CONNECTING RODS AND PISTONS

5-82

EAS26190

INSTALLING THE CONNECTING ROD AND

PISTON

The following procedure applies to all of the

connecting rods and pistons.

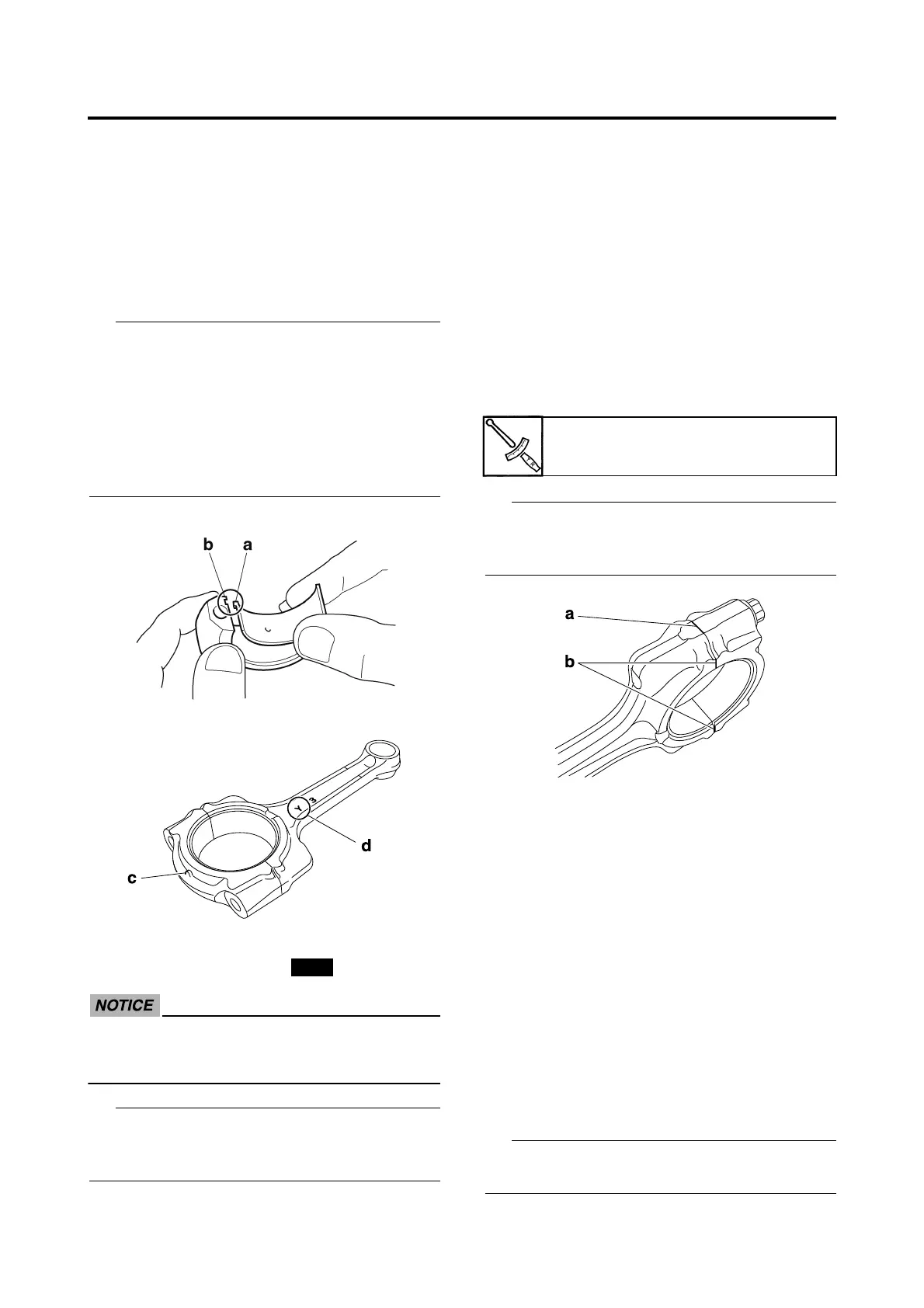

1. Install:

• Big end bearings

• Connecting rod cap

(onto the connecting rod)

• Be sure to reinstall each big end bearing in

its original place.

• Align the projections “a” on the big end bear-

ings with the notches “b” in the connecting

rods and connecting rod caps.

• Make sure that the projection “c” on the con-

necting rod cap faces the same direction as

the “Y” mark “d” on the connecting rod.

2. Tighten:

• Connecting rod bolts

ECA14B1042

Tighten the connecting rod bolts using the

plastic-region tightening angle method.

Always install new bolts.

Install by carrying out the following procedures

in order to assemble in the most suitable con-

dition.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Replace the connecting rod bolts with new

ones.

b. Clean the connecting rod bolts and lubri-

cate the bolt threads and seats with molyb-

denum disulfide oil.

c. After installing the big end bearing, assem-

ble the connecting rod and connecting rod

cap without installing them onto the crank-

shaft.

