1/05

10-138

DocuColor 12/DCCS50

Functional Description of Fuser Subassemblies

Reissue

Principles of Operation

Copy Transport and Sensors

The unfused print is transported from the IBT Belt to the Fuser by the Vacuum Belt. A Fuser

Entrance Sensor just before the Vacuum Transport Assembly is used to detect paper jams from

the IBT by sensing the lead edge and trail edge of the copy. The lead edge of the copy is

guided into the Contact Arc of the Fuser by the Inlet Chute.

Stripper Fingers on the Pressure Roller and Heat

Roller help prevent t

he copy from wrapping

around these Rollers. As the copy leaves the Fuser nip, the lead edge enters the nip of the

Fuser Exit Rollers. A Fuser Exit Sensor detects the lead edge of the copy as it leaves the Fuser

Exit Rollers. This sensor looks for the lead edge of the copy as it exits the Fuser. If the lead

edge is more than 20 ms late to this sensor, the Fuser will stop, the Fuser nip will open and a

jam error code will be generated. The quick stopping of the Fuser helps prevent the copy from

getting wrapped around the Heat or Pressure Rolls. Copy jams of this type can always be

cleared from the Fuser entrance area.

Refer to Standby Power, Section 1 for information on machine safety interlocks.

Temperature Control and Power Usage

The Fuser Assembly includes three heated rollers. Each of these rollers have Tungsten Halo-

gen Quartz Lamps in their centers, and the heat generated by the lamp migrates to the surface

of th

e roller for the fusing process.

Fuser temperature control is complicated and as shown in Figu

re 3. there are four classes of

required components:

1. Thermistors to measure the temperature of each Fuser roll.

2. Lamps to heat the rolls

3. Control hardware and software to read the temperature and switch the lamps on and off.

4. Thermostats to prevent the Fuser from catastrophically overheating due to a component

failure.

To

monitor and regulate the Fuser heating cycles, each roll has two thermistors (Table 3) and a

ther

mostat on or near the external surfaces of the rolls. The functions of each are as follows:

• Control Thermistors - Th

ese determine the nominal set and run temperatures of the

associated roll. The current through these devices is monitored by the IOT Drive and Con-

trol PWBAs. These are in direct contact with each roll.

• O

verheat Thermistors - These a

re also monitored by the IOT Drive and Control PWBAs.

When the current through one of these devices reaches a particular value, the IOT Con-

trol and Drive PWBAs attempt to completely shut off the heater for the associated roll.

T

hi

s occurs when the thermistors sense a temperature of 230° C or more. These Ther-

mistors are in direct contact with each roll.

• O

verheat Thermostats - Th

ese are Fail-Safe switches. When a Thermostat senses an

overheat condition (>230° C), it opens and disconnects power from the associated heat

lamp. the Thermostats are spaced approximately 3 mm from the surface of each Roll.

These thermostats cannot be reset.

• The Heat Ro

ll

(HR) is 65mm in diameter, with a 4.5mm aluminum thick wall and 3mm Sil-

icon Rubber base coating and a layer of Viton on the outs

ide. The Heat Roll has priority

over the other two rolls for power required for the heat lamp. The Heat Roll has its own

drive motor for copy transport.

• The P

ressure Ro

ll (PR) is 65mm in diameter, with a 4.5mm aluminum thick wall and a

2mm Silicon Rubber base coating and a layer of Viton on the outside. The Pressure Roll

is mounted on brackets, which cam up to the bottom of the Heat Roll to create the Fuser

Contact Arc. The Pressure Roll is gear driven by the Fuser Motor.

• The E

xternal Heat Roll (EHR)

is a 23mm diameter stainless steel roll with a 2.5mm thick

wall. Its purpose is to help regulate the surface temperature of the Heat Roll by applying

additional heat directly to the surface of the Heat Roll. This reduces variations in tempera-

ture of the Heat Roll surface. The External Heat Roll rotation comes from direct contact

wit

h the

motor driven Heat Roll.

