DIAGNOSTICS / TROUBLESHOOTING

H550 AE Rev.: 007 kortho KGJ X-series

9.4 Error/warning messages

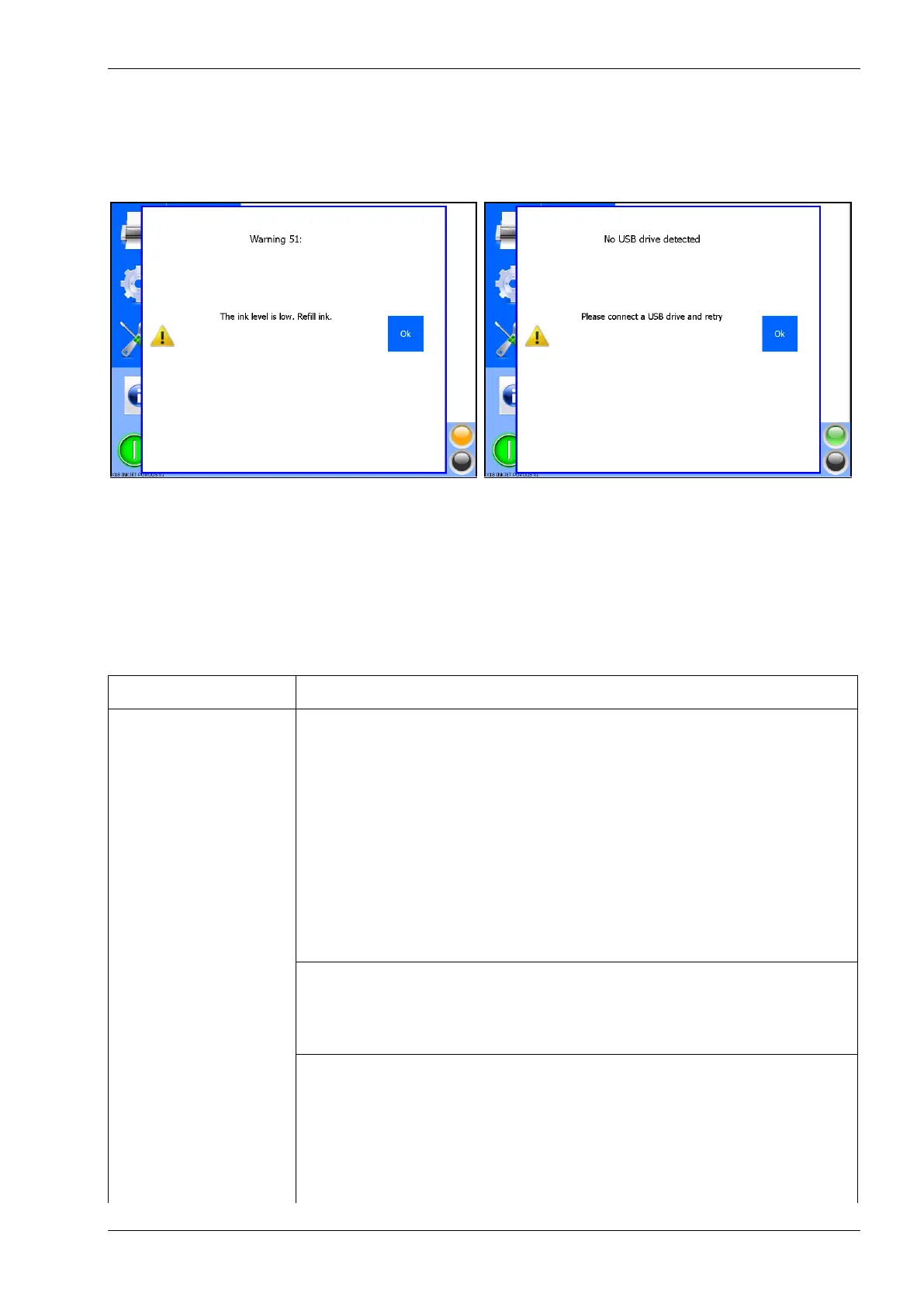

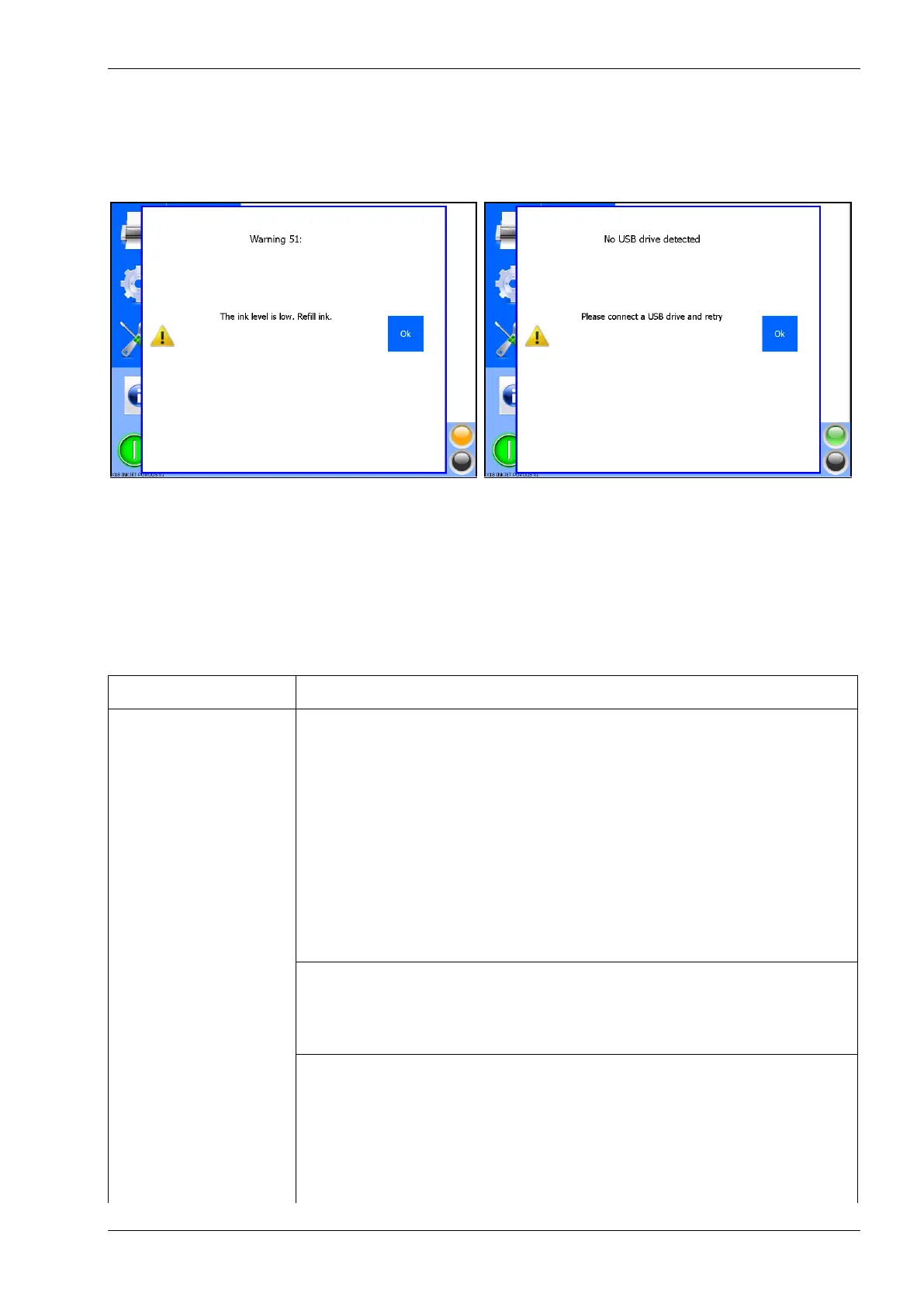

When problems occur the system will generally report an error message. The error message will be displayed on

screen. As example see Fig. 9.39. Depending on the kind of error, the alarm output will also be set. Besides error

messages the system will also report several warnings.

Fig. 9.39 Error/warning message

For a list of all the errors / warnings that can be generated, see Appendix G.

9.5 Poor print quality

9.5.1 General issues

Poor print quality in

general.

Make sure there is enough ink in the ink reservoir (only refill when the ink low

LED is lit!).

Check whether the ink reservoir is at the right level.

Check whether the ink reservoir is levelled.

One or more nozzles might be blocked or partially blocked. Clean the front plate

of the printhead by squirting some cleaner to the front plate (do not rub against

the front plate, this might damage the front plate and/or dirt might be pushed

into the nozzles which will cause a permanent blockage of these nozzles).

Prime the coding unit, to remove the air out of the system.

Purge the system, to see if the printhead is still ok. If not, replace the head filter

and check the print again.

If all else fails, replace the printhead if required.

When using fixed speed:

The set speed doesn’t matches the actual speed and/or the actual speed is

fluctuating too much. Set the speed at the right value and/or make sure the

substrate is moving at a stable speed

When using an external encoder:

Make sure the specs of the encoder match the required system specs.

Check whether the encoder is in constant contact with the substrate/the conveyor

belt and if there is no slip between the encoder wheel and the substrate/the

conveyor belt.

The actual speed is fluctuating too much. Make sure the substrate is moving at a

relative stable speed.

Loading...

Loading...