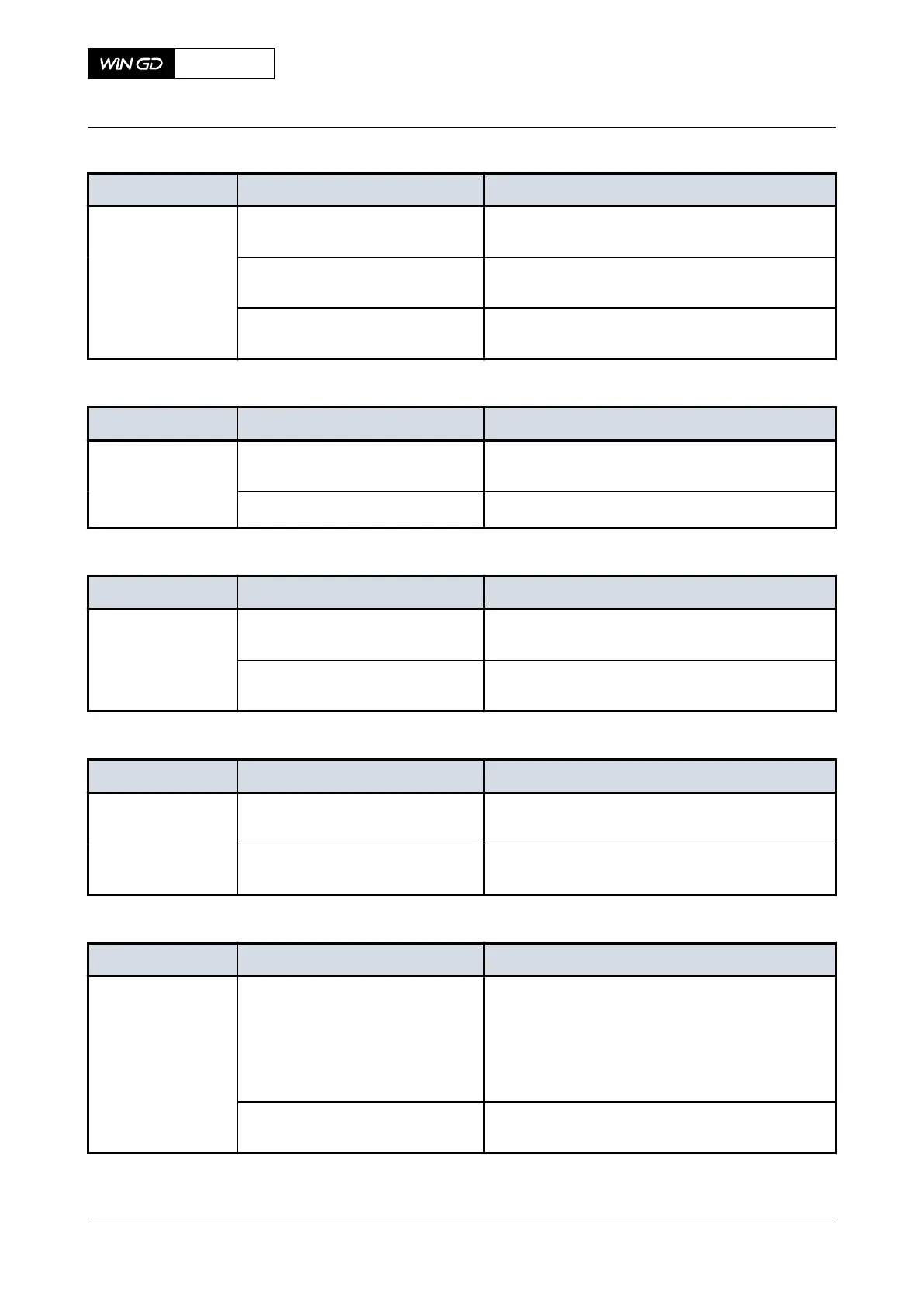

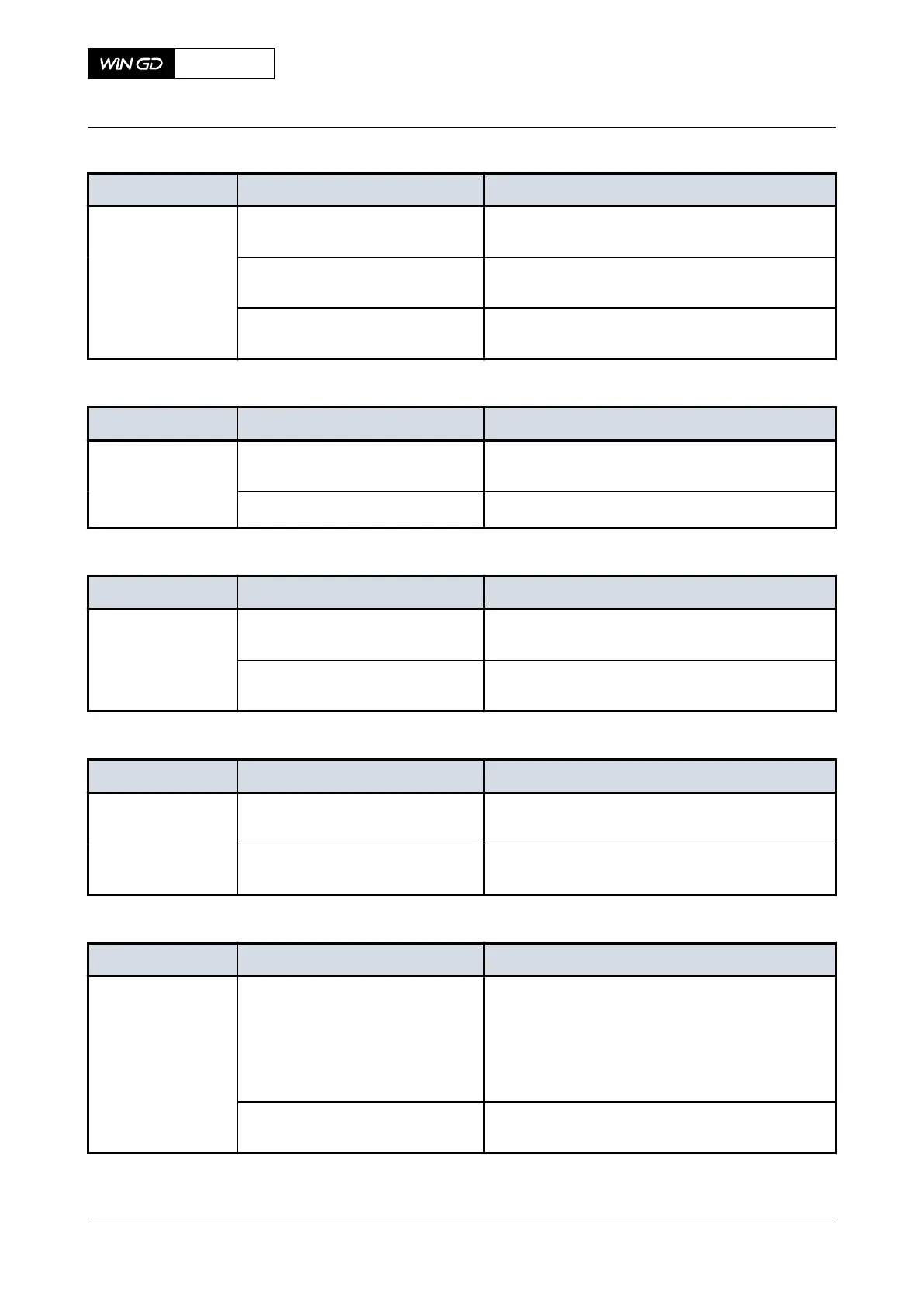

Tab 10-52 Pressure of the air spring air supply is too low

Indication Possible cause Procedure

PT4341A There is an incorrect setting of the

control air supply

•

Set the control air supply to the correct val-

ue.

There is an incorrect setting of the

safety valve

•

Set the safety valve to the correct value.

The control air supply is defective

•

Repair or replace the defective item of the

control air supply.

Tab 10-53 Oil leakage flow in the collector for leakage oil from the air spring is too high

Indication Possible cause Procedure

LS4351-52A The collector for leakage oil from

the air spring is clogged

•

Clean the collector for leakage oil from the

air spring.

The float control is defective

•

Repair the float control.

Tab 10-54 Control air supply pressure is too low (usual supply)

Indication Possible cause Procedure

PT4401A The control air supply system is

defective

•

Find the cause and repair the fault.

There is an incorrect setting of the

control air supply

•

Set the control air supply to the correct val-

ue.

Tab 10-55 Control air supply pressure is too low (stand-by supply)

Indication Possible cause Procedure

PT4411A The starting air supply system is

defective

•

Find the cause and repair the fault.

There is an incorrect setting of the

control air supply

•

Set the control air supply to the correct val-

ue.

Tab 10-56 Control air supply pressure is too low (safety supply)

Indication Possible cause Procedure

PT4421A This is a result of the malfunction

in Table 10-54 - Control air supply

pressure is too low (usual supply)

and in Table 10-55 - Control air

supply pressure is too low (stand-

by supply)

•

As a temporary procedure, stop the en-

gine.

•

Do the repair shown there.

The drain valve of the air tank is

open

•

Close the drain valve of the air tank.

X92DF

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 528 - Issue 002 2020-08

Loading...

Loading...