Tool offsets

7.3 Special handling of tool offsets

Job planning

396 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

7.3 Special handling of tool offsets

Function

The evaluation of the sign for tool length and wear can be controlled using setting data

SD42900 to SD42960.

The same applies to the behavior of the wear components when mirroring geometry axes or

changing the machining plane, and also to temperature compensation in tool direction.

Wear values:

If reference is made to wear values in the following, then this should be understood as the

sum of the actual wear values ($TC_DP12 to $TC_DP20) and the sum offsets with the wear

values ($SCPX3 to $SCPX11) and setting-up values ($ECPX3 to $ECPX11).

More information on summed offsets, refer to:

References:

Function Manual, Tool Management

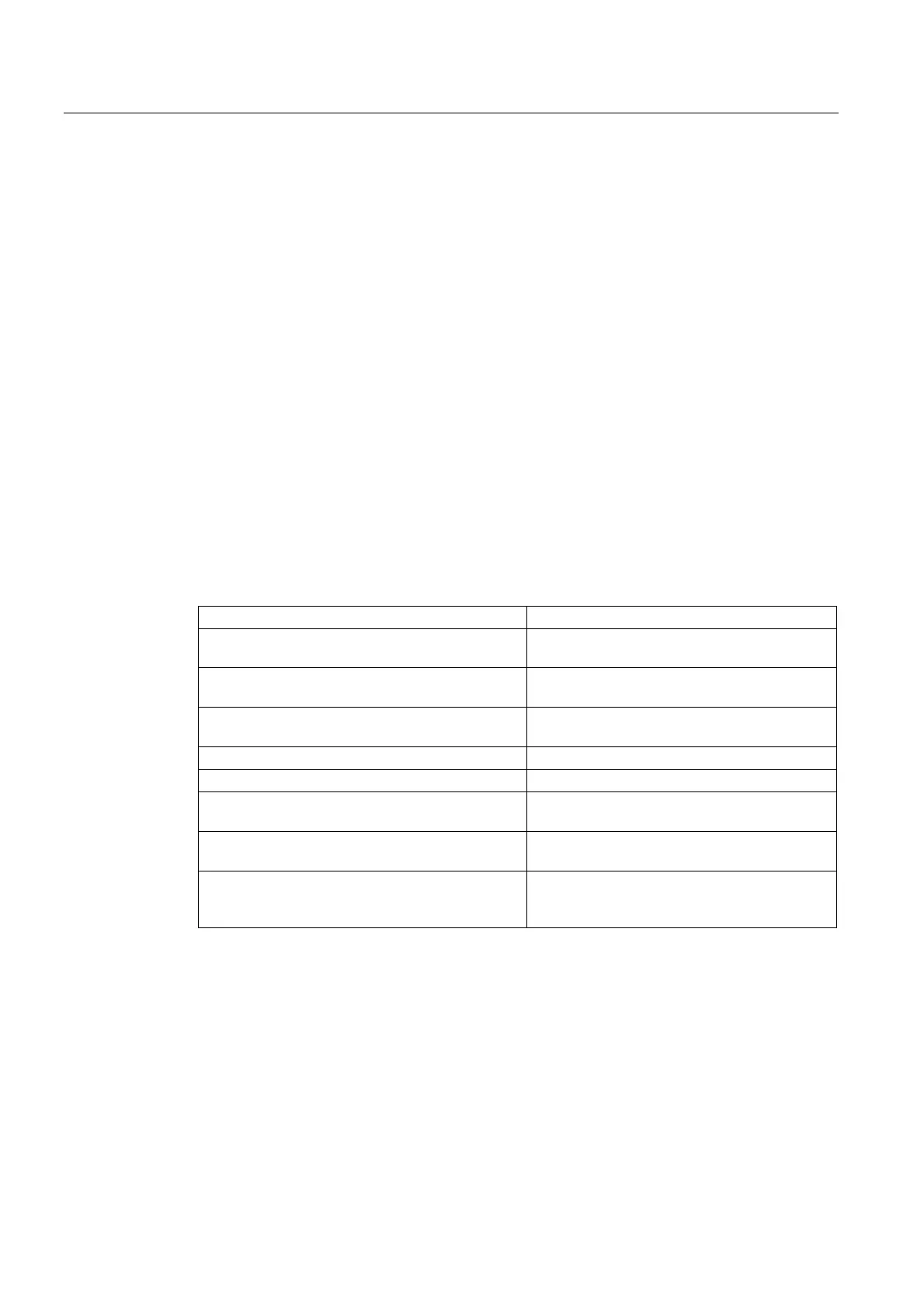

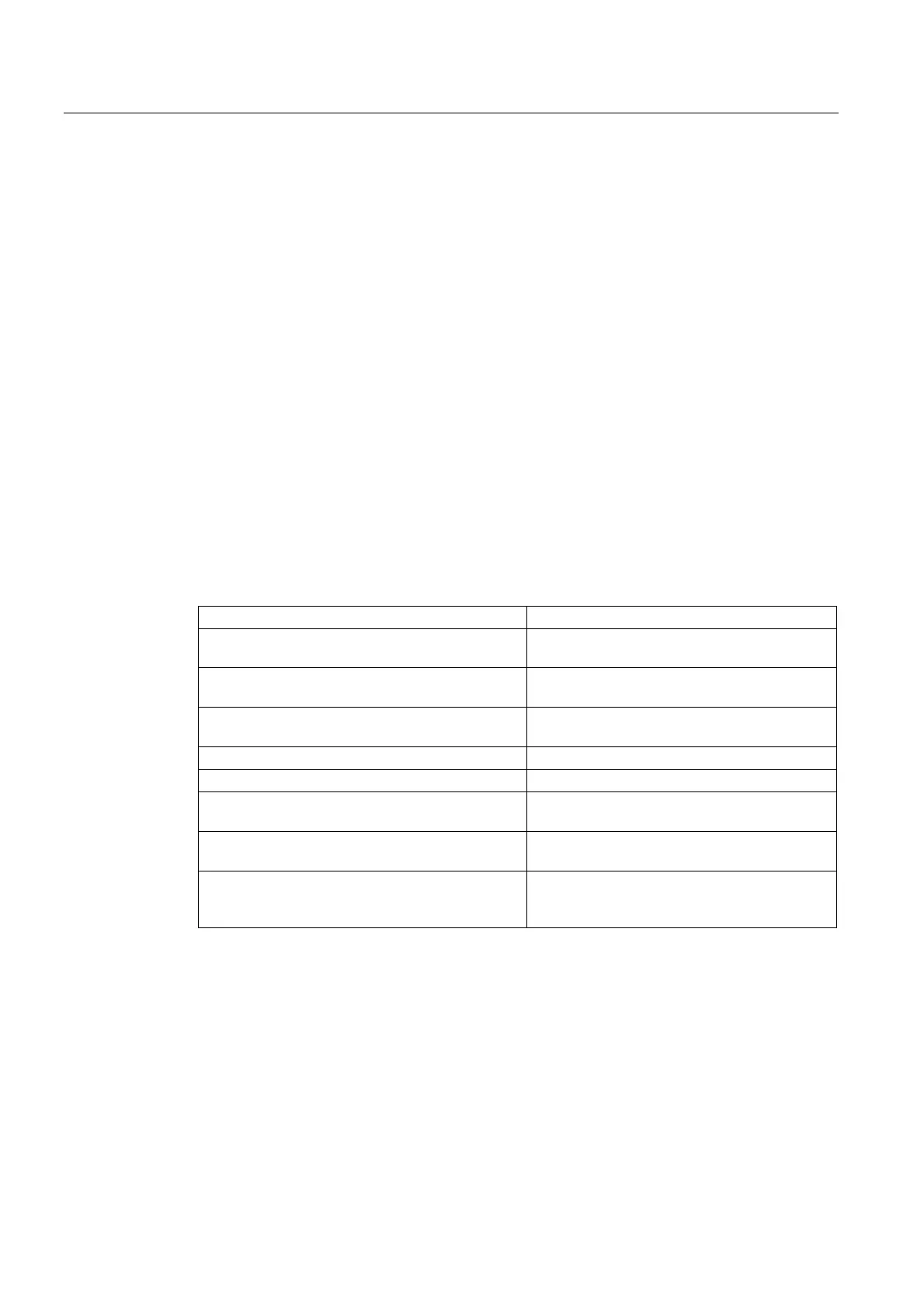

Setting data

Setting Data Significance

SD42900 $SC_MIRROR_TOOL_LENGTH Mirroring of tool-length components and

components of the tool base dimension.

SD42910 $SC_MIRROR_TOOL_WEAR Mirroring of wear values of the tool-length

components.

SD42920 $SC_WEAR_SIGN_CUTPOS Evaluating the sign of the wear components as

a function of the tool nose position.

SD42930 $SC_WEAR_SIGN Inverts the sign of wear dimensions.

SD42935 $SC_WEAR_TRANSFORM Transformation of wear values.

SD42940 $SC_TOOL_LENGTH_CONST Assignment of tool length components to

geometry axes.

SD42950 $SC_TOOL_LENGTH_TYPE Assignment of the tool length components

independent of tool type.

SD42960 $SC_TOOL_TEMP_COMP Temperature compensation value in tool

direction. Also operative when tool orientation is

programmed.

References

Function Manual Basic Functions; Tool Offset (W1)

Loading...

Loading...