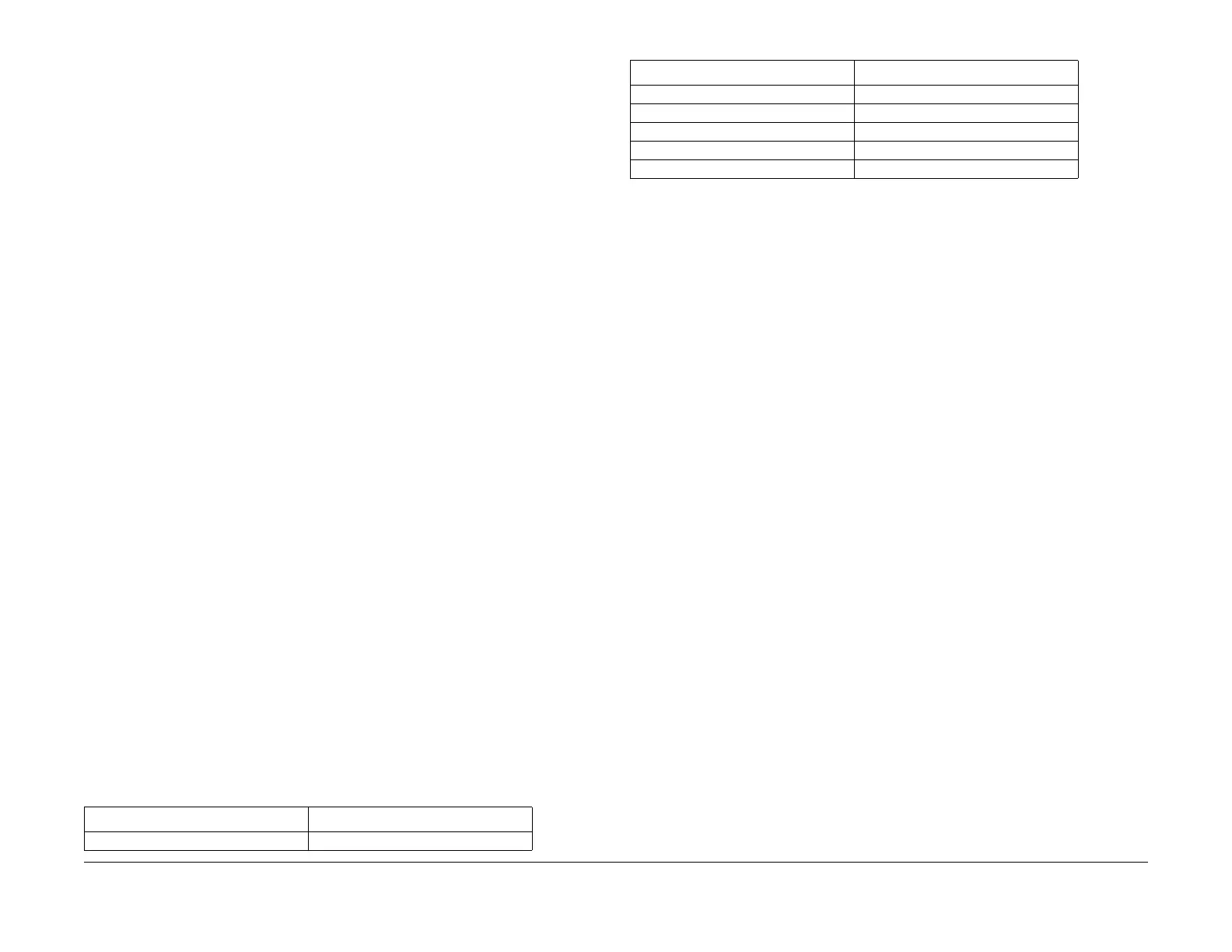

Table 3 Fuser Thermistor Resistance Values

Thermistor Temperature (°C) Thermistor Resistance (kOhms)

