352 Rockwell Automation Publication 7000L-UM301F-EN-P - March 2020

Chapter 5 Component Definition and Maintenance

Drive Processor Module Replacement

Before replacing the Drive Processor Module, it is important to record all of the

programmed drive parameters and settings. Specifically, the parameters, fault

masks, fault descriptions, and PLC links are critical. This information is stored in

NVRAM on each, and as a result you may lose your settings with a new board.

The best method to record parameters is to use the memory on the terminal.

Other options include a flashcard, HyperTerminal, the door-mounted printer, or

DriveTools™ software to record the parameters to a file. The printer and

HyperTerminal options allow you to print all of the drive setup information.

Otherwise, recording information by hand is the only option left. In the situation

where a board has failed, you probably will not be able to save parameters after

the failure. That is why it is important to save all parameters when you are

finished commissioning or servicing the drive. In this case you should contact the

customer to see if they have a copy of the last parameters, or contact Product

Support to check if they have a copy.

Instructions to Replace the Drive Processor Module

1. Record all drive setup information using any of the options above, if

possible.

2. Ensure that all medium voltage and control voltage power to the drive is

isolated and locked out.

3. It is required to first remove the transparent sheet on top of the Drive

Processor Module by removing the 4 screws.

4. Use static strap before removing any connectors.

5. Remove the connectors J4, J11 and J12 after proper identification and

marking if necessary. Use the electrical drawing as the reference.

6. Remove the 4 screws on the corners of the board fastening the board to the

standoffs on the Analog Control Board ACB.

7. Gently remove the Drive Processor Module from the four, 34 pin female

connectors and one, 16 pin female connector on the ACB.

8. Remove the DIM module from the DPM and plug it on the new DPM

before the replacement of DPM.

9. Follow Steps 7 – 3 in reverse to re-install the boards back into the low

voltage control cabinet.

