10.2.6 Malfunctions of the exhaust gas system (XX37NN)

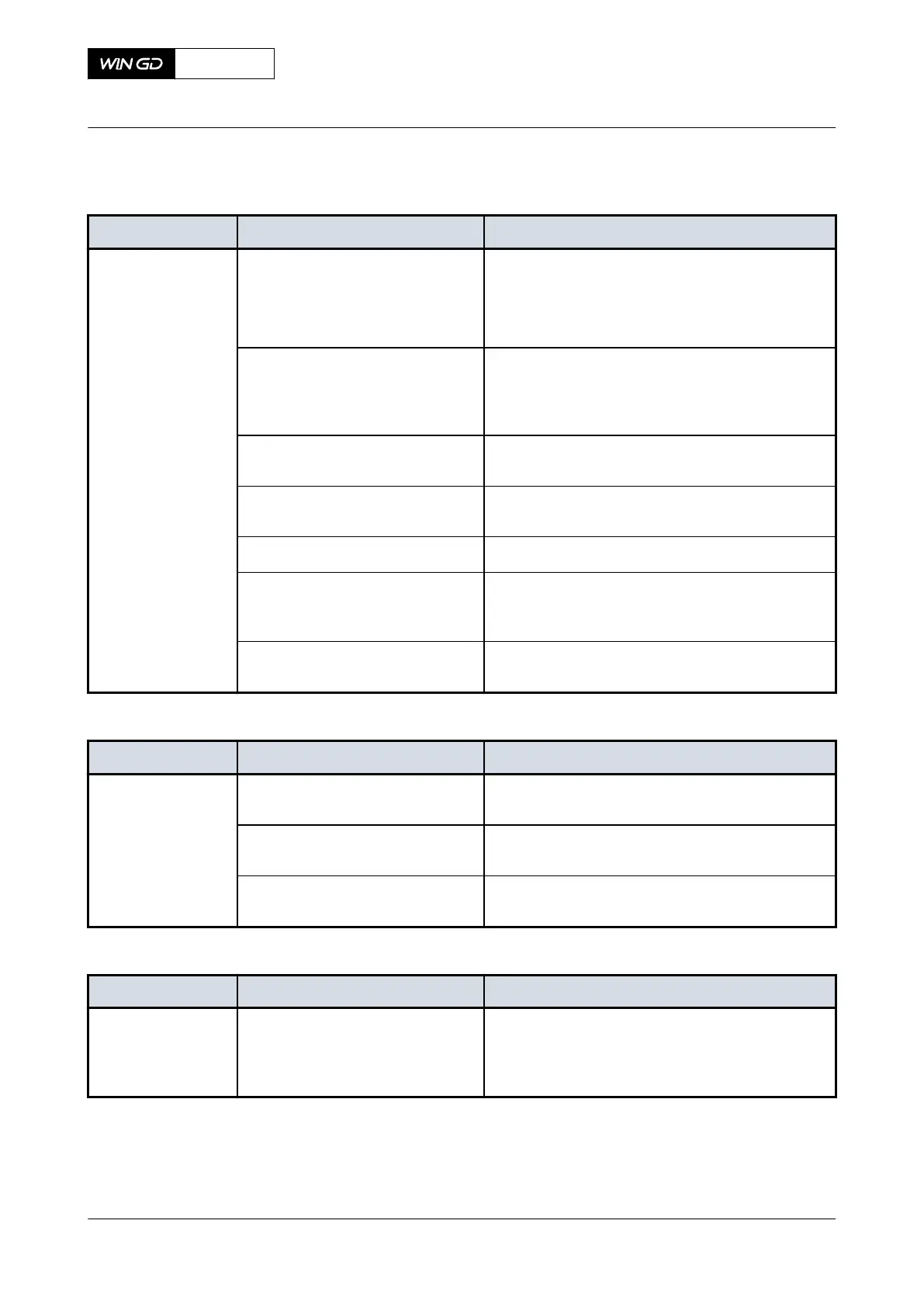

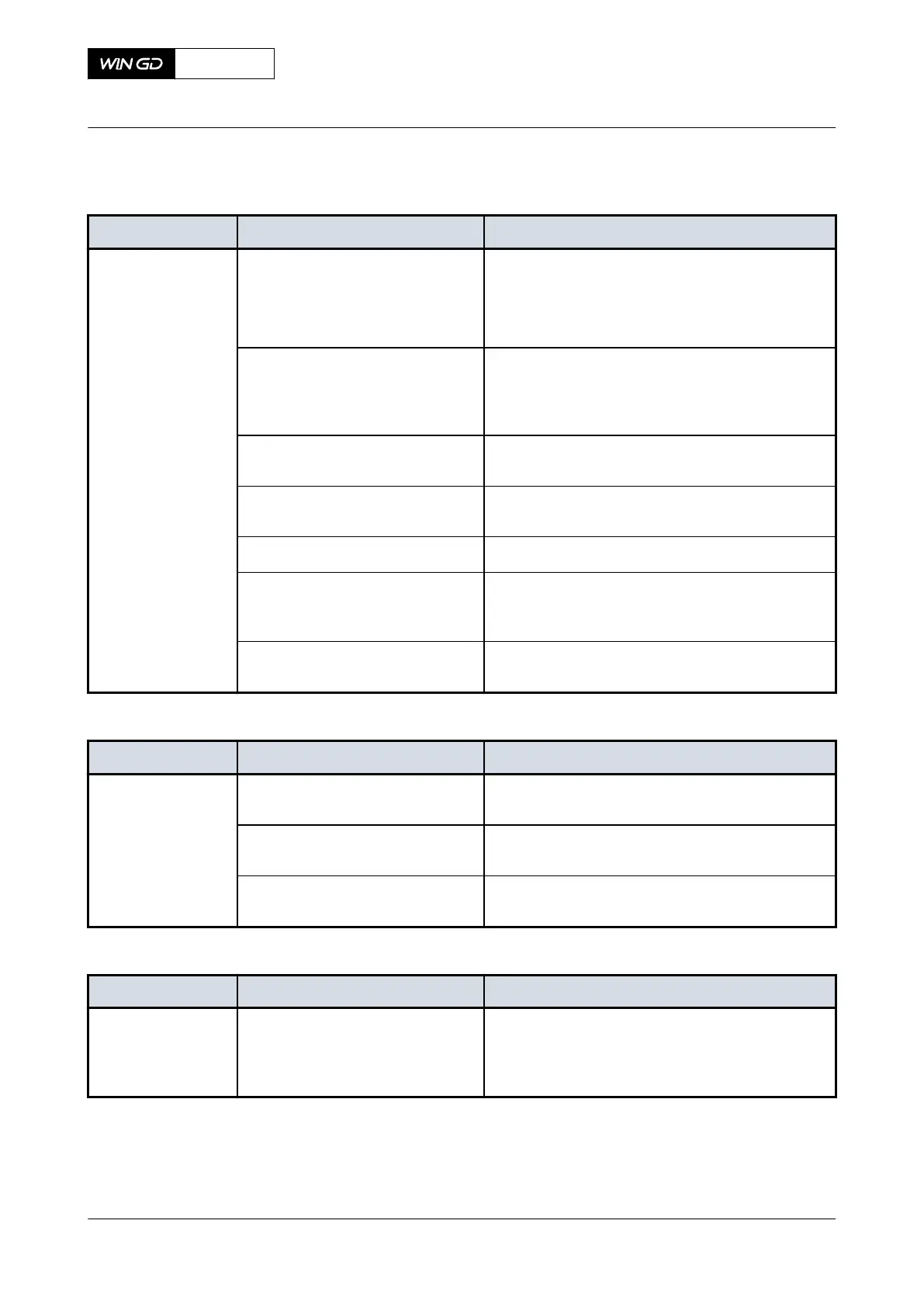

Tab 10-37 Exhaust gas temperature downstream of a cylinder is too high

Indication Possible cause Procedure

TE3701-nnA The scavenge air flow is too low

•

Clean the turbocharger.

•

Clean the air flaps in the scavenge air re-

ceiver.

•

Clean the scavenge ports.

This is a result of the malfunction

in Table 10-3 - Cylinder cooling

water temperature downstream of

a cylinder is too high

•

Do the repair shown there.

There is air in the cooling water

system

•

Open the vent valves of the cooling water

system.

An injection nozzle is defective

•

Repair or replace the defective injection

nozzle.

The injection time is too long

•

Find the cause and repair the fault.

There are leaks in the cooling wa-

ter system (for example cracks in

a cylinder liner)

•

Find the cause and repair the fault.

There is a fire in the piston under-

side

•

Do the procedure in section 2.4 Fire-fight-

ing in the scavenge air space.

Tab 10-38 Exhaust gas temperature difference downstream of all cylinders is too high

Indication Possible cause Procedure

TE3701-nnA An injection nozzle is defective

•

Repair or replace the defective injection

nozzle.

The fuel supply system is defec-

tive

•

Find the cause and repair the fault.

An exhaust valve is defective

•

Repair or replace the defective exhaust

valve.

Tab 10-39 Exhaust gas temperature upstream of a turbocharger is too high

Indication Possible cause Procedure

TE3721-nnA This is a result of the malfunction

in Table 10-37 - Exhaust gas tem-

perature downstream of a cylinder

is too high

•

Do the repair shown there.

X92DF

AA00-0000-00AAA-410C-A

Operation Manual Malfunctions of systems and components

Winterthur Gas & Diesel Ltd.

- 524 - Issue 002 2020-08

Loading...

Loading...