PROCEDURE

1 Do a check of the level switch LS3426A (if applicable also LS3427A) for free flow. If

necessary, clean the bore of the pipe of the level switch.

2 Carefully do a check of the temperature of the fuel leakage pipe (002, Figure 10-2) of

each fuel pump (001) to find the leakage pipe that has a fuel flow.

NOTE: There is a fuel flow in the leakage pipe that has a higher temperature than the

other leakage pipes.

3 Continue with Step 4 to find the location of the leakage at the related fuel pump and its

HP fuel pipes.

4 Do a check of the HP fuel pipe (005) at the highest inspection point (004) for leaks.

4.1 Carefully loosen the screw plug a maximum of two turns.

4.2 Do a check for fuel flow.

4.3 If there is fuel flow, repair the cause of the fuel flow as soon as possible, refer to

the Maintenance Manual 8752‑1.

NOTE: The fuel system has high pressure. Replace a defective HP fuel pipe

only when the engine has stopped and the pressure in the system is

released.

4.4 Tighten the screw plug.

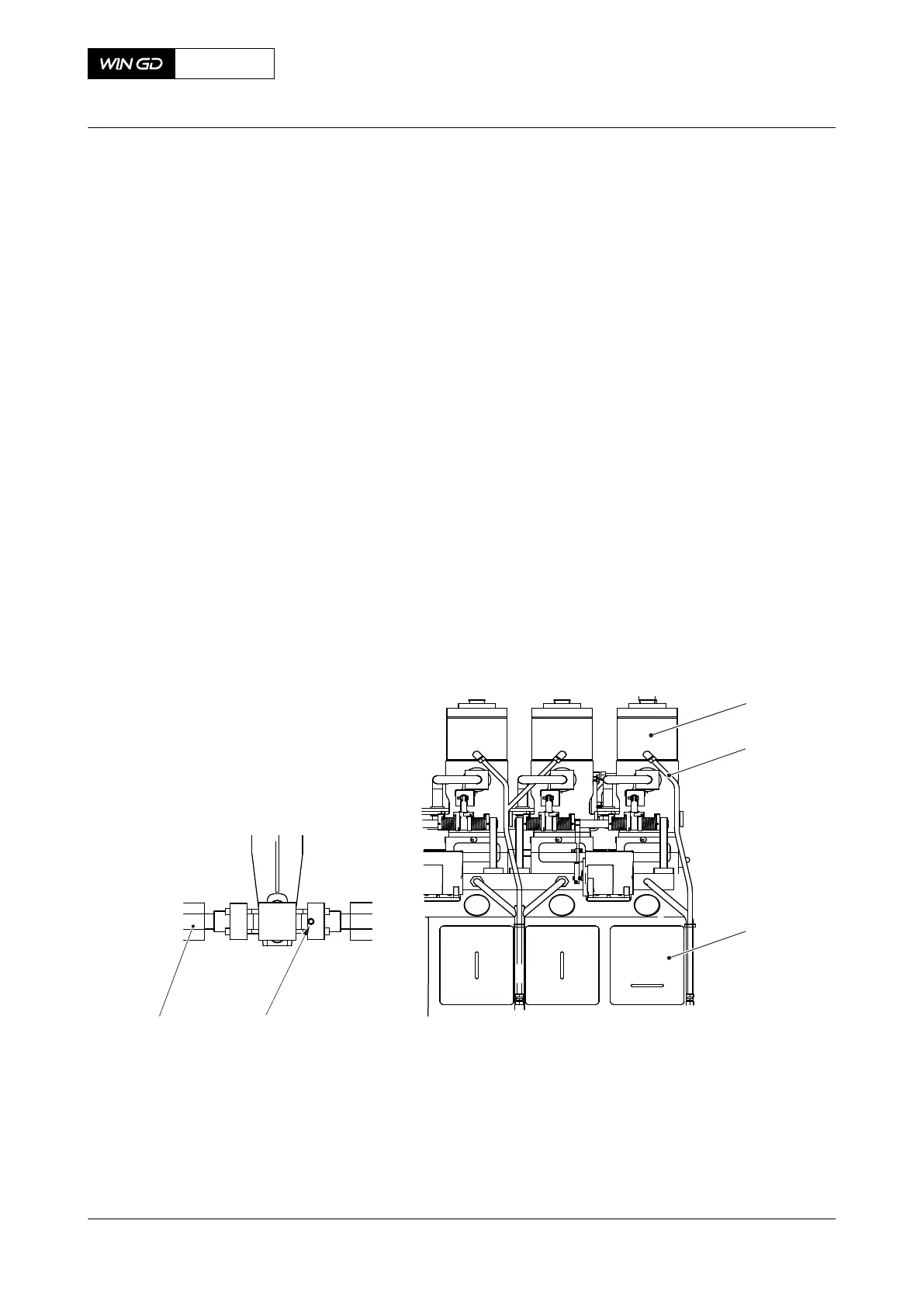

Fig 10-2 Supply unit (example) and example of inspection point

Legend

001 Fuel pump 004 Inspection point

002 Fuel leakage pipe 005 HP fuel pipe

003 Supply unit

X92DF

AA00-0000-00AAA-311B-A

Operation Manual Examine the supply unit for fuel leakage

Winterthur Gas & Diesel Ltd.

- 537 - Issue 002 2020-08

Loading...

Loading...