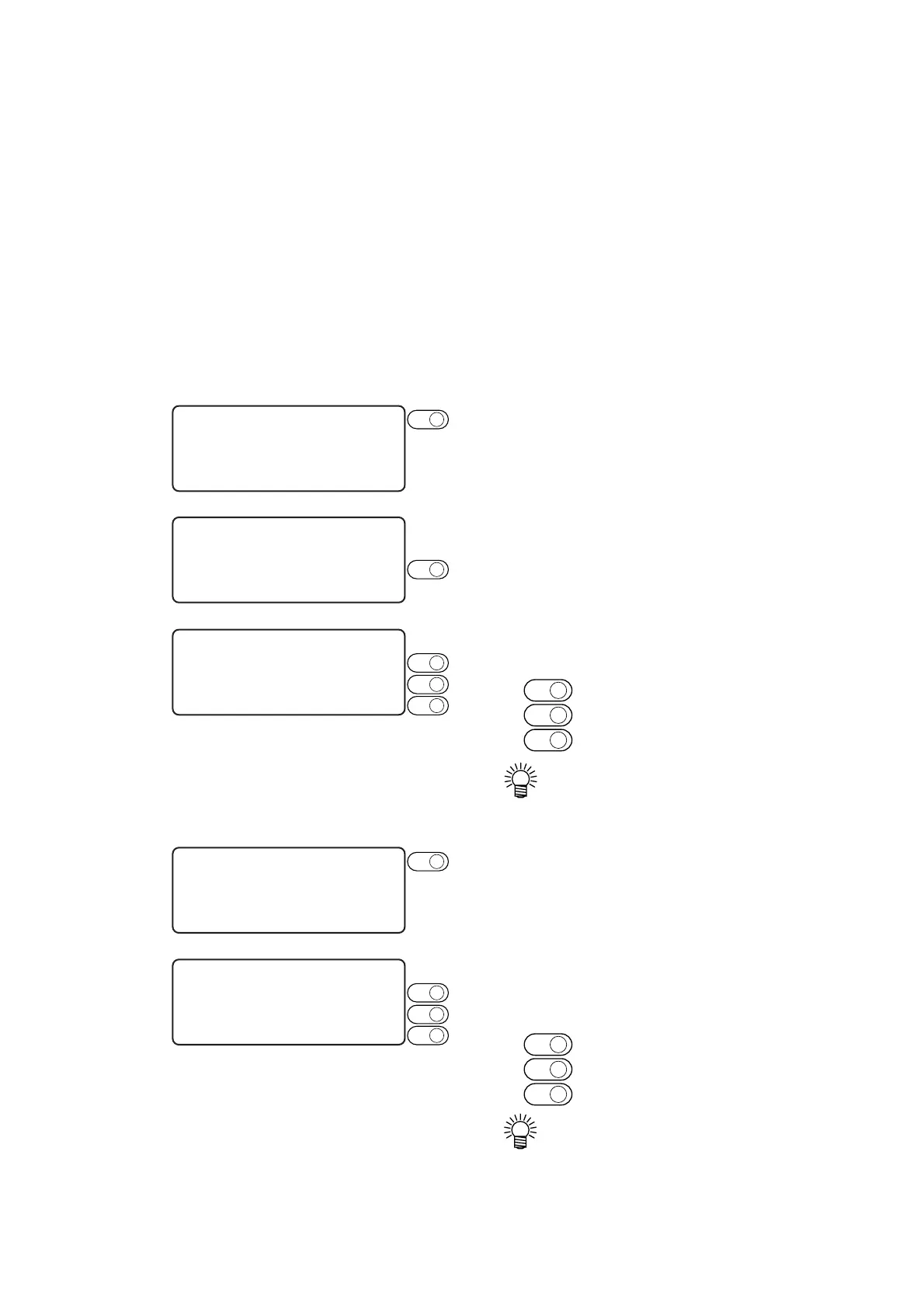

1 Select the head and the tool in the

[TOOL SELECT]. (See page 2.26.)

Select B for the head and cutter 2 for the

tool.

2 Invoke the 1st page of the LOCAL

MENU.

3 Select the [CONDITION].

Select the CONDITION, and the cutting

conditions for the cutter 2 will appear on

the screen.

4 Set the speed, pressure and accelera-

tion to adequate values.

F1

+

..... Input a speed.

F2

+

..... Input a pressure.

F3

+

..... Input an acceleration.

• If the “– (minus)” key of the respec-

tive function keys is pressed, a

previous value is indicated on the

display.

