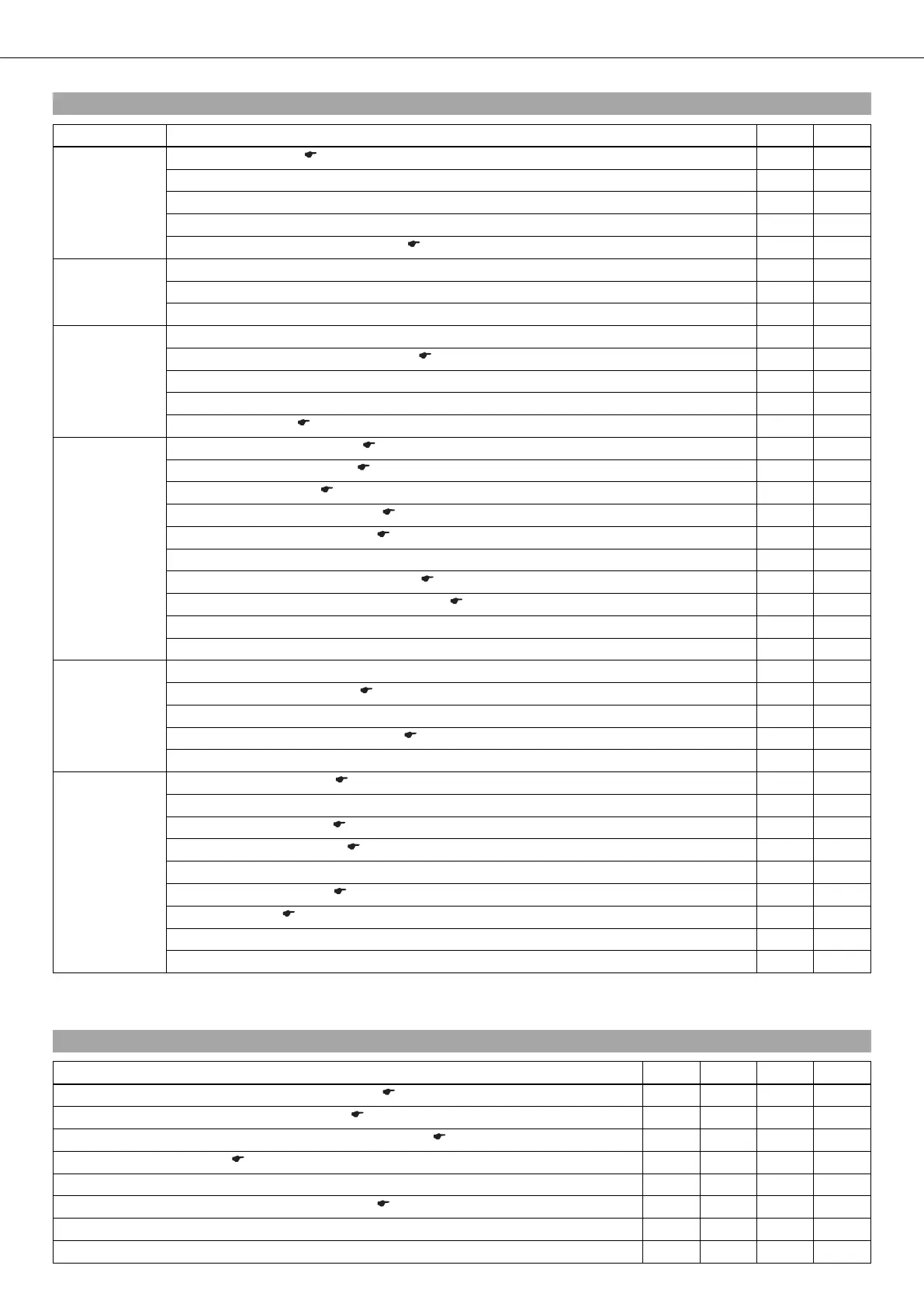

SERVICE SCHEDULE 134

34.1Important maintenance work that must be done in an authorized KTM workshop

S20A S40A

Engine Change the gear oil. ( p. 115) •

Check spark plug and replace if required. • •

Clean spark plug connectors and check for tightness. • •

Check engine mounting screws for tightness. • •

Check the clutch engagement speed. ( p. 110) • •

Carburetor Check intake flange and carburetor connection boot for cracks and leakage. •

Check idle. • •

Check vent hoses for damage and routing without sharp bends. •

Attachments Check the cooling system for leakage. •

Check the antifreeze and coolant level. ( p. 113) •

Check exhaust system for leakage and looseness. • •

Check throttle cables for damage, smooth operation and routing without sharp bends. •

