66

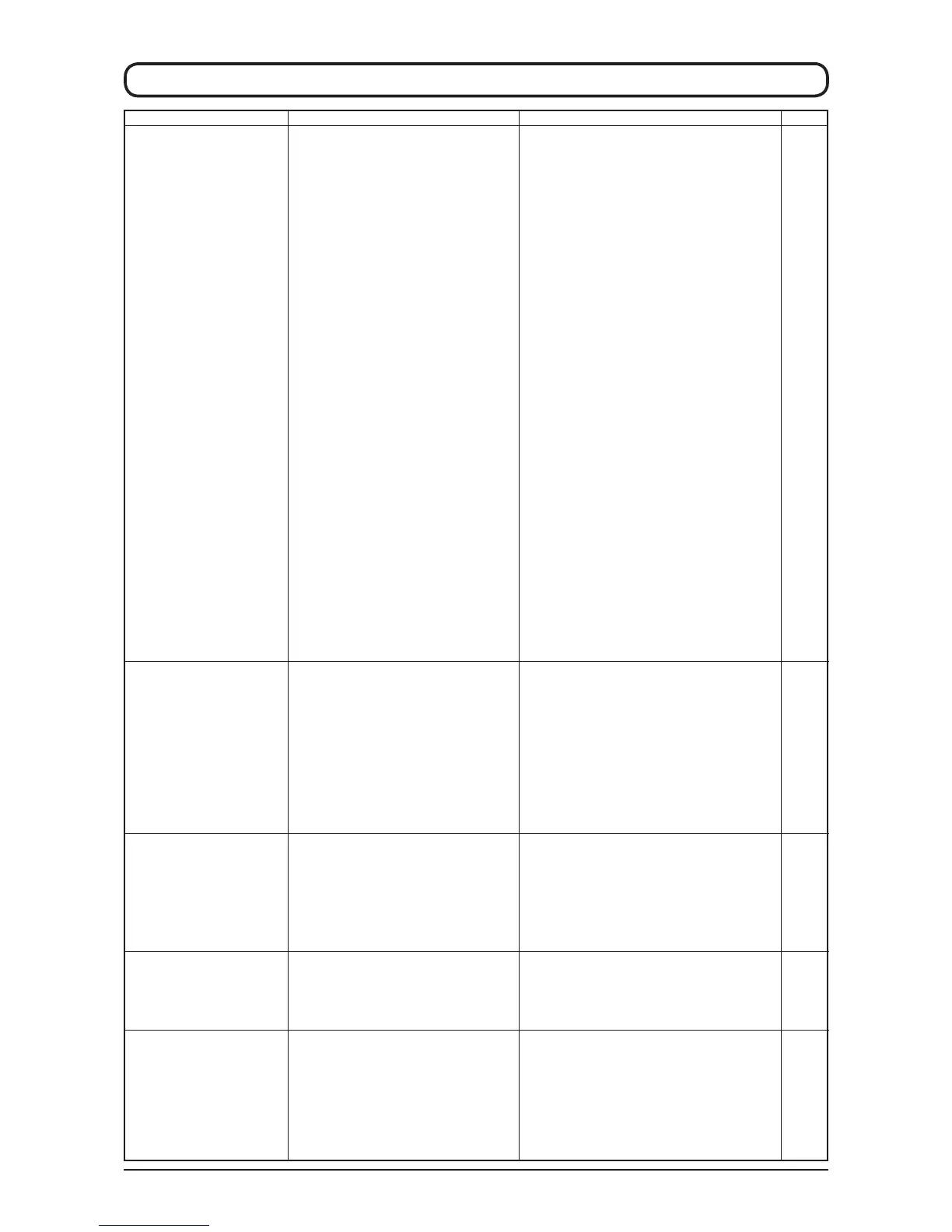

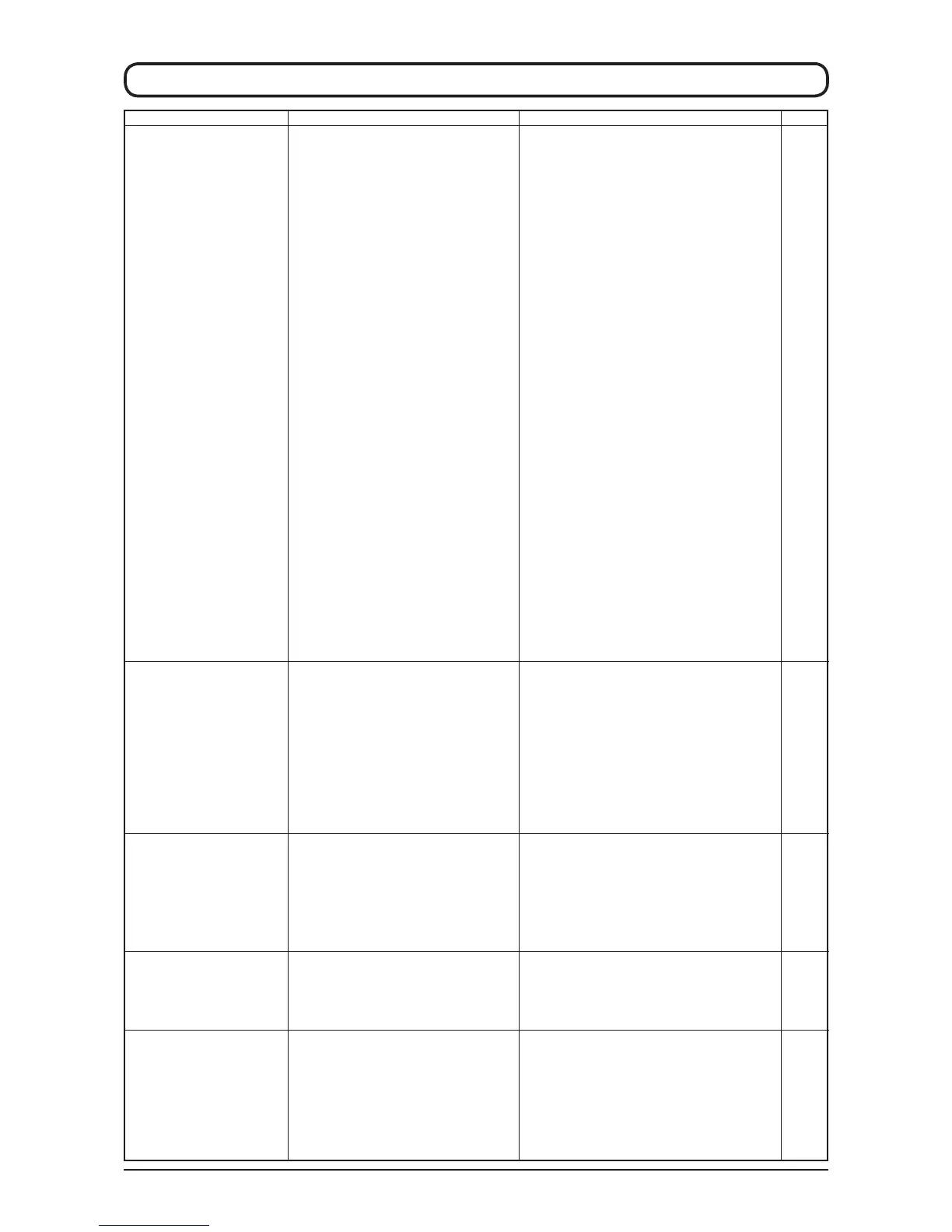

13. TROUBLES AND CORRECTIVE MEASURES IN SEWING

Corrective measure

• Check and replace the needle.

• Use DO x 558 needle.

• Adjust the clearance at the time of inside needle or

outside needle.

• Check and adjust the clearance.

• Adjust the center of the needle.

• Adjust the timing with the stitch bite width used.

• Adjust the timing to open/close the spreader by the

stitch bite width used.

• Remove the cloth waste from the spreader. Replace the

spreader with a new one.

• Check the clearance and properly adjust it.

• Set the thread tension to the proper value.

• Correct the looper with oil-stone or the like, or replace it

with a new one.

• Check and adjust the height of the needle bar.

• Replace the looper or the spreader with a new one

suitable for the stitch bite width.

• Adjust the clearance at the time of inside needle or

outside needle with the needle size used.

• Adjust the timing to open/close the spreader with the

needle size used.

• Use the throat plate suitable for the needle.

• Decrease the needle thread tension. Lower the installing

position of thread take-up thread guide

.