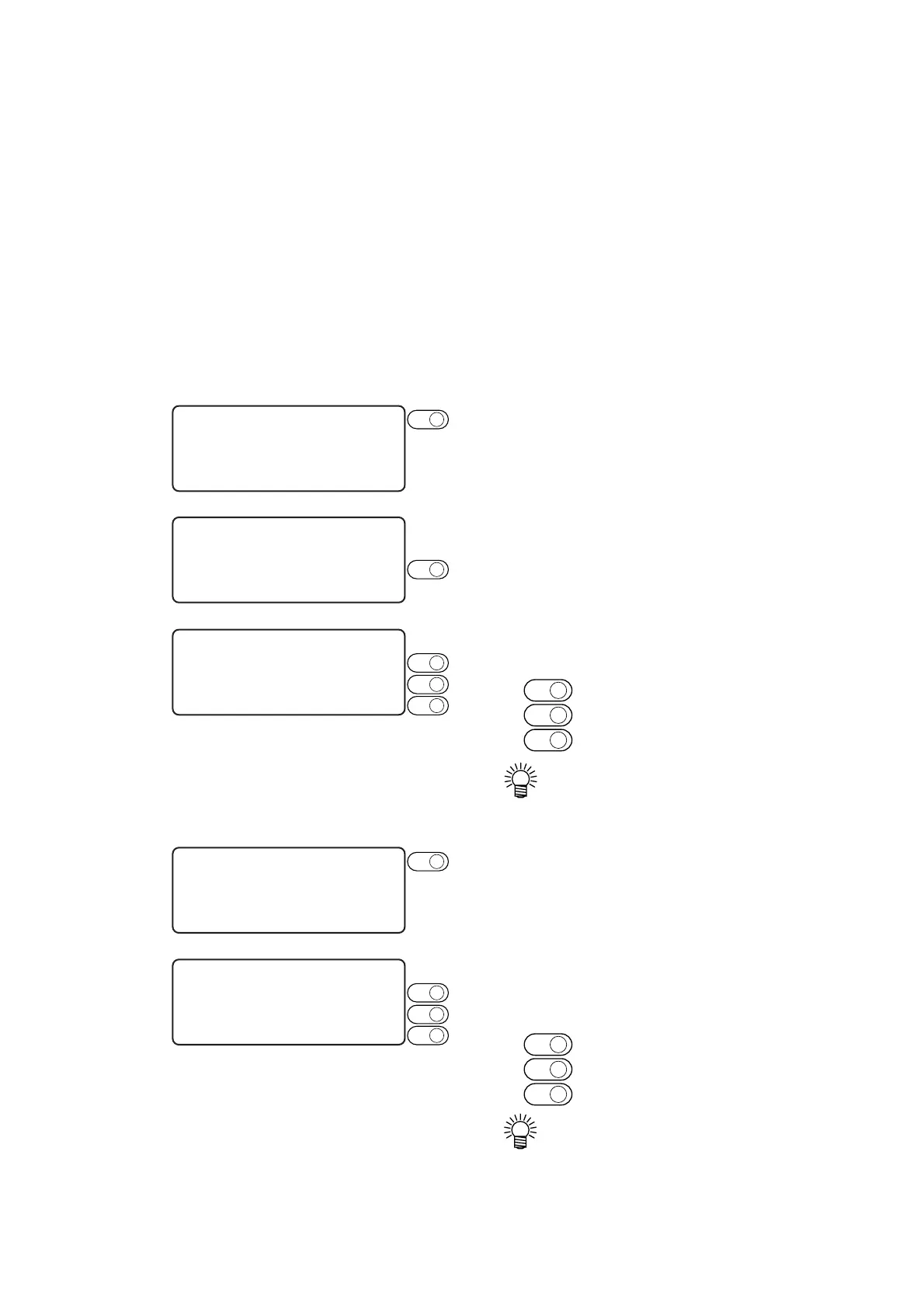

5 Invoke the 2nd page of the cutting con-

ditions screen for cutter 2.

6 Set the [START CORRECTION],

[END CORRECTION] and [UP

ANGLE] to adequate values.

F1

+

..... Input a start correction.

F2

+

..... Input an end correction.

F3

+

..... Input an up angle.

• If the “– (minus)” key of the respec-

tive function keys is pressed, a

previous value is indicated on the

display.

[ LOCAL ] 1 / 4

TOOL SELECT ———>

CONDITION ———>

TEST CUT ———>

PAGE

+

[ LOCAL ] 1 / 4

TOOL SELECT ———>

CONDITION ———>

TEST CUT ———>

< CUTTER 2 > 1 / 4

SPEED ∗40 cm/s >

PRESSURE ∗400 g >

ACCELE ∗0.4 G >

< CUTTER 2 > 1 / 4

SPEED 50 cm/s >

PRESSURE 900 g >

ACCELE 0.3 G >

F2

+

F3

+

F1

+

F2

+

PAGE

+

< CUTTER 2 > 2 / 4

F OFFSET ∗0.50 mm >

E OFFSET ∗0.50 mm >

UP ANGLE ∗30° >

F3

+

F1

+

F2

+

Loading...

Loading...