23.19

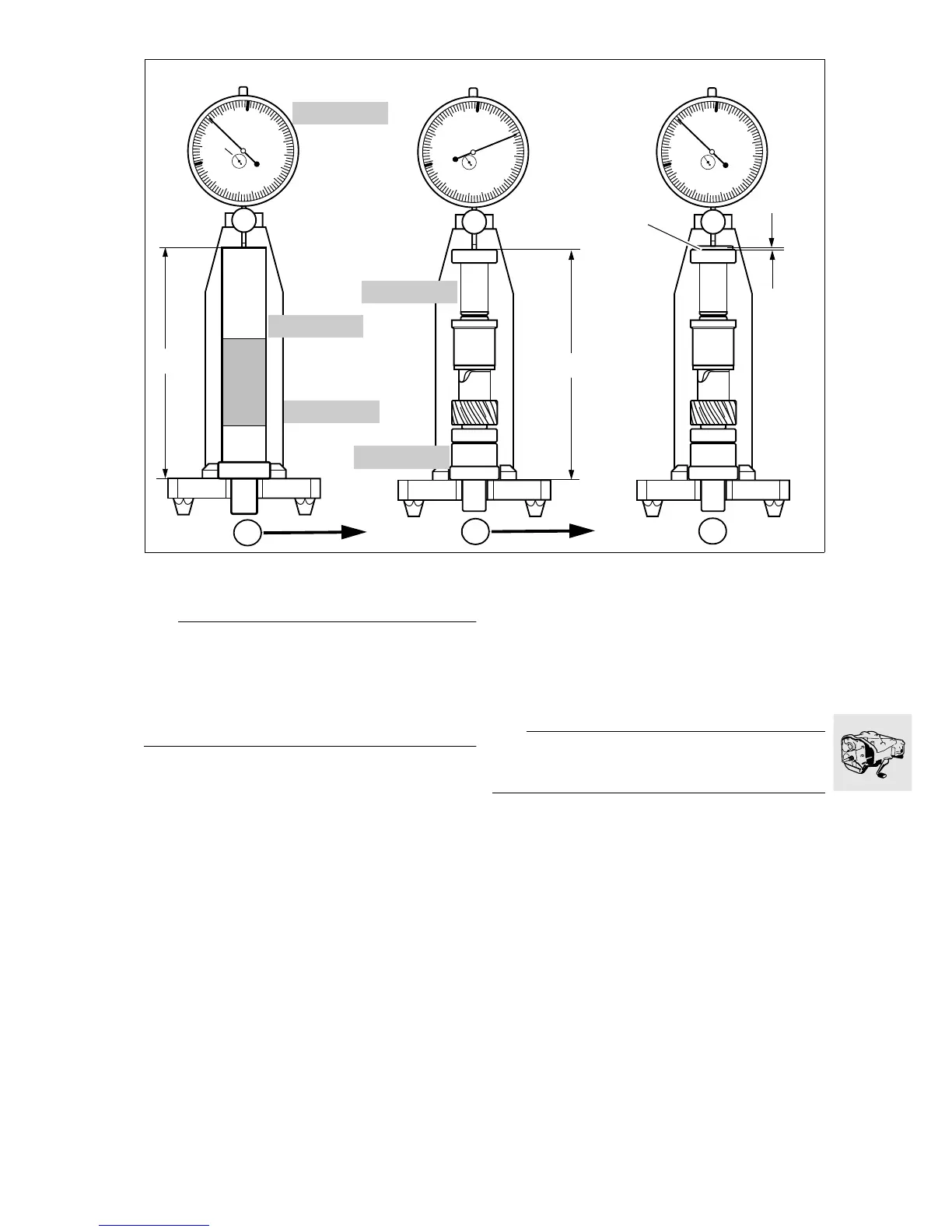

Checking/adjusting fully-compressed length of

input shaft

e Caution:

To adjust and check the fully-compressed length,

deviation from zero must be measured as described

below, and adjusted by means of a shim washer.

Make sure before each measuring step, even if the

shaft is not being installed, that the deep-groove ball

bearing is fully compressed.

•

Pull off output-side deep-groove ball bearing

with universal puller, BMW No. 00 7 500.

•

Take off the spacing washer.

•

Insert zero gauge, BMWNo.234763, into

measuring stand, BMW No. 23 4 761.

•

Secure dial gauge, BMW No. 23 4 762, in front

mounting hole on measuring stand,

BMW No. 23 4 761, and set to 0.2 mm (0.008 in)

preload.

•

Using dial gauge, zero to dimension “A” of the

zero gauge, BMWNo.234763.

•

Remove the zero gauge from the measuring fix-

ture.

•

Mount measuring disc, BMWNo.234764, on

the input shaft.

•

Place the deep-groove ball bearing on the meas-

uring disc.

•

Insert input shaft with adapter disc,

BMW No. 23 4 767, in measuring stand.

•

Using the dial gauge, measure deviation from

zero to dimension “B” at the inner bearing race.

The deviation from zero represents the thickness

“C” of spacing washer (1).

•

Place a spacing washer (1) of the determined

thickness on the inner bearing race and check

the deviation from zero.

A = B + C

e Caution:

The maximum deviation from zero must not be ex-

ceeded.

•

Take the input shaft out of the measuring fixture.

•

Take off the adapter disc, spacing washer, deep-

groove ball bearing and measuring disc.

•

Place a spacing washer (1) of the determined

thickness in position and press the deep-groove

ball bearing on to the input shaft.

Adjusting dimensions for input shaft:

Maximum deviation

from zero ......... -0.05 mm (0.002 in) … 0.00 mm/in

Fully-compressed

length......... 138.55…138.60 mm (5.455…5.457 in)

0

90

10

20

30

40

50

60

70

80

0

90

10

20

30

40

50

60

70

80

0

90

10

20

30

40

50

60

70

80

23 4 762

KR230290

23 4 767

23 4 764

0.2

1

2

3

23 4 763

23 4 761

1

C

B

A

Loading...

Loading...