ENGINE MECHANICAL SERVICE MANUAL NUMBER 22

Page 3A-138 90-860074--1 FEBRUARY 2002

Cleaning and Inspection

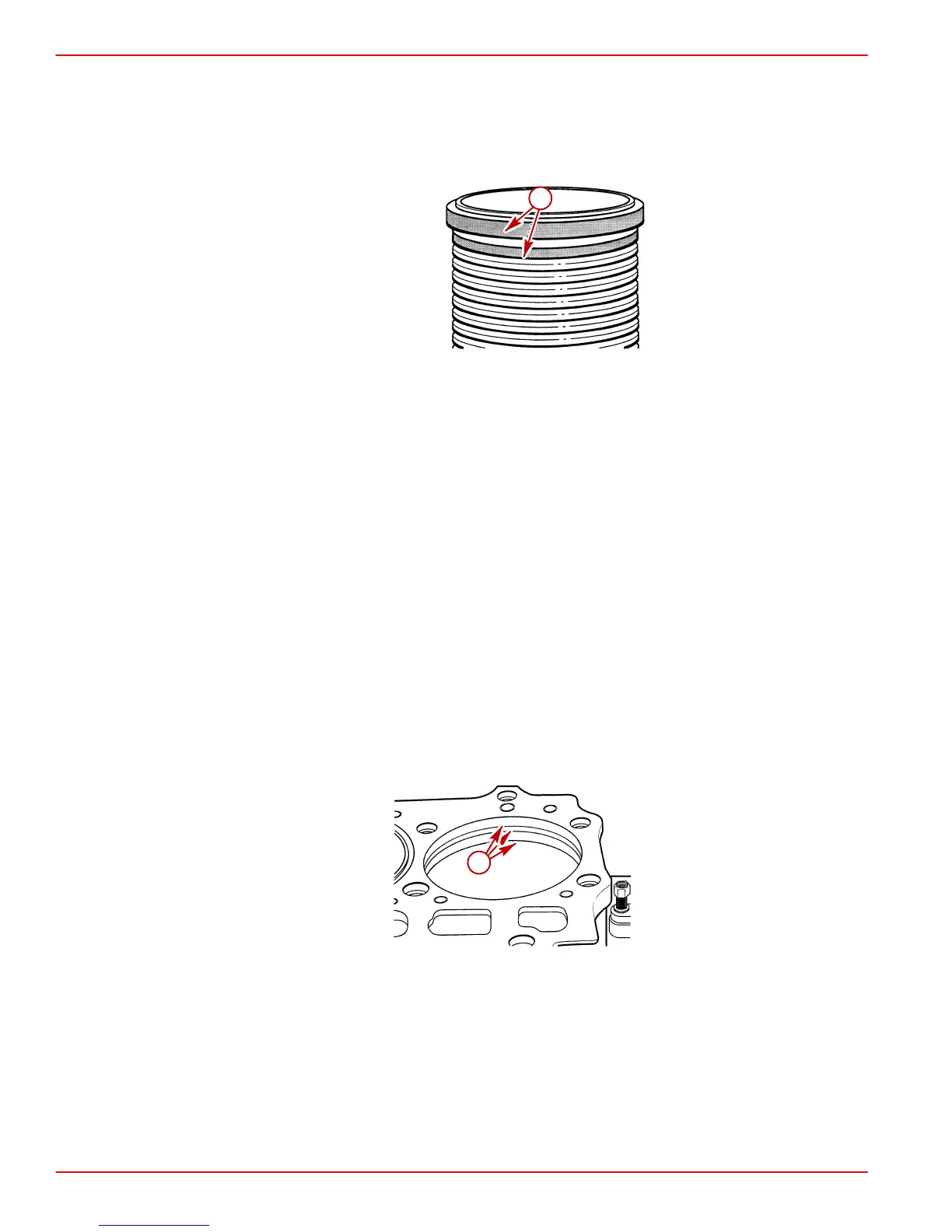

CYLINDER LINERS

1. Clean liners, especially at areas as shown, and where O-rings fit.

70414

a

a-Areas for Special Cleanliness

2. Check liners for abnormal wear or cracks. Replace as needed with those parts for your

specific model.

3. Measure liners for out-of-round or taper with a dial or bore gauge, taking readings at

three different vertical positions and at opposite sides of the liner bore. Refer to

specifications.