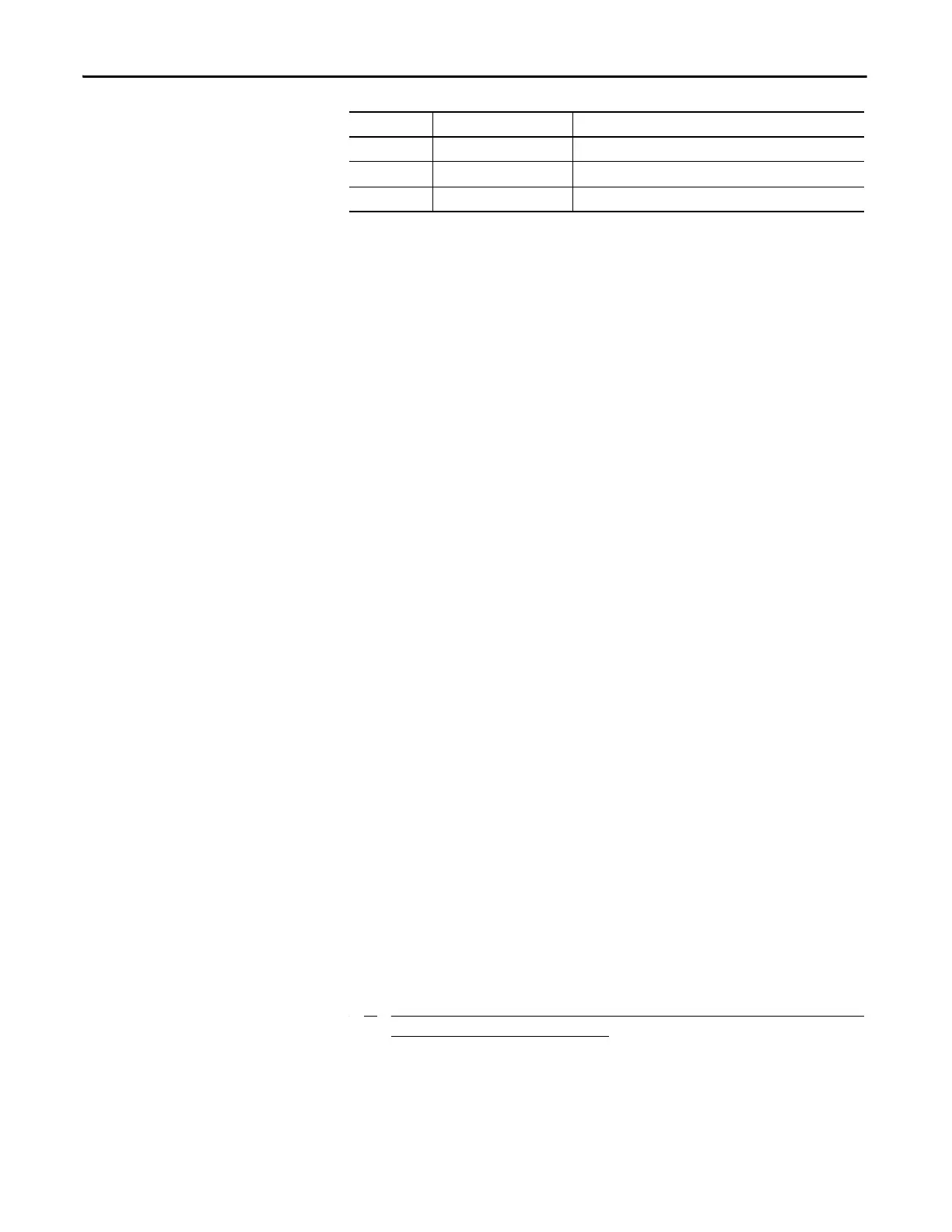

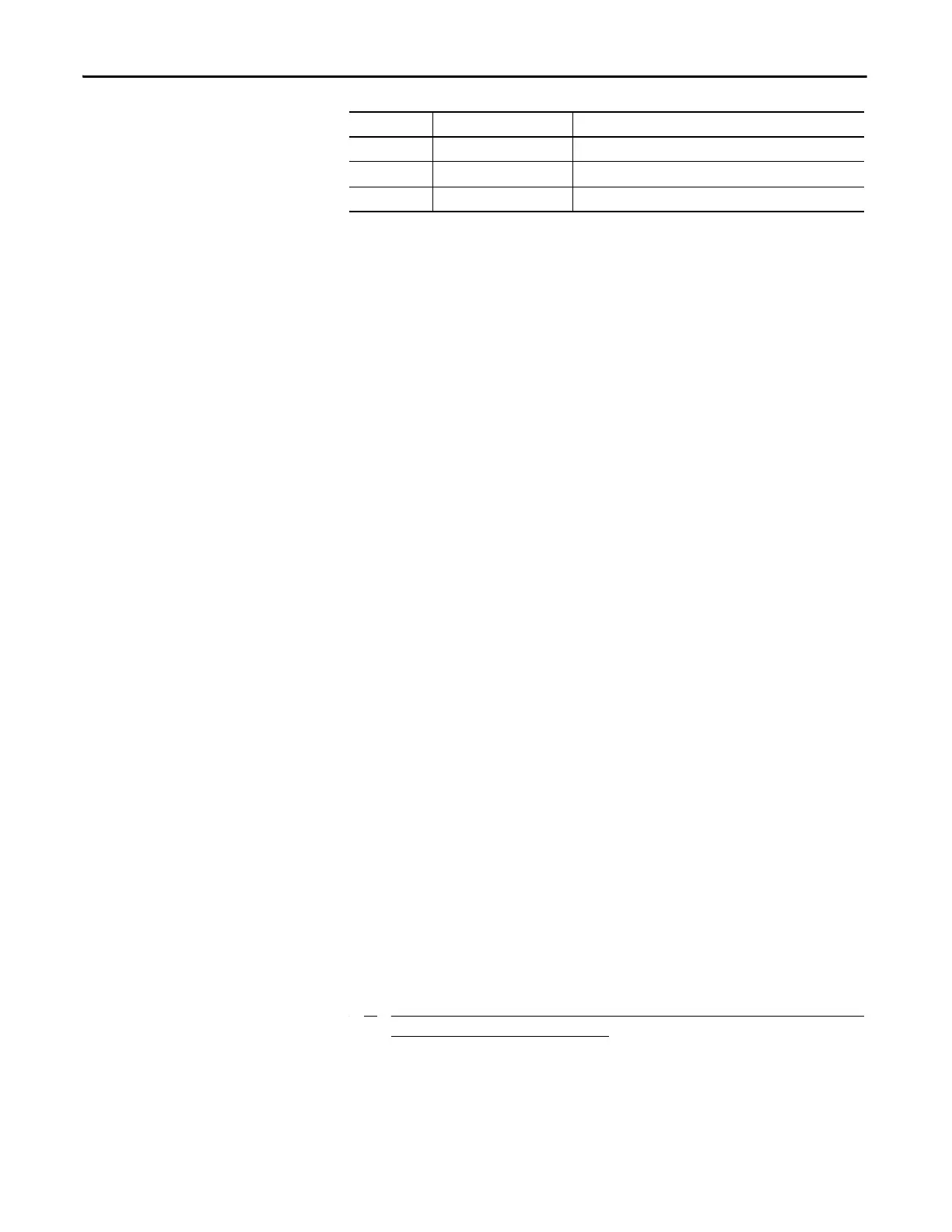

Red 10 Count End of Code Reached

Red 11 Count Download – CRC Error

Red 14 Count Download – Overflow Error

Color Rate or Count (Pulse) Meaning

Loading...

Loading...