10.2.2 Malfunctions of the water systems (XX10NN to XX19NN)

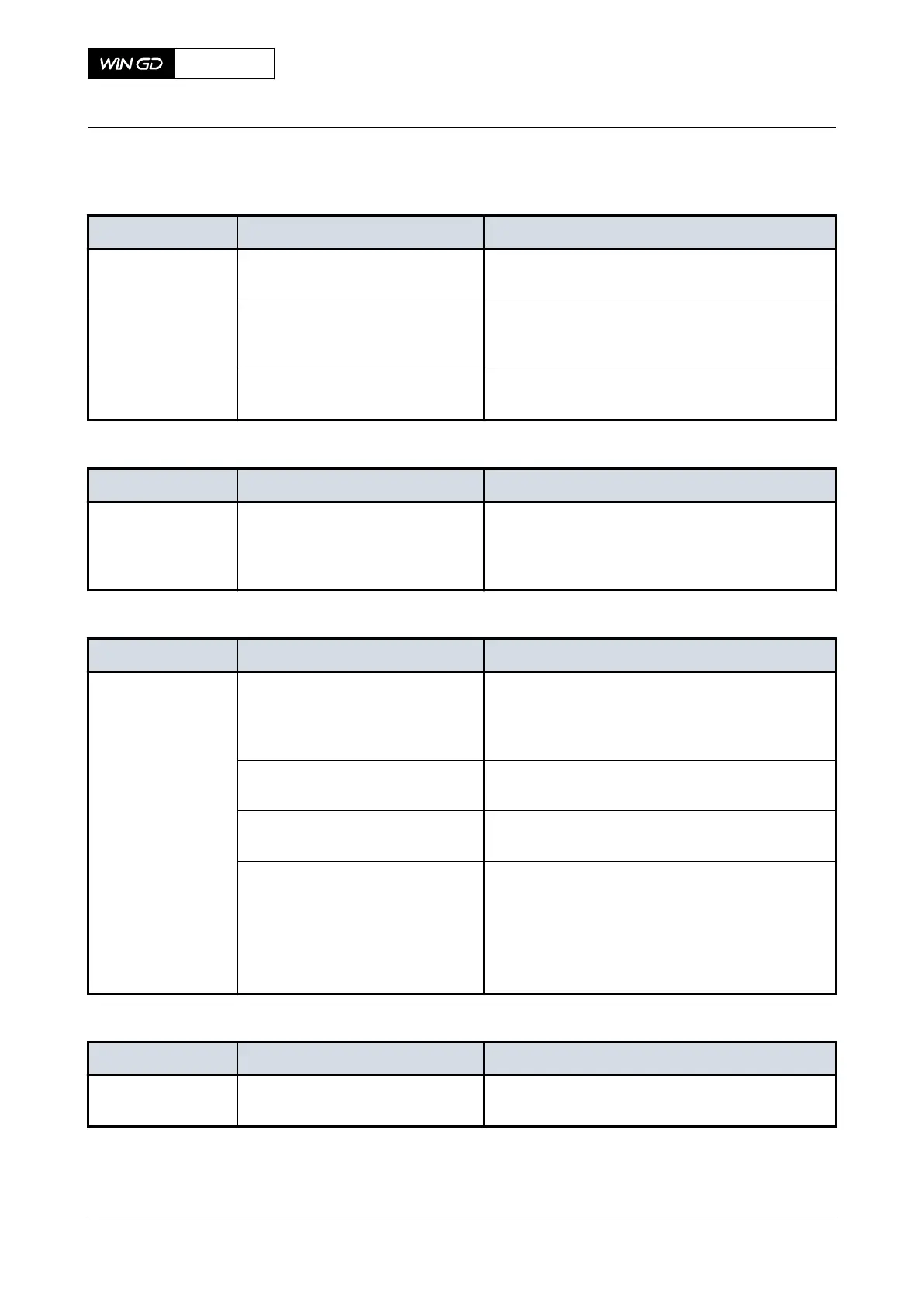

Tab 10-1 Supply pressure of the cylinder cooling water is too low

Indication Possible cause Procedure

PT1101A The cooling water supply system

is defective

•

Find the cause and repair the fault.

There are leaks in the cooling wa-

ter system (for example cracks in

a cylinder liner)

•

Find the cause and repair the fault.

For X92DF, the booster pump is

defective

•

Repair the booster pump.

Tab 10-2 Supply temperature of the cylinder cooling water is too low

Indication Possible cause Procedure

TE1111A The cooling water supply system

is defective

•

Find the cause and repair the fault. Adjust

the cooling water temperature slowly. This

prevents damage caused by sudden tem-

perature change.

Tab 10-3 Cylinder cooling water temperature downstream of a cylinder is too high

Indication Possible cause Procedure

TE1121-nnA This is a result of the malfunction

in Table 10-1 - Supply pressure of

the cylinder cooling water is too

low

•

Do the repair shown there.

The cooling water supply temper-

ature is too high

•

Find the cause and repair the fault.

A cylinder liner, cylinder cover or

exhaust valve cage is defective

•

Find the cause and repair the fault.

A piston ring is defective

•

As a temporary procedure, cut out the in-

jection of the related cylinder.

•

As a temporary procedure, increase the

feed rate of the cylinder oil of the related

cylinder.

•

Repair or replace the piston rings.

Tab 10-4 Supply pressure of the cooling water to the SAC is too low

Indication Possible cause Procedure

PT1361A The cooling water supply system

is defective

•

Find the cause and repair the fault.

X92DF

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 515 - Issue 002 2020-08

Loading...

Loading...