36.11

Removing/installing spokes

e Caution:

It is not permitted to replace more than one spoke.

•

Unfasten grub screw (1).

•

Loosen the spoke nipple/remove the spoke.

•

Install new spoke.

•

Center the wheel rim.

X Tightening torque:

Spoke nipple ................................................. 5 Nm

Centering the wheel rim

Max. permissible

lateral/vertical runout.................. 1.3 mm (0.05 in)

Max. horizontal runout which can

be eliminated by centering ......... 2.0 mm (0.08 in)

L Note:

Vertical runout cannot be compensated for by

centering the rim.

Centering lateral runout

•

Determine maximum deviation (plus (+) and mi-

nus (-)).

•

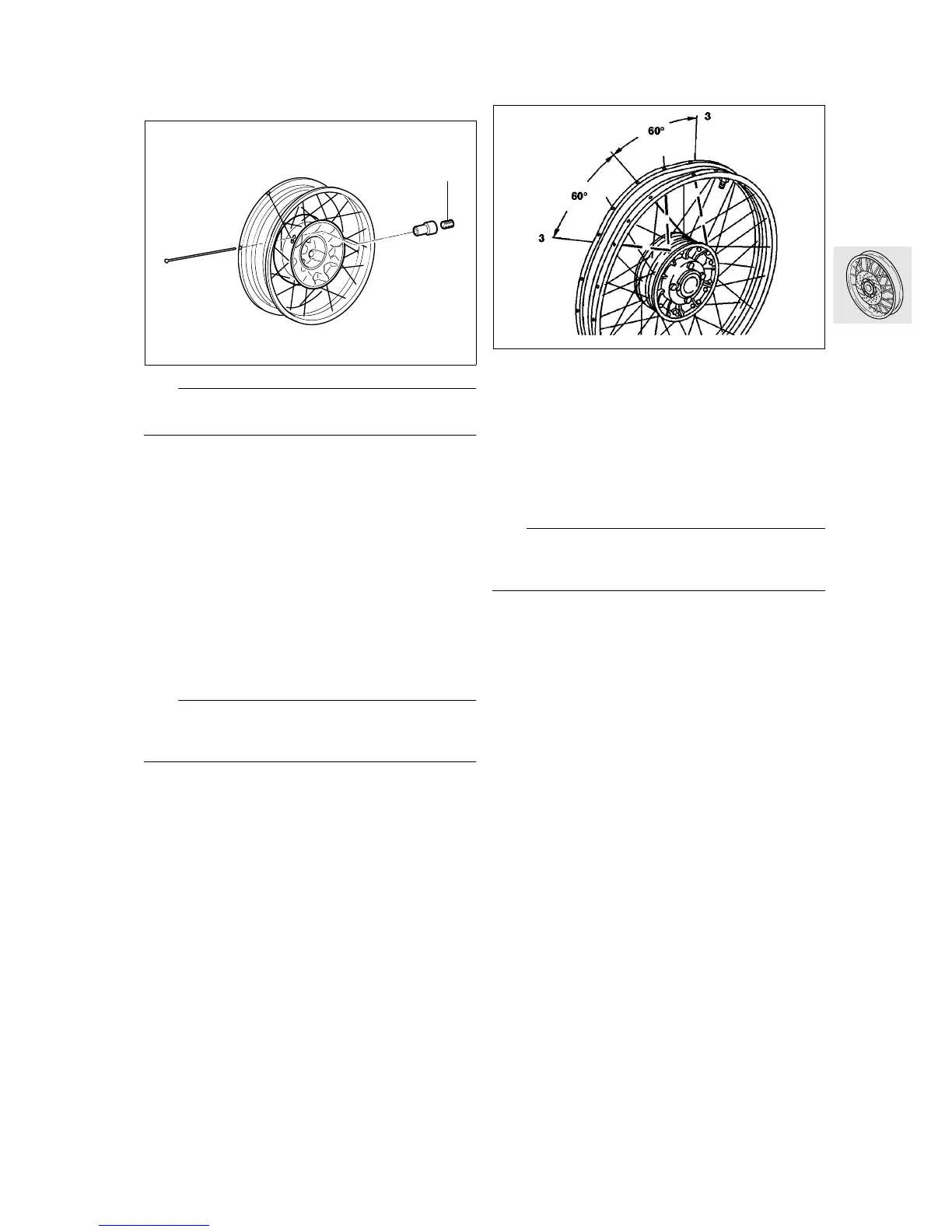

To center the wheel, the spoke nipples must be

tightened on the side directly opposite the larg-

est deviation.

•

Remove grub screw from relevant spoke nipple

before tightening.

•

Working forwards and backwards from the max-

imum and minimum value points, take up slack at

every third spoke nipple.

e Caution:

Never attempt to compensate for the entire horizon-

tal runout at only one or two spokes.

•

At the point where the maximum plus and minus

values occur, take up slack at 2 spokes.

•

Four spokes are therefore tightened during each

centering operation.

•

Check horizontal runout with a dial gauge.

•

After every correction of horizontal runout, check

vertical runout again.

•

If necessary, repeat the centering operation.

•

Lock tightened spokes into place with grub

screws.

X Tightening torque:

Spoke nipple.................................................. 5 Nm

Grub screw .................................................... 1 Nm

C360050

1

GS360090

Loading...

Loading...