•

Decrease the number of revolution of the sewing machine.

• Change the needle to a thicker one. Adjust the stitch

base line offset.

• Re-set the cut space.

• Decrease the needle thread tension at the time of

thread trimming.

• Check the installing position and adjust it.

• Check the timing between the needle and the looper,

and adjust it.

• Check the clearance and adjust it.

• Check the looper and replace it with a new one.

• Adjust the feeding amount of needle thread

• Check and adjust the pressure.

• Check the clearance and adjust it properly.

• Decrease the sewing speed of eyelet section.

Correct the presser foot or replace it with a new one.

•

Lift the installing position of thread take-up thread guide

.

• Decrease the needle thread tension. Lower the installing

position of thread take-up thread guide

.

•

Adjust the feeding amount of needle thread.

•

Check and adjust the timing between the needle and the looper.

• Check and adjust the opening amount of the spreader.

• Replace the gimp. Check the thread path of gimp.

• Adjust the sewing conditions to obtain an appropriate

thread tension.

• Check and adjust the clearance.

• Check and replace the respective parts.

• Replace the needle with a proper one.

• Check and replace the needle.

Cause

• The needle is bent. There is a scratchon the

needle. The needle is incorrectly attached.

• Kind of needle is wrong.

• The clearance between the needle and the

looper is too large.

•

The clearance between the needle and the needle

guard is too large or the needle and the needle

guard come in excessive contact with each other.

• The clearance between the needle and the

looper varies according to the turning angle (0˚,

90˚ and 180˚).

•

Improper adjustment of the timing between the

needle and the looper

•

Improper adjustment of the timing to open/close

the spreader The spreader comes in contact with

the needle.

•

Motion to open/close the spreader is not smooth.

• The clearance between the presser foot and the

needle entry point is too large.

• Thread tension is not proper.

• The blade point of looper has worn out.

•

Improper adjustment of the height of the needle bar

• The looper or the spreader not suitable for the

stitch bite width is used.

• Improper adjustment of the clearance between

the needle and the looper

•

Improper adjustment of the timing to open/close

the spreader The spreader comes in contact with

the needle.

•

The needle does not fit the kind of throat plate

(needle size used).

• Thread which is difficult to make loops is used.

(Hard-to-slide thread or the like)

• The needle is bent at the thick section of the

material and stitch skipping occurs.

•

In case of the cut-before knife, the inside needle is

bent at the cutting section and stitch skipping occurs.

• The length of remaining needle thread at the

start of sewing is too short.

• The left-hand spreader is installed incorrectly.

• The timing of the right-hand looper is too early.

• The clearance between the presser foot and the

needle entry point is too large.

•

The looper is bent. There are scratches on the looper.

•

Feeding amount of the needle thread is insufficient.

• Looper thread clamp/looper thread presser is

weak and the looper thread comes off at the

start of sew

ing.

• The clearance between the presser foot and the

needle entry point is too llarge.

• The cloth is flopping.

•

Needle thread loop is too large and falls.

As a result, it is not caught by the looper.

• Needle thread loop cannot be made.

As a result, the looper cannot catch the thread

•

The feeding amount of needle thread is insufficient.

• The timing of the right-hand looper is too late.

• The opening amount of the right-hand spreader

is insufficient.

•

The gimp is too hard.

• The needle thread tension is too high.

• The needle comes in contact with the blade point

of the looper.

•

The thread paths in the needle, loopers,

spreaders, throat plate, etc. have become worn

out or conta

in scratches.

• The thread is too thick or too thin for the needle.

•

There are scratches in the needle holeor needle slot.

Page

9

9

47

47

-

45

49

49

30

,

50

16

,

40

45

45

45

,

64

47

49

w61

16

,

31

24

,

25

9

23

,

33

,

37

31

,

40

48

45

30

,

50

45

31

52

30

,

50

25

50

31

16

、

31

、

40

31

45

49

12

、

32

16

、

31

47

9

、

47

、

48

9

9

Phenomenon

1. Stitch skipping

• When changing needle size

• When kind of thread is

affected

•

When sewing heavy-weight

materials

2.

Stitch skipping at the sewing

start

3.

Stitch skipping at eyelet section

4.

Seam splitting at the sewing

end

5. Needle thread breakage

Loading...

Loading...