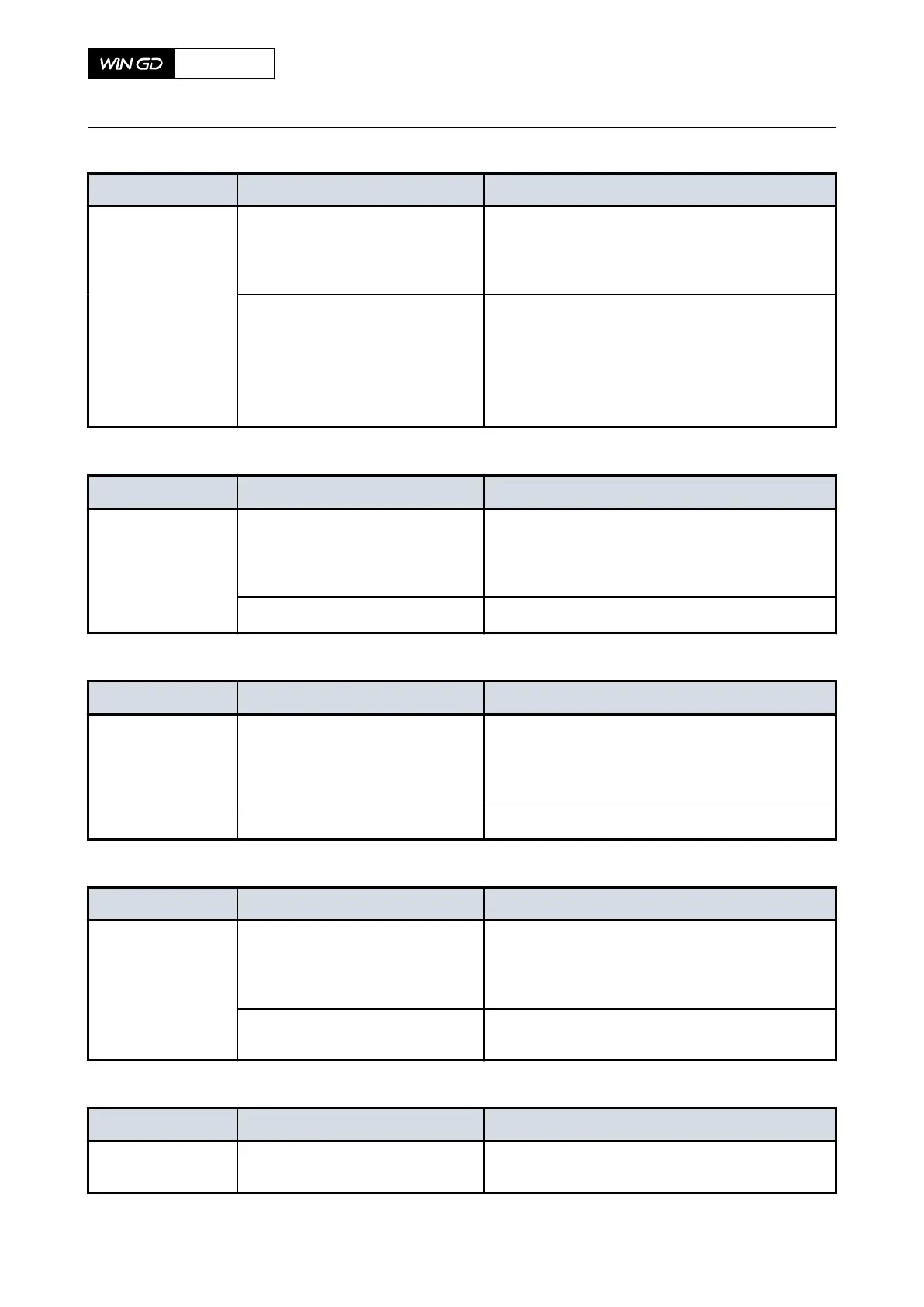

Tab 10-16 Piston cooling oil temperature downstream of a piston is too high

Indication Possible cause Procedure

TE2501-nnA This is a result of the malfunction

in Table 10-9 - Lubricating oil sup-

ply temperature at the engine inlet

is too high

•

Do the repair shown there.

A piston ring is defective

•

As a temporary procedure, cut out the in-

jection of the related cylinder.

•

As a temporary procedure, increase the

feed rate of the cylinder oil of the related

cylinder.

•

Repair or replace the piston rings.

Tab 10-17 Piston cooling oil flow to a piston is not in the permitted range

Indication Possible cause Procedure

FS2521-nnA This is a result of the malfunction

in Table 10-7 - Lubricating oil sup-

ply pressure at the engine inlet is

too low

•

Do the repair shown there.

A lever is defective

•

Repair the defective lever.

Tab 10-18 TC bearing oil temperature at a turbocharger outlet is too high

Indication Possible cause Procedure

TE2601-nnA This is a result of the malfunction

in Table 10-9 - Lubricating oil sup-

ply temperature at the engine inlet

is too high

•

Do the repair shown there.

A turbocharger is defective

•

Refer to the turbocharger manual.

Tab 10-19 TC bearing oil supply pressure upstream of a turbocharger is too low

Indication Possible cause Procedure

PT2611-nnA This is a result of the malfunction

in Table 10-7 - Lubricating oil sup-

ply pressure at the engine inlet is

too low

•

Do the repair shown there.

There is an incorrect setting of the

adjustable orifice

•

Set the adjustable orifice to the correct val-

ue.

Tab 10-20 TC bearing oil temperature at a turbocharger inlet is too high (external oil supply)

Indication Possible cause Procedure

TE2621A The external oil supply system is

defective

•

Find the cause and repair the fault.

X92DF

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 519 - Issue 002 2020-08

Loading...

Loading...