30/ASSEMBLING THE ENGINE 91

300466-11

– Slide piston pin into the connecting rod by hand.

400541-10

– Position the piston pin retainer in the 6 o'clock or 12 o'clock position.

– Ensure that the piston pin retainer is correctly seated on both sides.

– Remove the cloth.

17.25Installing the cylinder

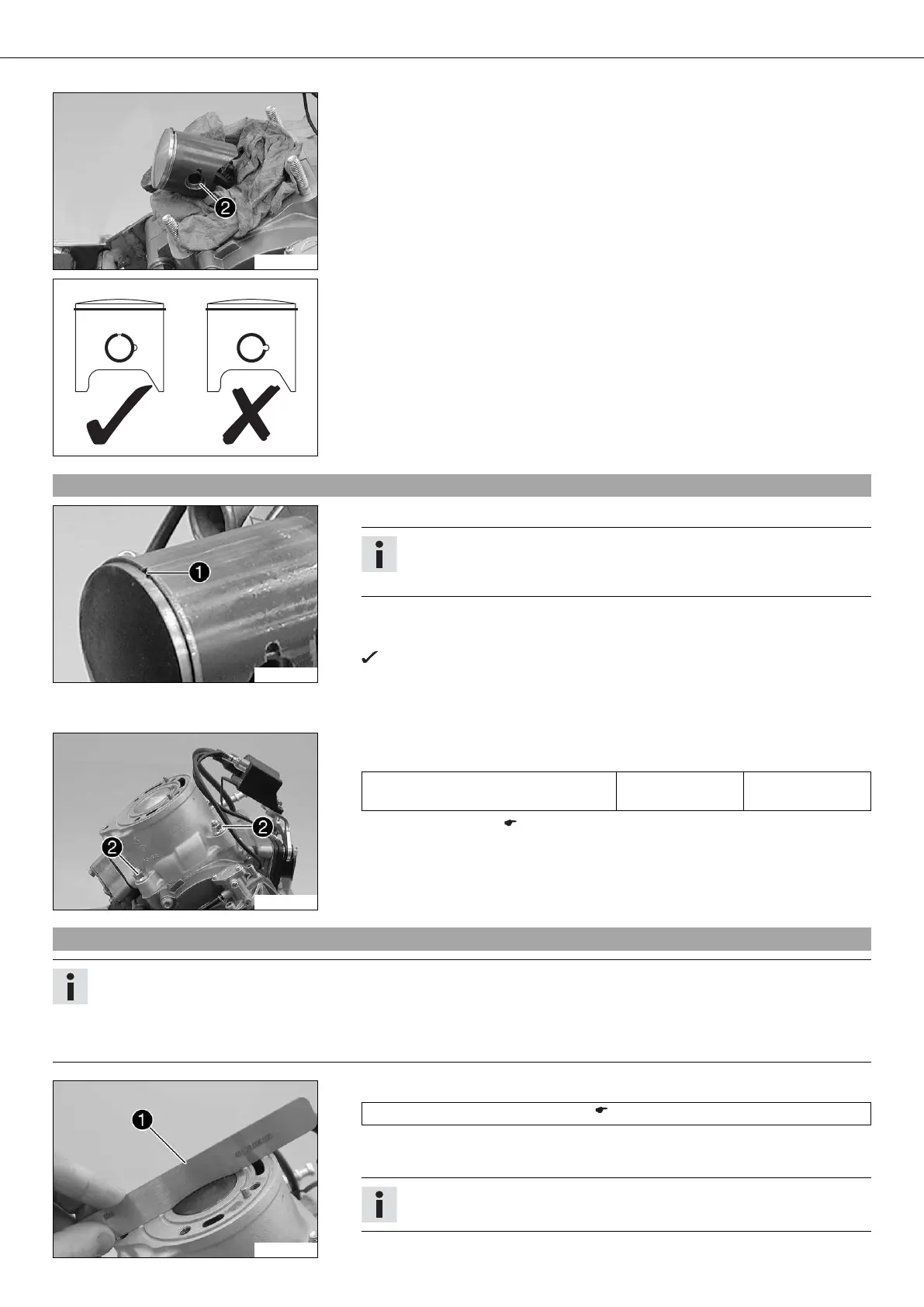

300465-10

– Position the new cylinder base gasket.

Info

If neither the piston, cylinder, crankshaft or engine case need to be

changed, the same gasket thickness can be used as before.

– Oil the cylinder and piston.

– Position the piston ring.

The anti-rotation lock engages in piston ring end .

– Slide the cylinder over the piston.

– Carefully push the cylinder down and ensure that the dowel pins are properly

engaged.

