PERIODIC MAINTENANCE

3-22

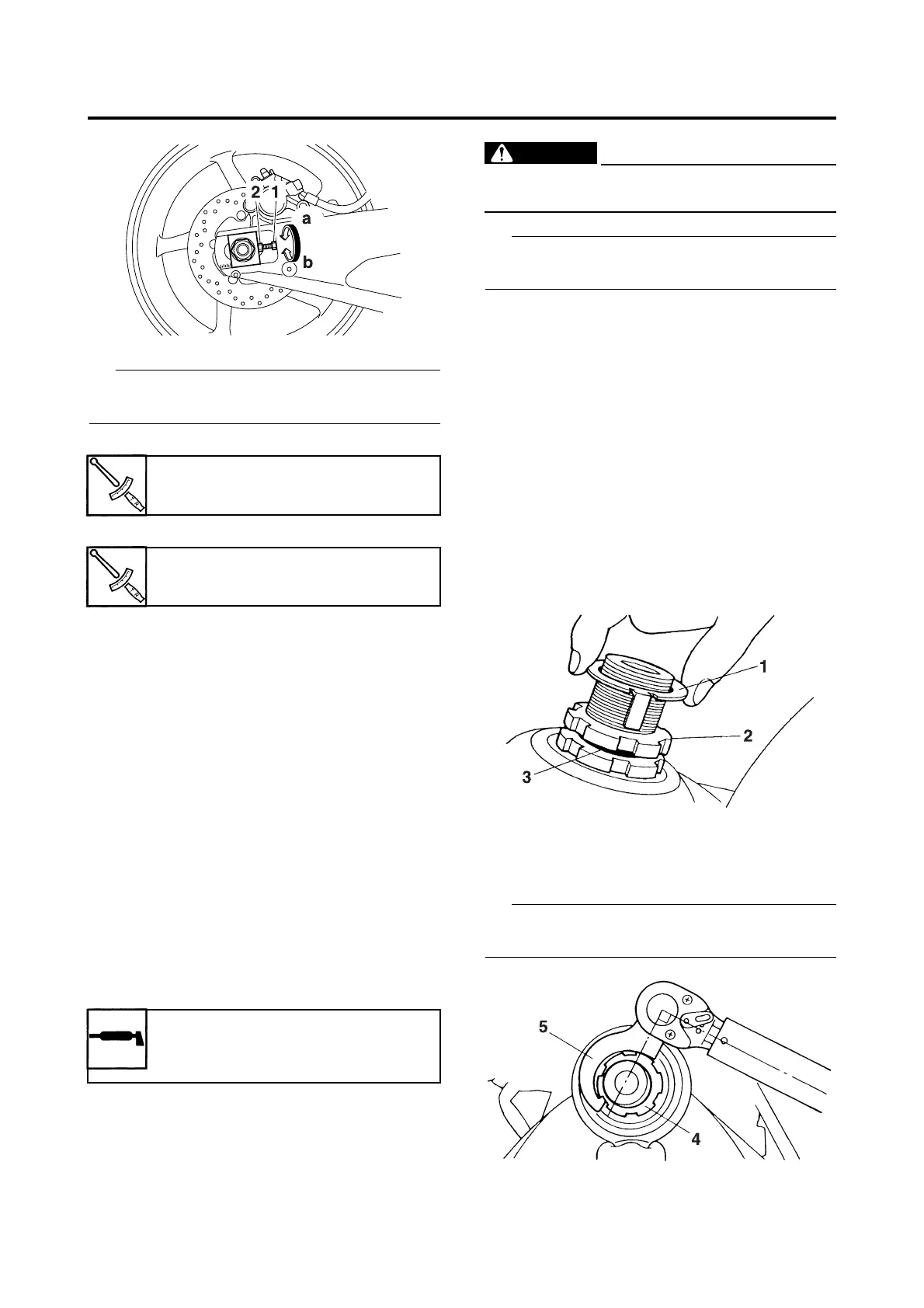

To maintain the proper wheel alignment, adjust

both sides evenly.

c. Tighten the wheel axle nut to specification.

d. Tighten the locknuts to specification.

▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲▲

EAS21440

LUBRICATING THE DRIVE CHAIN

The drive chain consists of many interacting

parts. If the drive chain is not maintained prop-

erly, it will wear out quickly. Therefore, the drive

chain should be serviced, especially when the

vehicle is used in dusty areas.

This vehicle has a drive chain with small rub-

ber O-rings between each side plate. Steam

cleaning, high-pressure washing, certain sol-

vents, and the use of a coarse brush can dam-

age these O-rings. Therefore, use only

kerosene to clean the drive chain. Wipe the

drive chain dry and thoroughly lubricate it with

engine oil or chain lubricant that is suitable for

O-ring chains. Do not use any other lubricants

on the drive chain since they may contain sol-

vents that could damage the O-rings.