Clean the air filter. ( p. 41) • •

Brakes Check the front brake linings. ( p. 56) •

Check the rear brake linings. ( p. 61) •

Check the brake discs. ( p. 47) •

Check the front brake fluid level. ( p. 53) • •

Check the rear brake fluid level. ( p. 59) • •

Check brake lines for damage and leakage. •

Check the play of the hand brake lever. ( p. 53) • •

Check the free travel of the foot brake lever. ( p. 58) • •

Check the function of the brake system. • •

Check screws and guide bolts of brake system for tightness. • •

Chassis Check shock absorber and fork for leakage and functioning. • •

Clean dust boots of fork legs. ( p. 9) • •

Check swingarm bearing. •

Check play of steering head bearing. ( p. 18) •

Check all screws to see if they are tight. • •

Wheels Check the spoke tension. ( p. 48) • •

Check rim run-out. • •

Check the tire condition. ( p. 47) • •

Check the tire air pressure. ( p. 47) • •

Check the chain wear. • •

Check the chain tension. ( p. 50) • •

Clean the chain. ( p. 50) • •

Check wheel bearing for play. • •

Clean and grease adjusting screws of chain adjuster. • •

S20A: Every 20 operating hours

S40A: Every 40 operating hours

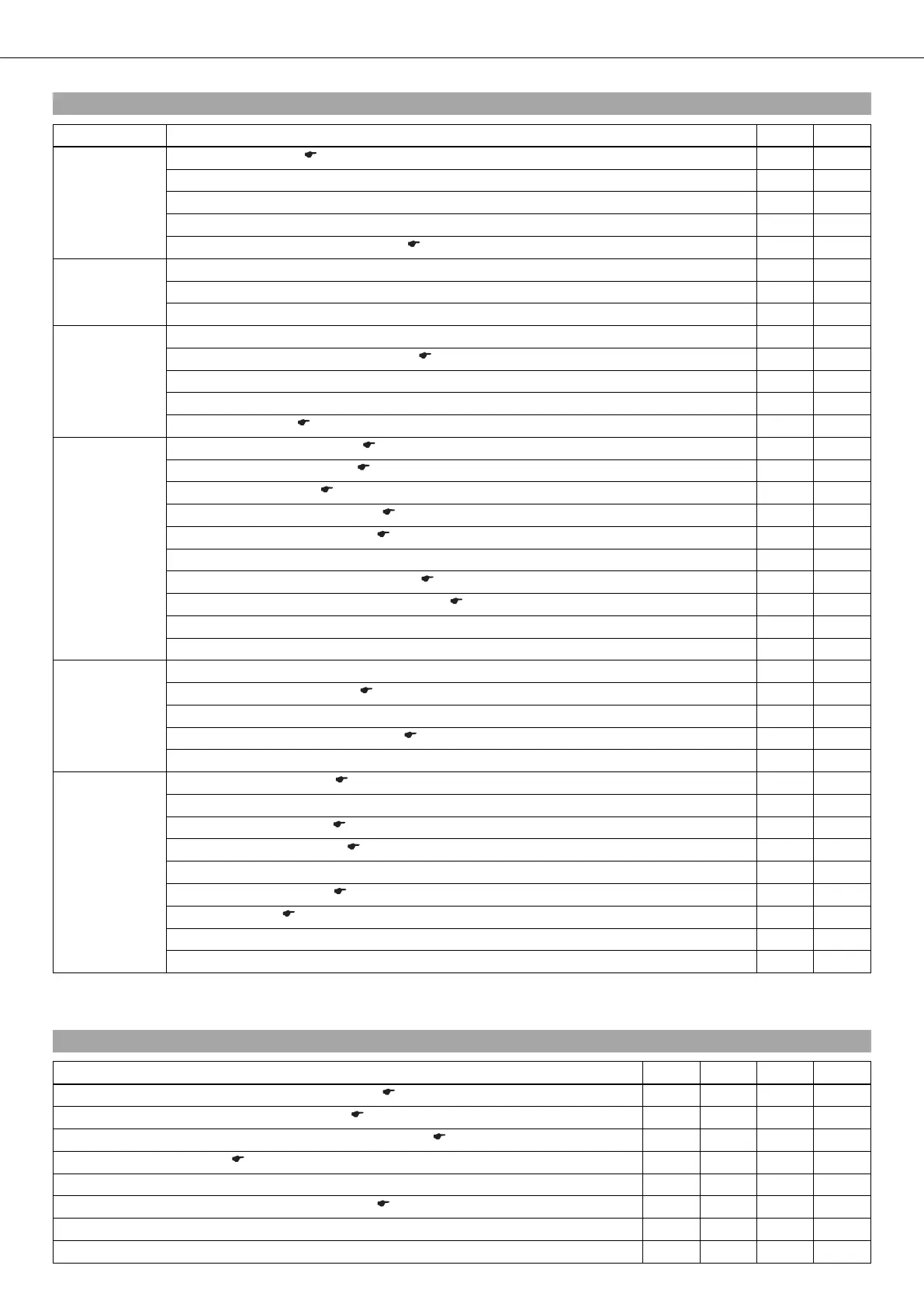

34.2Important maintenance work that must be done in an authorized KTM workshop (as additional order)

S20A S40A S80A J1A

Check/set the carburetor components. (50 SX Mini) ( p. 99) •

Check/set the carburetor components. (50 SX) ( p. 98) •

Check the reed valve housing, diaphragm and intake flange. ( p. 83) • • •

Check/measure the clutch. ( p. 81) • • •

Checking wear of clutch drum. • • •

Determine the piston/cylinder mounting clearance. ( p. 82) • • •

Check the seating of the piston pin. • • •

Check main bearing of the crankshaft. • • •

Loading...

Loading...