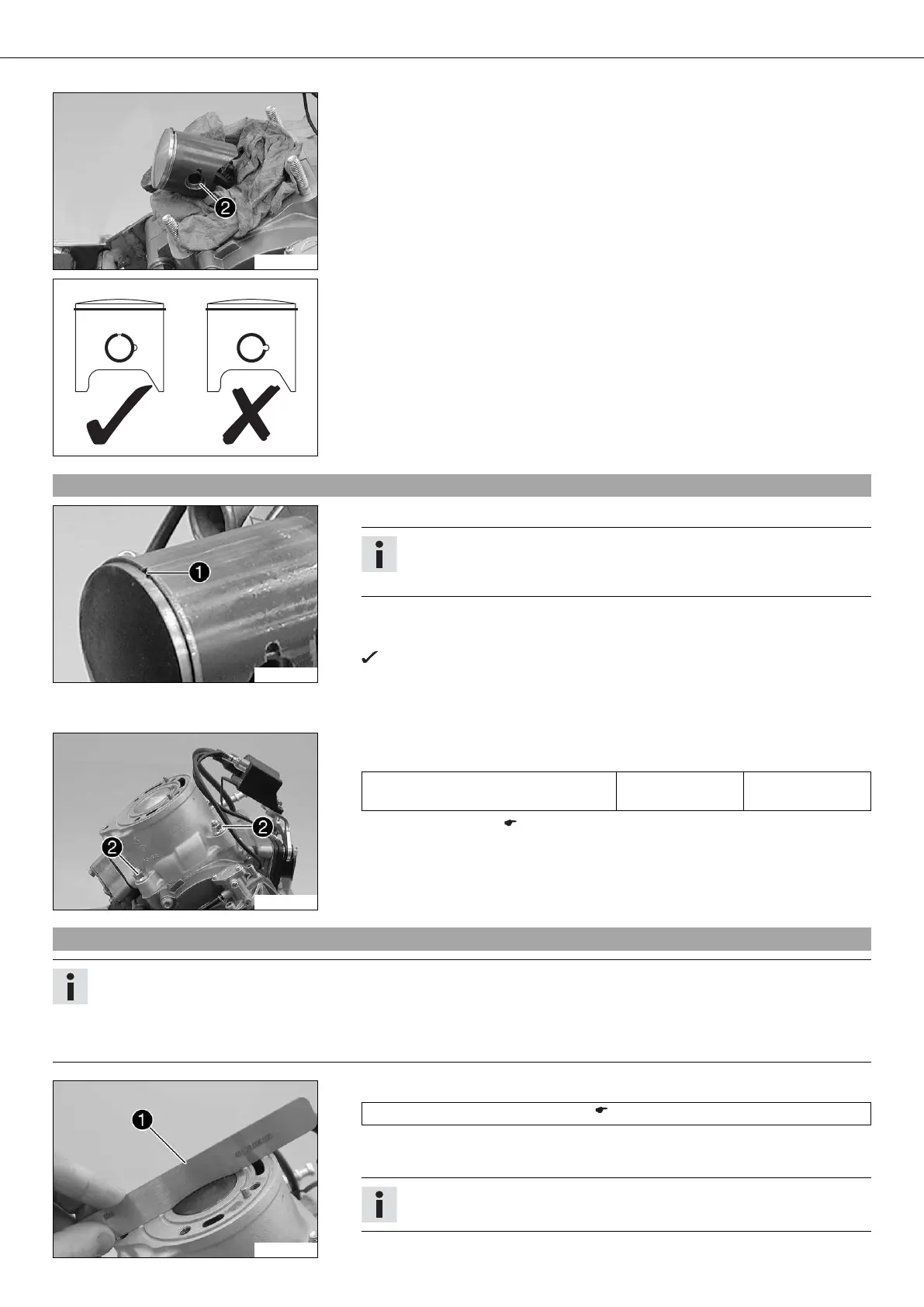

300464-11

– Mount nuts on both sides and tighten in a crisscross pattern.

Guideline

Nuts, cylinder base M8 20 Nm

(14.8 lbf ft)

– Check the X-distance. ( p. 91)

17.26Checking the X-distance

Info

The X-distance is the distance defined for the piston protrusion, when the cylinder is clamped down and the piston is at top

dead center.

The X-distance must be checked very carefully. If the X-distance is too large, the compression decreases and the engine loses

power. If the X-distance is too small, the engine knocks and overheats.

300502-10

– Apply special tool to the cylinder.

Adjustment gauge (45129006000) ( p. 142)

– Position the piston at top dead center.

– Check the X-distance.

Info

The piston should not raise the gauge off of the cylinder.

Loading...

Loading...