EAS21500

CHECKING AND ADJUSTING THE STEER-

ING HEAD

1. Stand the vehicle on a level surface.

EWA13120

Securely support the vehicle so that there

is no danger of it falling over.

Place the vehicle on a suitable stand so that

the front wheel is elevated.

2. Check:

• Steering head

Grasp the bottom of the front fork legs

and gently rock the front fork.

Binding/looseness → Adjust the steering

head.

3. Remove:

• Upper bracket

Refer to “HANDLEBARS” on page 4-55

and “STEERING HEAD” on page 4-70.

4. Adjust:

• Steering head

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

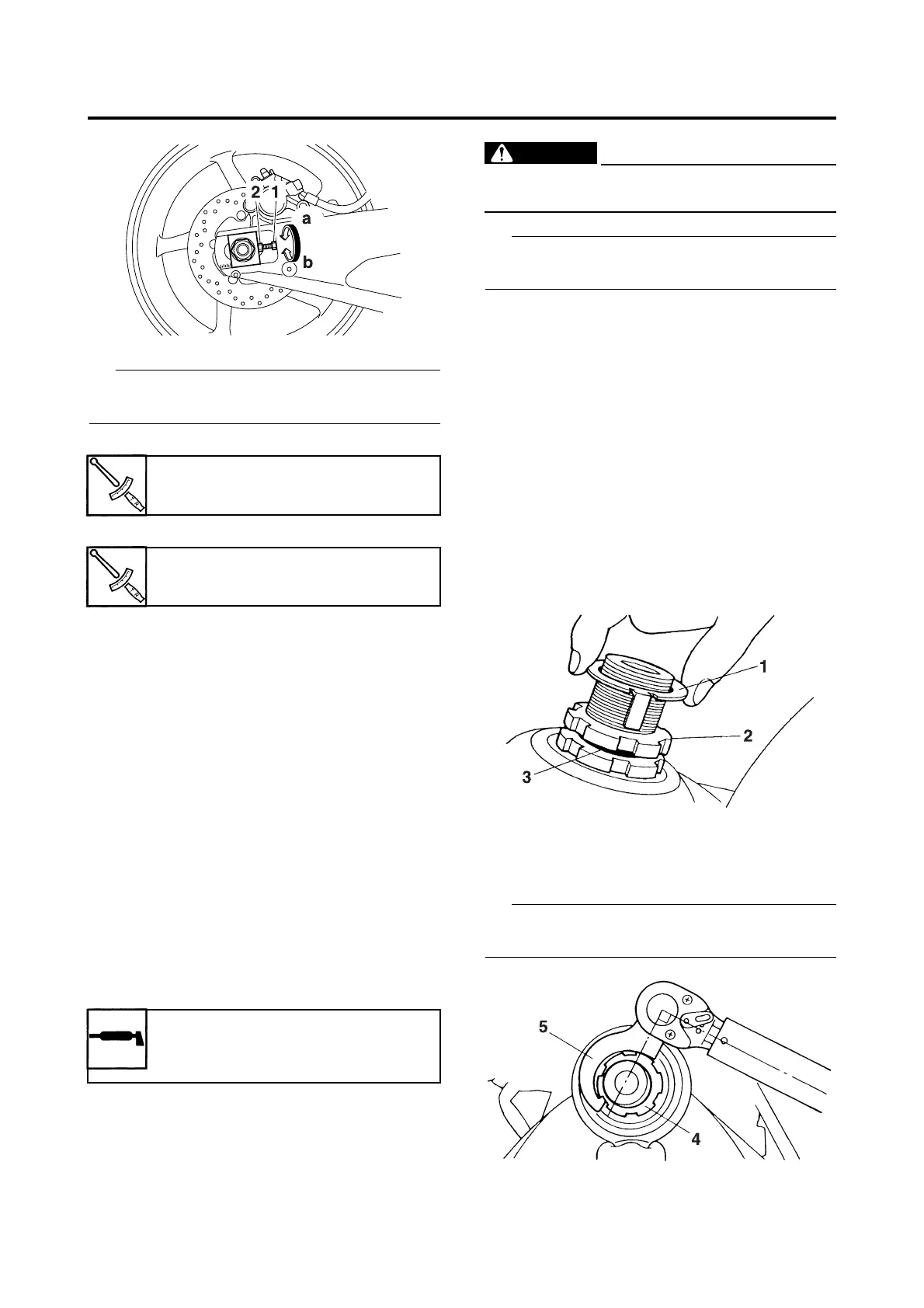

a. Remove the lock washer “1”, the upper ring

nut “2”, and the rubber washer “3”.

b. Loosen the lower ring nut “4” and then

tighten it to specification with a steering nut

wrench “5”.

Set the torque wrench at a right angle to the

steering nut wrench.

Wheel axle nut

150 Nm (15 m·kgf, 110 ft·lbf)

Locknut

16 Nm (1.6 m·kgf, 11 ft·lbf)

Recommended lubricant

Chain lubricant suitable for O-

ring chains

Loading...

Loading...