F31 3

1.2 Points of maintenance

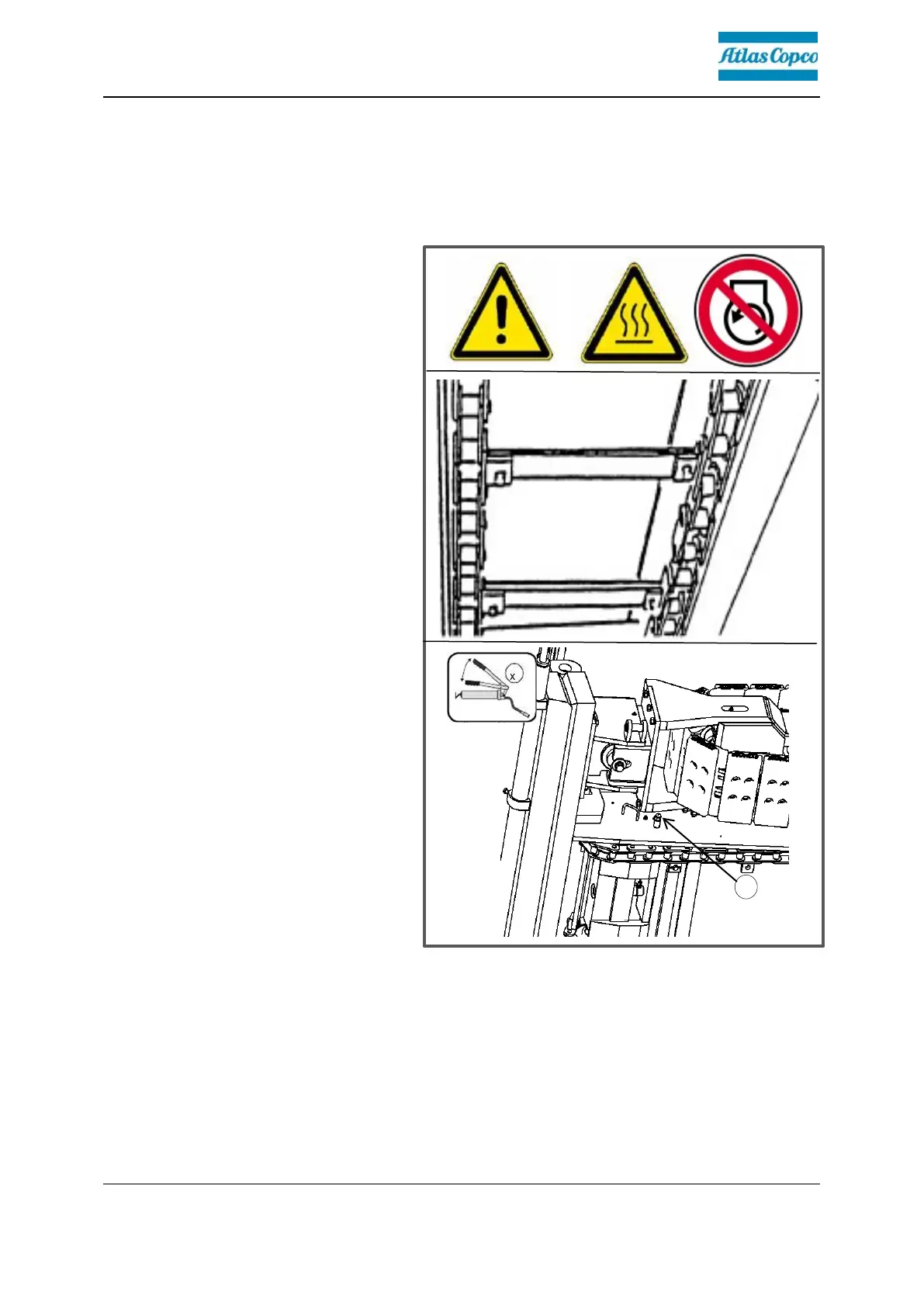

Chain tension, conveyor

The chain tension is to avoid chain

turning too slack after wearing while

working, therefore, chain can not

well-engaged and become

unapproached. Meanwhile, increase

the meshing angle between chain

and sprocket.

Visually check the chain tension

everyday, the lower edge of the

chain should not be over the lower

edge of the chassis. If exceeding

detected, please tighten the chain.

