CRANKSHAFT

5-87

EAS25980

REMOVING THE CRANKSHAFT AND BAL-

ANCER SHAFT

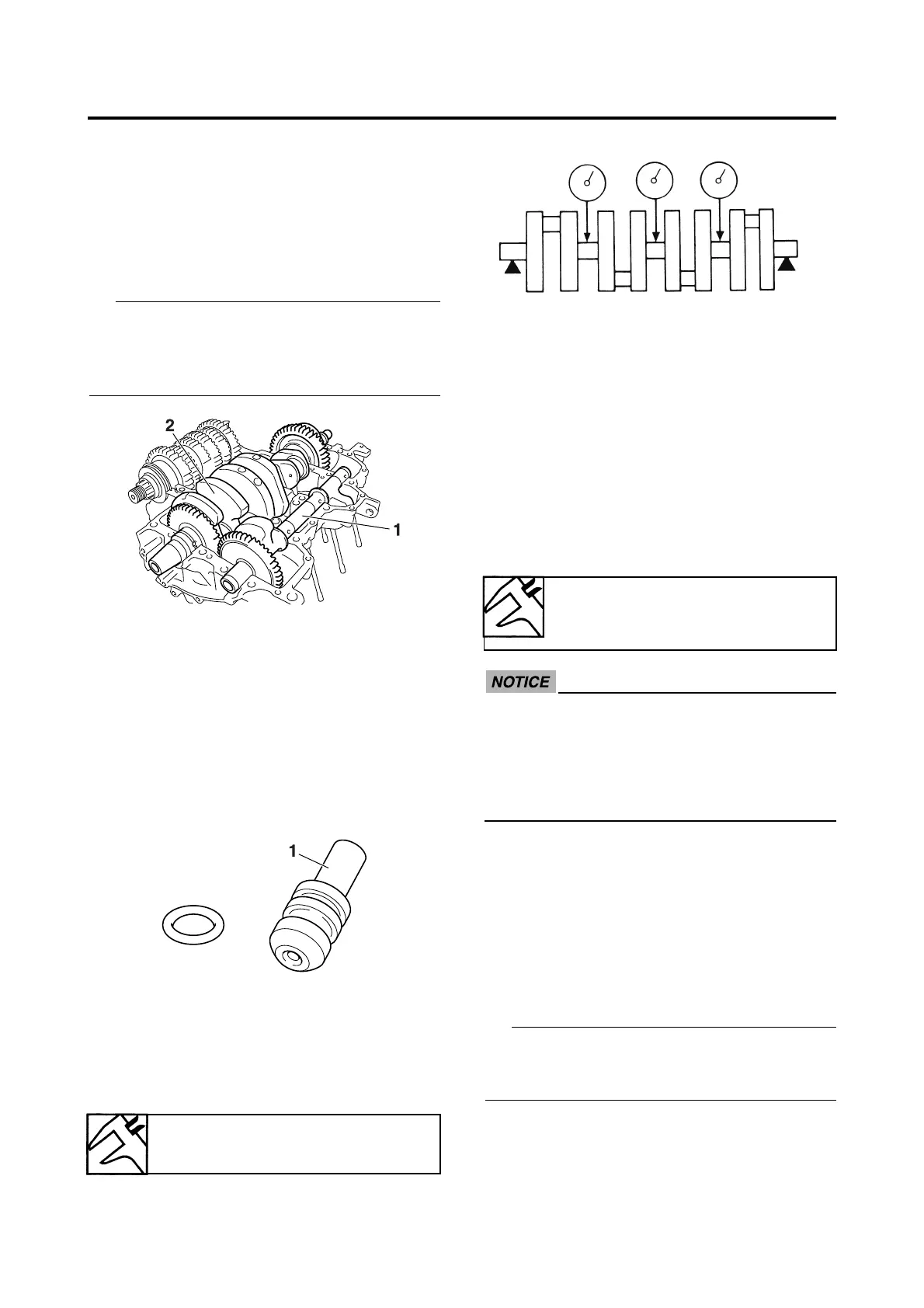

1. Remove:

• Balancer shaft “1”

• Balancer shaft journal bearings

• Crankshaft assembly “2”

• Crankshaft journal bearings

Identify the position of each balancer shaft

journal bearings and crankshaft journal bear-

ings so that it can be reinstalled in its original

place.

