PERIODIC MAINTENANCE

3-5

2. Remove:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

3. Remove:

• Air filter case

Refer to “AIR FILTER CASE” on page 7-

5.

4. Disconnect:

• Ignition coil

5. Remove:

• Spark plug

ECA13320

Before removing the spark plugs, blow

away any dirt accumulated in the spark

plug wells with compressed air to prevent it

from falling into the cylinders.

6. Check:

• Spark plug type

Incorrect → Change.

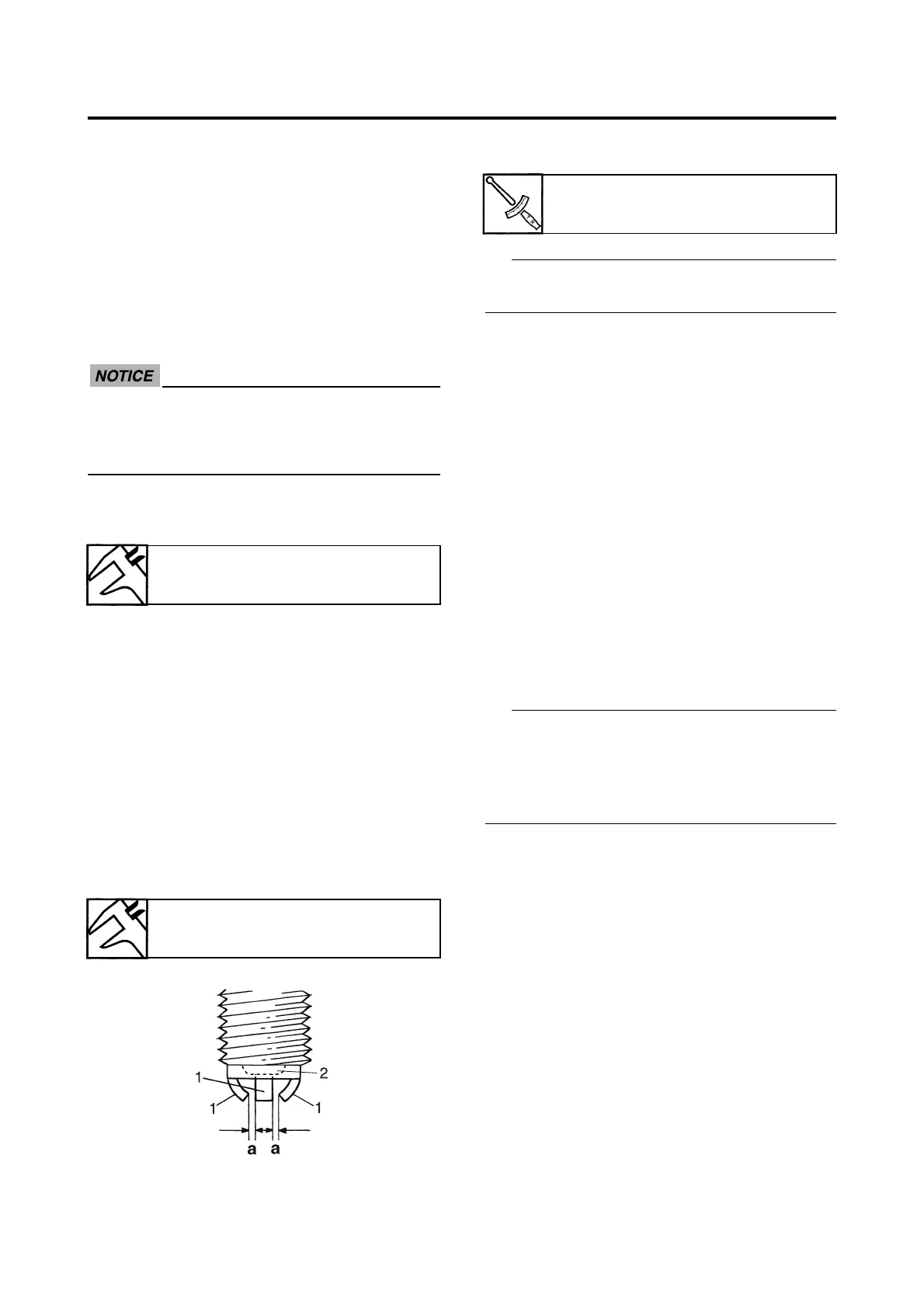

7. Check:

• Electrode “1”

Damage/wear → Replace the spark plug.

• Insulator “2”

Abnormal color → Replace the spark

plug.

Normal color is medium-to-light tan.

8. Clean:

• Spark plug

(with a spark plug cleaner or wire brush)

9. Measure:

• Spark plug gap “a”

(with a wire thickness gauge)

Out of specification → Regap.

10. Install:

• Spark plug

Before installing the spark plug, clean the

spark plug and gasket surface.

11. Install:

• Ignition coil

12. Install:

• Air filter case

Refer to “AIR FILTER CASE” on page 7-

5.

13. Install:

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

14. Install:

• Lower cowlings

• Side cowlings

Refer to “GENERAL CHASSIS” on page

4-1.

EAS20490

ADJUSTING THE VALVE CLEARANCE

The following procedure applies to all of the

valves.

• Valve clearance adjustment should be made

on a cold engine, at room temperature.

• When the valve clearance is to be measured

or adjusted, the piston must be at top dead

center (TDC) on the compression stroke.

1. Remove:

• Rider seat

Refer to “GENERAL CHASSIS” on page

4-1.

• Fuel tank

Refer to “FUEL TANK” on page 7-1.

• Air filter case

Refer to “AIR FILTER CASE” on page 7-

5.

• Lower cowlings

• Side cowlings

Refer to “GENERAL CHASSIS” on page

4-1.

• Throttle body assembly

Refer to “THROTTLE BODIES” on page

7-12.

Manufacturer/model

NGK/LMAR9E-J

Spark plug gap

0.6–0.7 mm (0.024–0.028 in)

Spark plug

13 Nm (1.3 m·kgf, 9.4 ft·lbf)

Loading...

Loading...