The conveyor chain should not be

too tight or too slack. An excessively

taut chain can cause the chain to be

stopped or to break when material

falls into the space between the

chain and the sprocket, therefore,

shorten the service life.

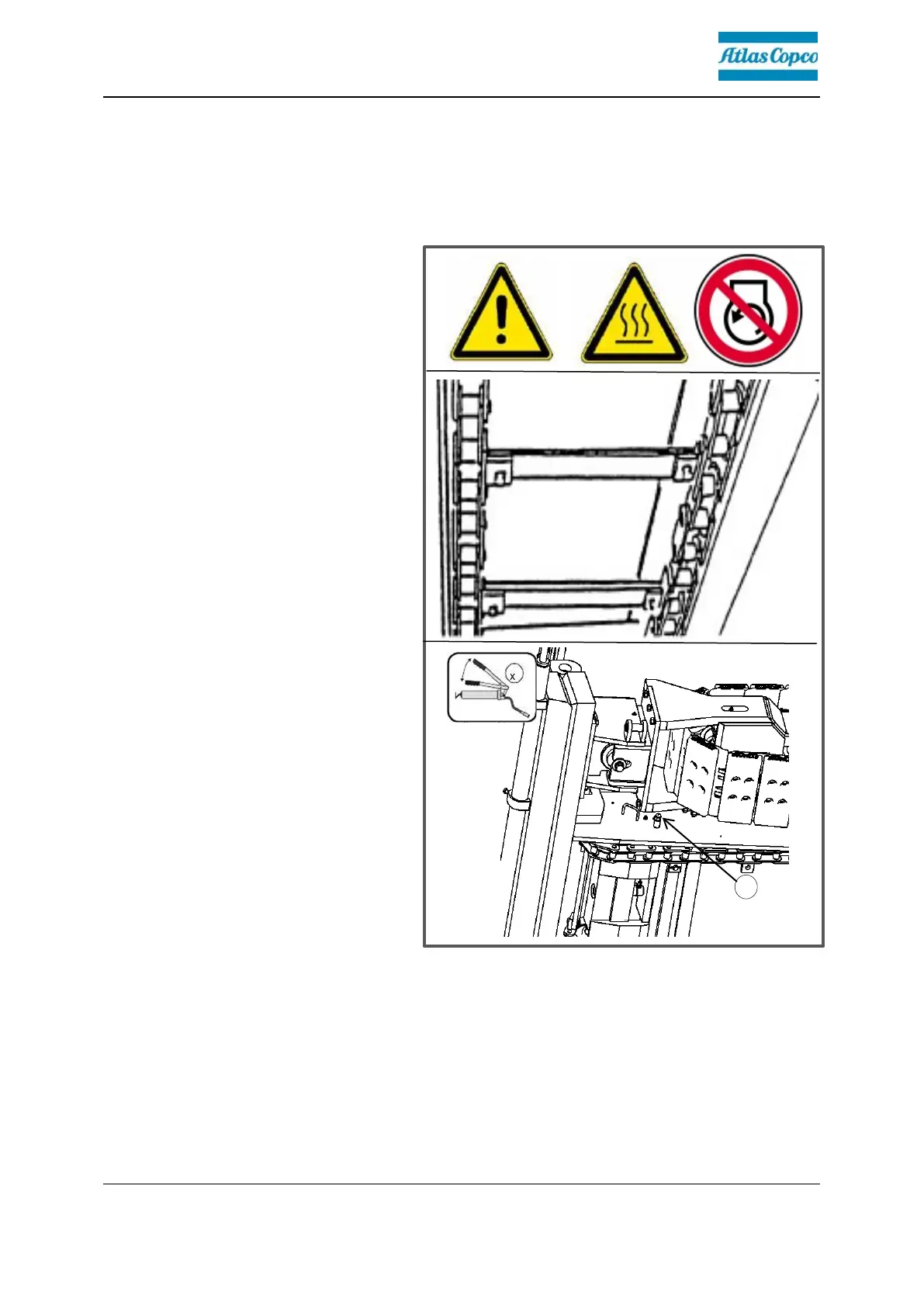

Adjustment of the chain tension:

Grease injection to tension the chain by using the grease gun. Put the grease gun to

filling connections (A), check the chain tension while filling the grease. Stop filling and

take off the grease gun when lower edge of the conveyor chain is at the lower edge of

the chassis level.

Loading...

Loading...