EAS14B1025

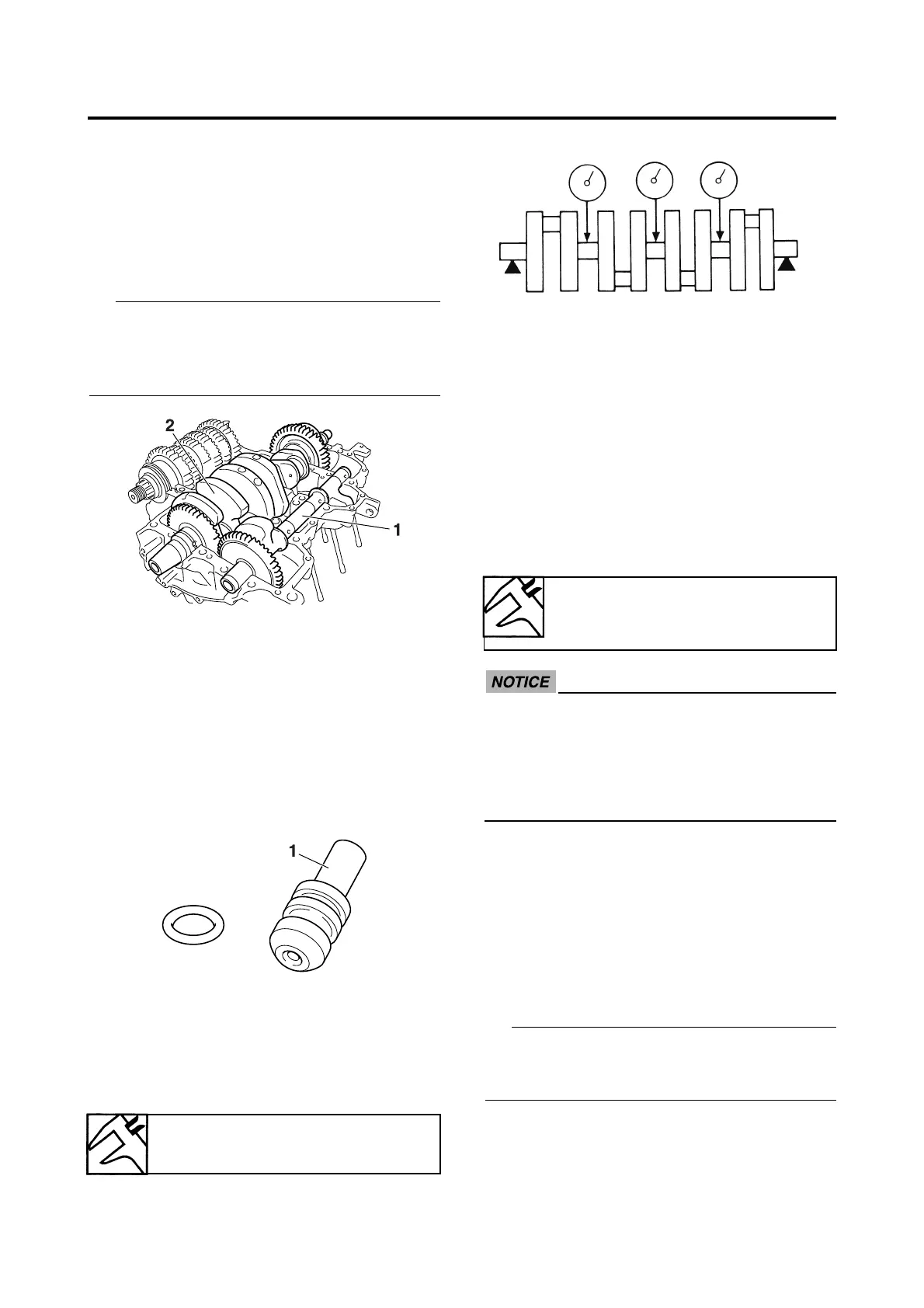

CHECKING THE OIL NOZZLES

The following procedure applies to all of the oil

nozzles.

1. Check:

• Oil nozzle “1”

Damage/wear → Replace the oil nozzle.

• Oil passage

Obstruction → Blow out with compressed

air.

EAS14B1026

CHECKING THE CRANKSHAFT

1. Measure:

• Crankshaft runout

Out of specification → Replace the crank-

shaft.

2. Check:

• Crankshaft journal surfaces

• Crankshaft pin surfaces

• Bearing surfaces

Scratches/wear → Replace the crank-

shaft.

3. Measure:

• Crankshaft-journal-to-crankshaft-journal-

bearing clearance

Out of specification → Replace the crank-

shaft journal bearings.

ECA13920

Do not interchange the crankshaft journal

bearings. To obtain the correct crankshaft-

journal-to-crankshaft-journal-bearing clear-

ance and prevent engine damage, the

crankshaft journal bearings must be

installed in their original positions.

▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼▼

a. Clean the crankshaft journal bearings,

crankshaft journals, and bearing portions of

the crankcase.

b. Place the upper crankcase upside down on

a bench.

c. Install the crankshaft journal upper bear-

ings “1” and the crankshaft into the upper

crankcase.

Align the projections “a” on the crankshaft jour-

nal upper bearings with the notches “b” in the

upper crankcase.

Crankshaft runout limit

0.030 mm (0.0012 in)

Journal oil clearance

0.004–0.039 mm (0.0002–

0.0015 in)

Loading...

Loading...