4. When cylinder liner wear is within specifications light honing of the liner bore is allowed.

Replace if liners are not within specifications.

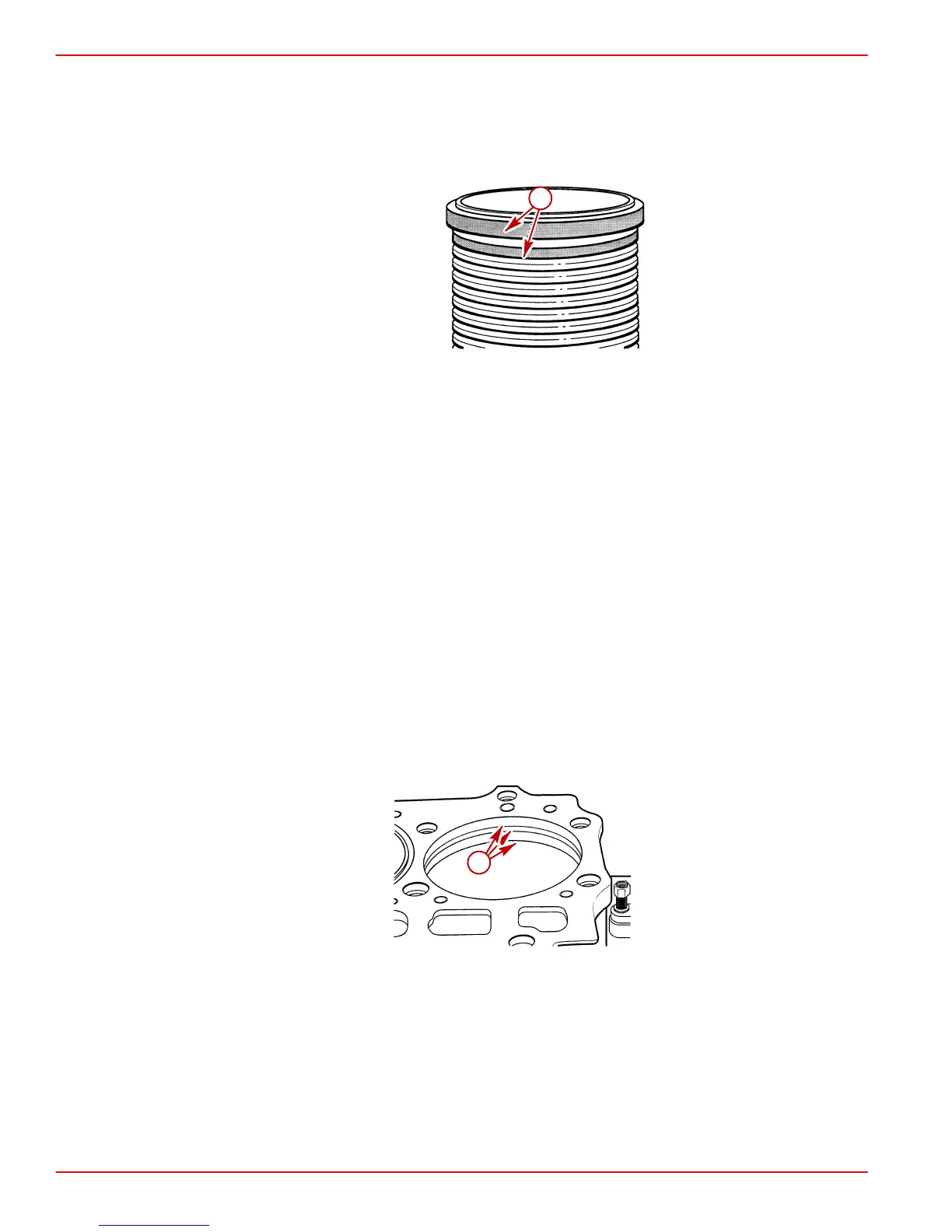

CYLINDER BLOCK (LINER) BORES

1. Thoroughly clean the cylinder block with suitable solvent and blow dry with compressed

air. Inspect for cracks or flaws.

2. Check cylinder head mating surfaces of block and area around cylinder liner bores for

abnormal wear or damage.

3. Check block bores for damage and cleanliness, especially the flanges and counterbores

for cylinder liners as shown.

70415

a

a-Areas for Special Cleanliness

4. If any checks or inspections reveal unacceptable conditions replace parts as needed

with those for your specific model.

Loading...

Loading...