20 102 - 150

50 10 - 40

100 5.7 - 6.9

130 2.46 - 2.95

160 1.22 - 1.35

180 0.78 - 0.87

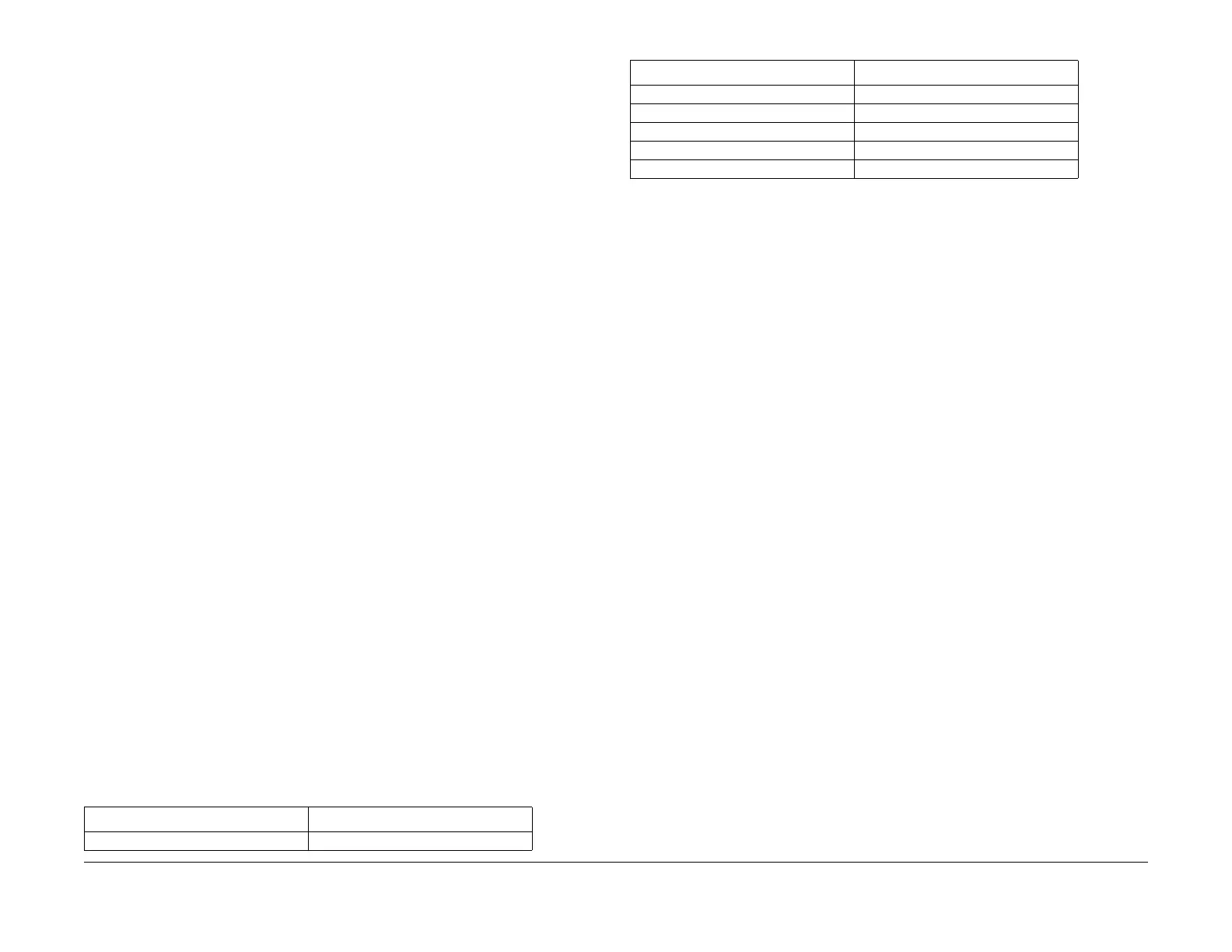

Table 3 Fuser Thermistor Resistance Values

T

hermi

stor Temperature (°C) Thermistor Resistance (kOhms)

manuals4you.commanuals4you.com

Loading...

Loading...