ENGINE MECHANICAL SERVICE MANUAL NUMBER 22

Page 3A-106 90-860074--1 FEBRUARY 2002

Connecting Rod / Piston Assembly

Measuring Rod Bearing Clearance

1. Remove oil pan and oil pick-up tube assembly.

2. Turn crankshaft to gain access to connecting rod bolts.

3. One cylinder at a time, remove rod caps and inspect bearings. Refer to Bearing Failure.

4. Measure crank pin with a micrometer for out-of-round, taper, or excessive wear. If not

within specifications, replace or recondition crankshaft.

5. Measure new or used bearing clearances with Plastigage or its equivalent as follows:

a. Clean oil from crank pin.

b. Install bearing in connecting rod.

c. Place a piece of gauging plastic the full width of crank pin (parallel to crankshaft).

d. Install rod cap with bearing. Torque bolts to 29.4 Nm + 60 degrees (21 lb-ft + 60

degrees).

IMPORTANT: Do NOT turn crankshaft while gauging plastic is in place.

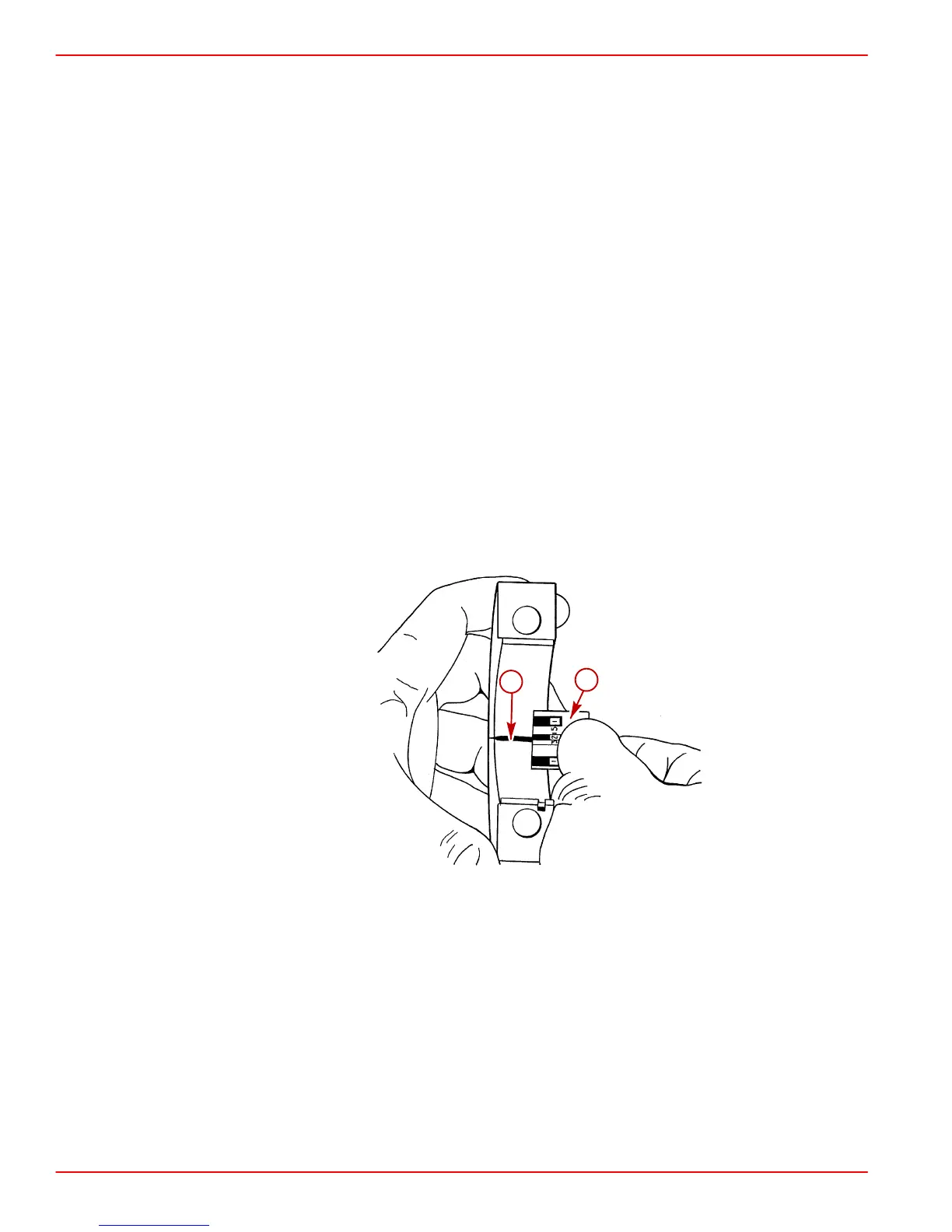

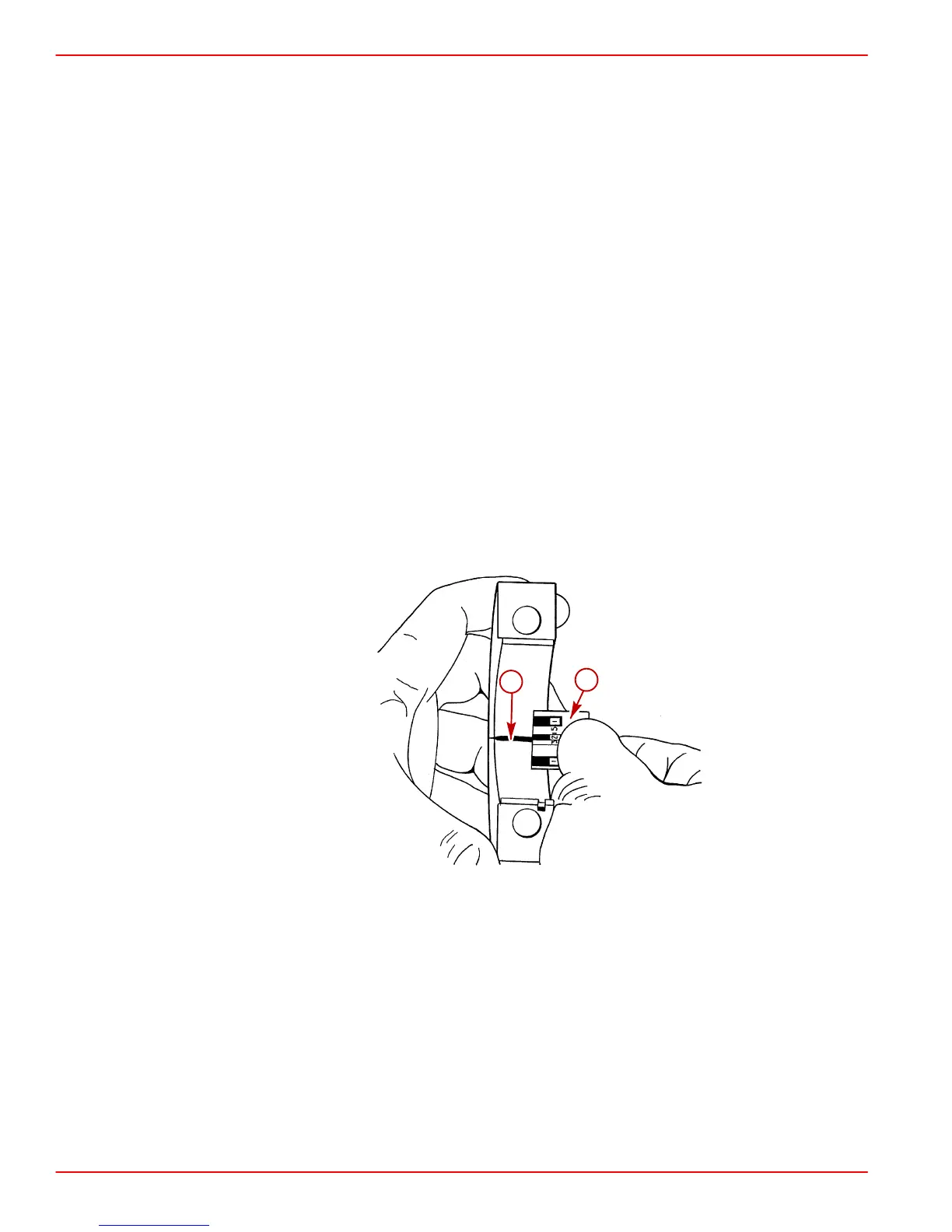

e. Remove rod cap and, using scale on gauging plastic envelope, measure gauging

plastic width at widest point.

72358

a

b

Typical

a-Compressed Gauging Plastic

b-Graduated Scale

Loading...

Loading...