E11 4

2.4 Height adjustment for large working widths / with brace

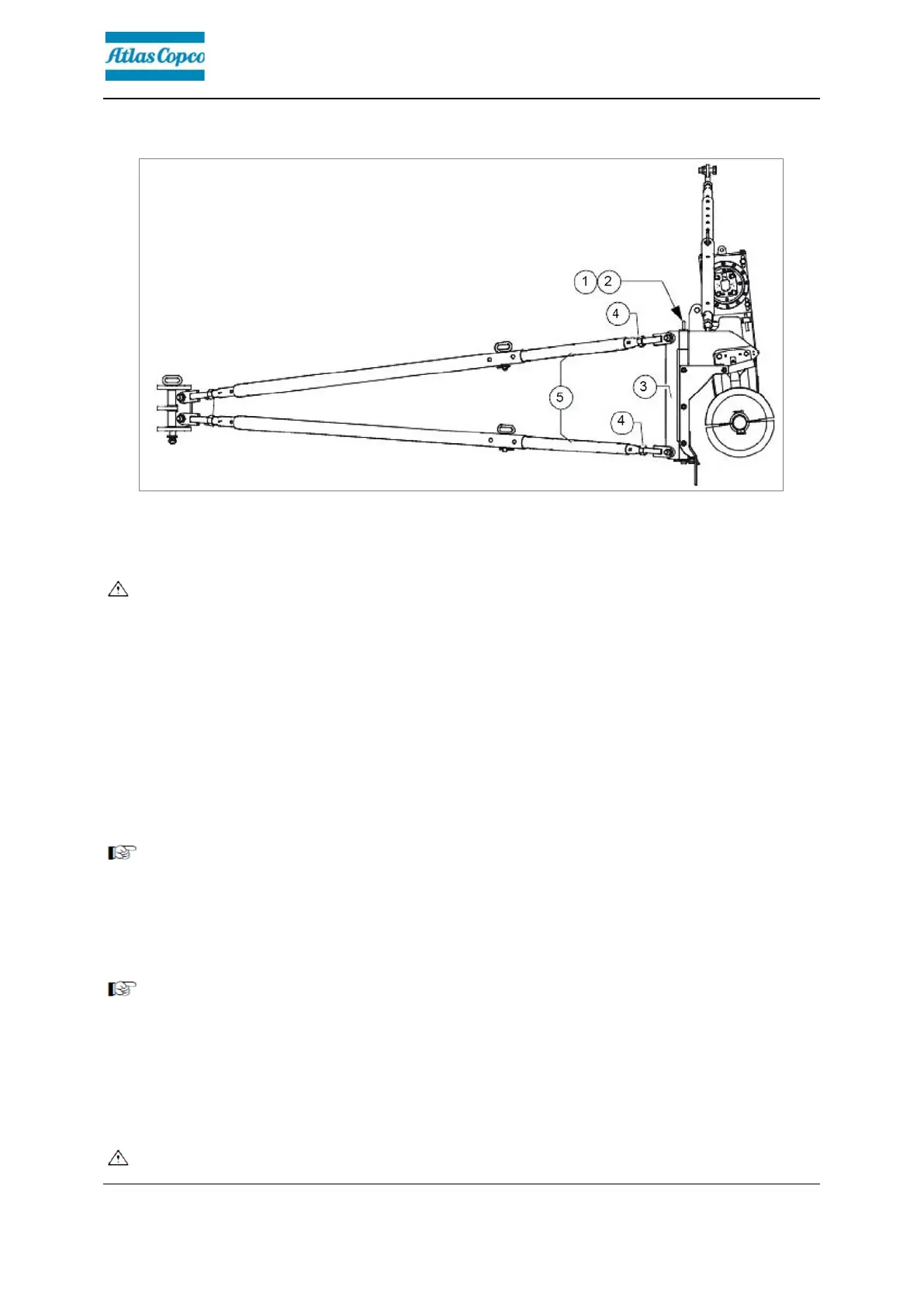

Auger height adjustment for large working widths can be carried out with a hinged

brace:

Only adjust the height of the auger with the slewing bracket retaining pins removed!

- Remove the split pin (1) on the slewing bracket (3) and keep the retaining pin (2)

on both sides of the vehicle.

- Push the slewing brackets with braces from the attaching point on the material

shaft.

- Carry out height adjustment.

- Push the slewing brackets with braces onto the attaching point on the material

shaft.

- Install the split pin (1) and retaining pin (2) again.

If the retaining pins (2) cannot be inserted in the new position, the braces must be

extended or shortened by rotating the adjustment rods until a continuous bore

enables the retaining pin (2) to be inserted.

- Loosen lock nuts (4).

The adjustment rods (5) are each equipped with a bore. A suitable drift can be

used to adjust the length of the adjustment rod here.

- Extend or shorten the braces by rotating the adjustment rods(5)until the retaining

pins can be inserted.

- Retighten the lock nuts (4).

- Install the split pin (1) and retaining pin (2).

Each time the height is adjusted, the auger must be realigned via the braces!

Loading...

Loading...