CLOSED COOLING SYSTEM

SERVICE MANUAL NUMBER 22

90-860074-1 FEBRUARY 2002 Page 6B-15

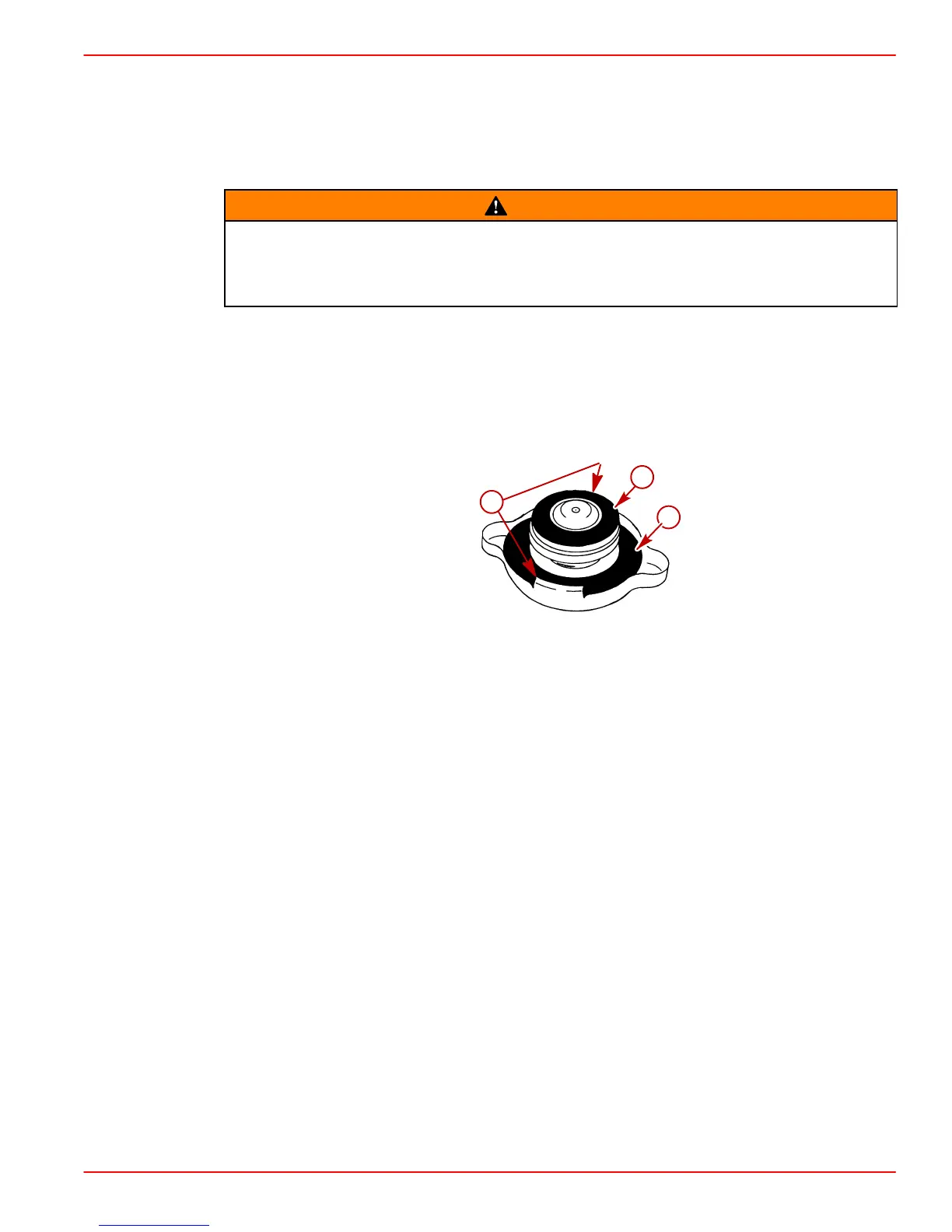

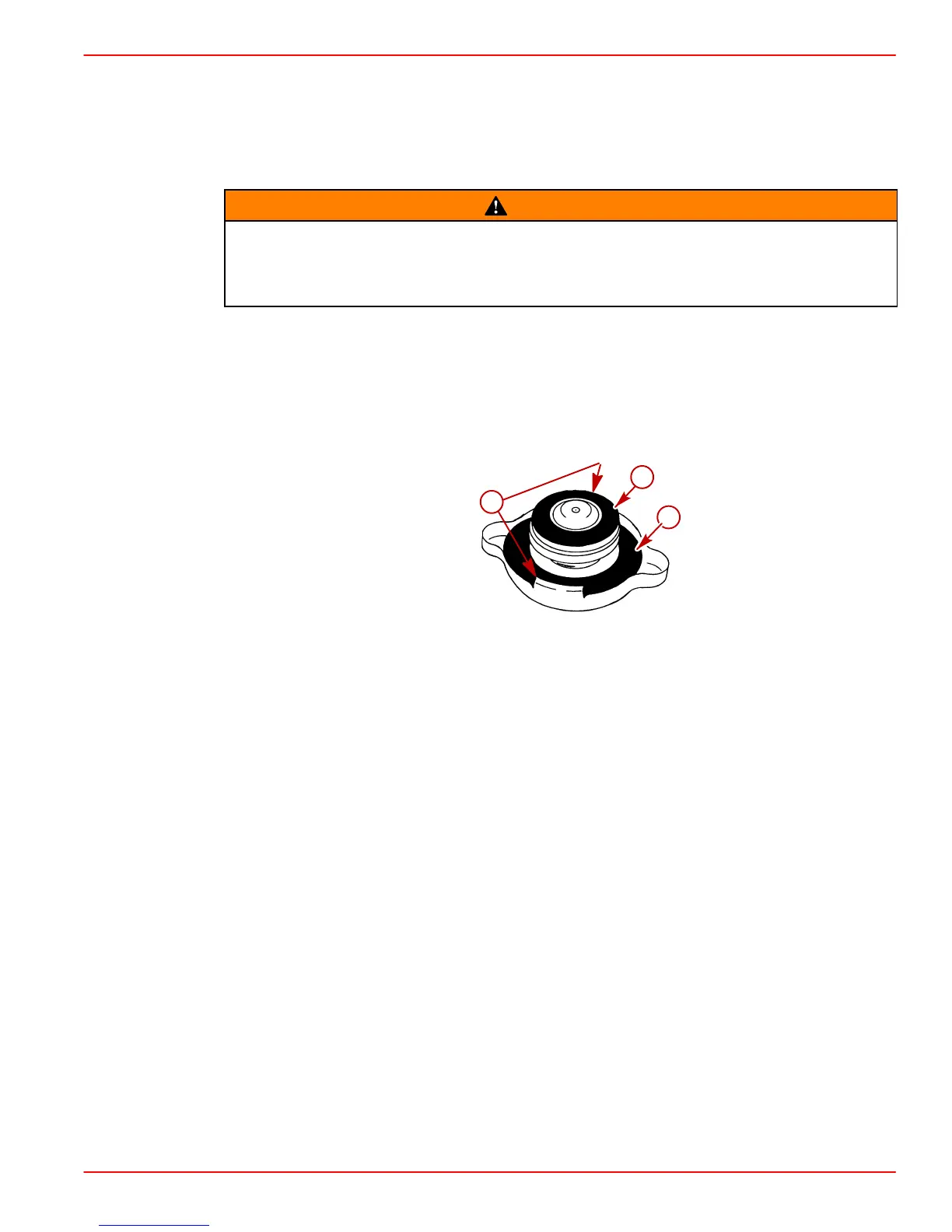

Testing Pressure Cap

Pressure cap is designed to maintain a pressure of approximately its rated capacity (refer

to Specifications) in closed cooled section once engine has attained operating temperature.

Cap should be cleaned, inspected and pressure-tested at regular tune-up intervals or

whenever cap is suspected of maintaining improper pressure.

WARNING

Allow engine to cool before removing pressure cap. Sudden loss of pressure could

cause hot coolant to boil and discharge violently. After engine has cooled, turn cap

1/4 turn to allow any pressure to escape slowly, then push down and turn cap all the

way off.

1. Carefully remove pressure cap from reservoir or heat exchanger.

2. Wash cap with clean water to remove any deposits or debris from sealing surfaces.

3. Inspect gasket (if used) and rubber seal on cap for tears, cuts, cracks or other signs of

deterioration.

4. Replace gasket, if damaged, or entire cap if rubber seal is damaged.

72714

b

c

a

a-Rubber Seal

b-Gasket

c-Locking Tabs (1 Not Shown)

5. Ensure that locking tabs on cap are not bent or damaged.

Loading...

Loading...