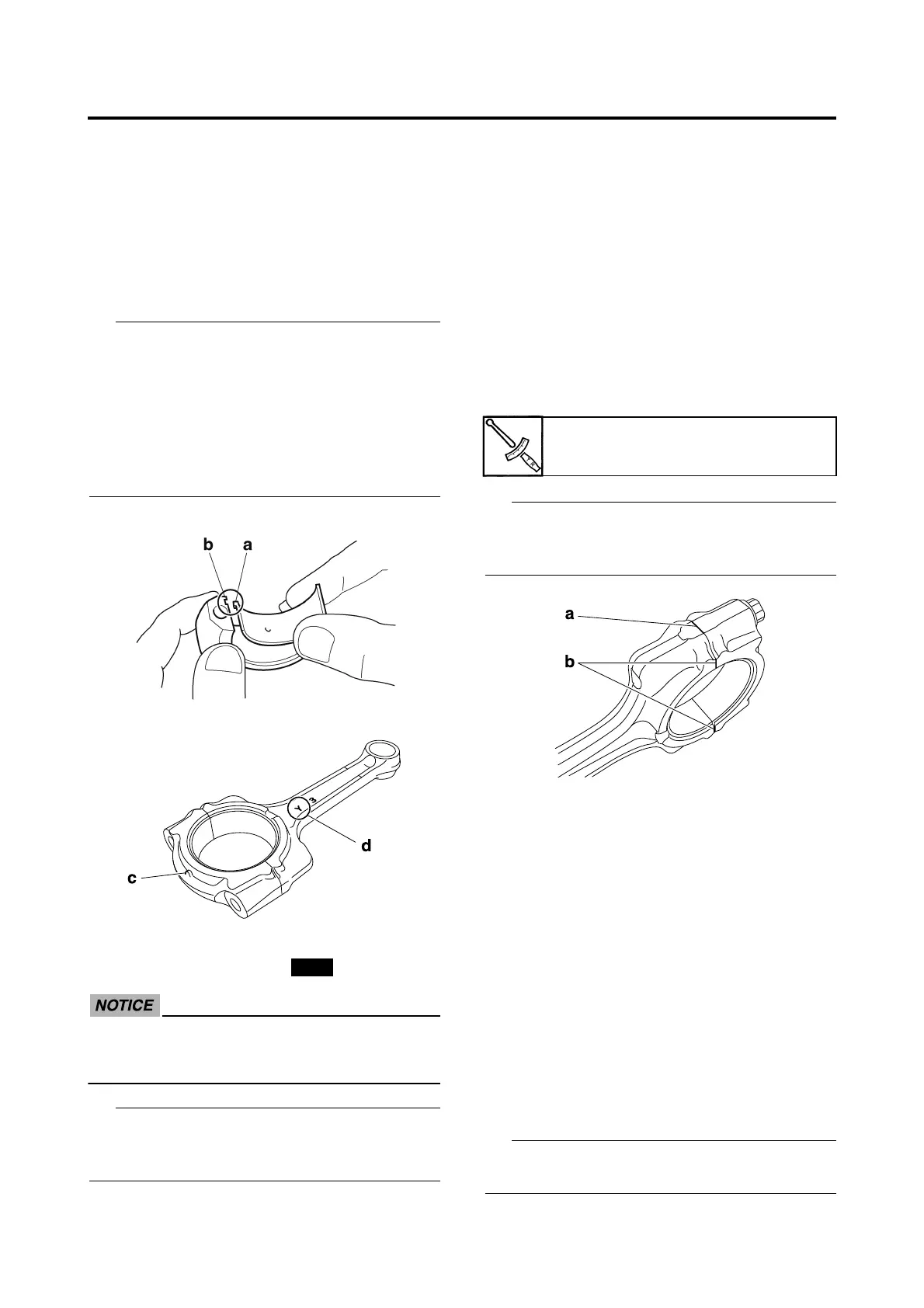

d. Tighten the connecting rod bolt while

checking that the sections shown “a” and

“b” are flush with each other by touching

the surface.

To install the big end bearing, care should be

taken not to install it at an angle and the posi-

tion should not be out of alignment.

e. Loosen the connecting rod bolt, remove the

connecting rod and connecting rod cap and

install these parts to the crankshaft with the

big end bearing kept in the current condi-

tion.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

3. Install:

• Oil ring expander “1”

• Lower oil ring rail “2”

• Upper oil ring rail “3”

• 2nd ring “4”

• Top ring “5”

(into the piston)

Be sure to install the piston rings so that the

manufacturer’s marks or numbers “a” face up.

Connecting rod bolt

30 Nm (3.0 m·kgf, 22 ft·lbf)

a. Side machined face

b. Thrusting faces

Loading...

Loading...