Motion synchronous actions

10.1 Basics

Job planning

550 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

Programming

A synchronized action is programmed on its own in a separate block and triggers a machine

function as of the next executable block (e.g. traversing movement with

G0, G1, G2, G3).

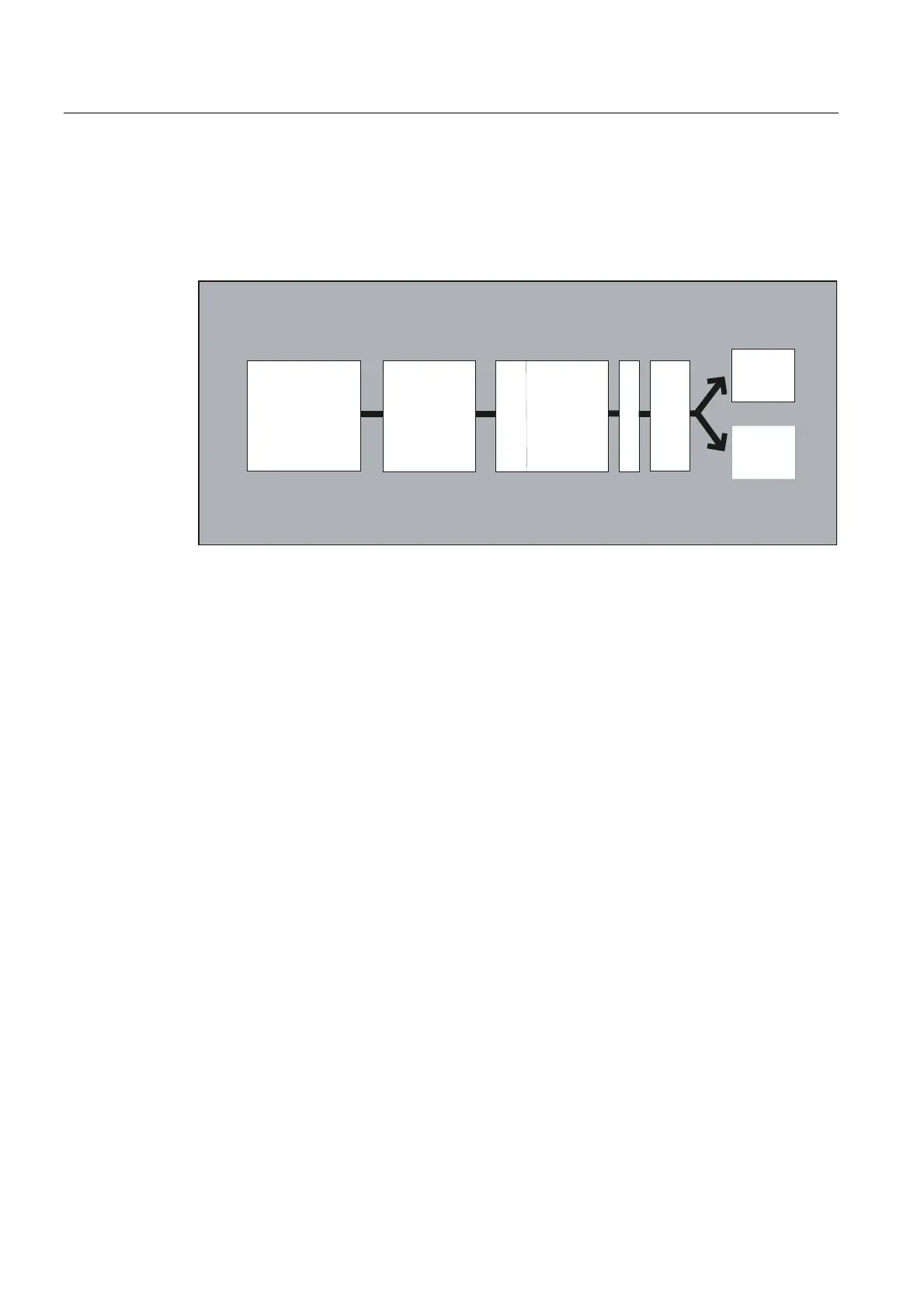

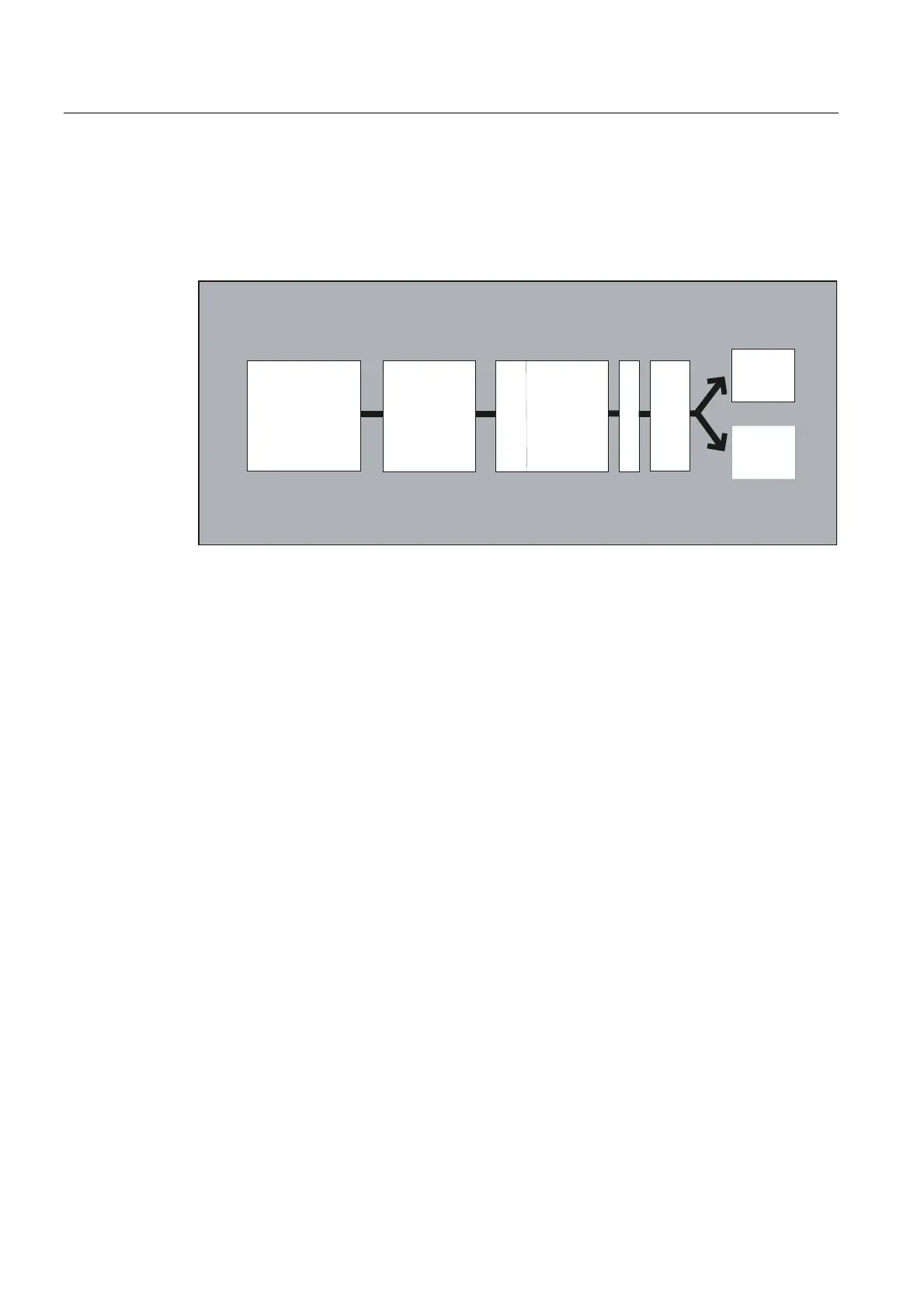

Synchronized actions comprise up to 5 command elements with different tasks:

7HFKQRORJ\

F\FOH

$FWLRQ

2SWLRQDO*FRGH

IRUDFWLRQ

WHFKQRORJ\F\FOH

'2

&RQGLWLRQ

3ROOLQJIUHTXHQF\

.H\ZRUG

5DQJHRIYDOLGLW\

,'QXPEHU

2SWLRQDO*FRGH

IRUFRQGLWLRQ

Syntax:

DO <action1> <action2> …

<KEYWORD> <condition> DO <action1> <action2> …

ID=<n> <KEYWORD> <condition> DO <action1> <action2> …

IDS=<n> <KEYWORD> <condition> DO <action1> <action2> …

Significance:

DO

Instruction to initiate the programmed action(s)

Only effective if the

<condition> is fulfilled (if programmed).

→ See "Actions"

<action1>

<action2>

…

Action(s) to be started

Examples:

• Assign variable

• Start technology cycle

<KEYWORD>

The cyclic check of the

<condition> of a synchronized action is

defined using the keyword (

WHEN, WHENEVER, FROM or EVERY).

→ See "Cyclically checking of the condition"

<condition>

Gating logic for main run variables

The condition is checked in the IPO clock cycle

ID=<n>

or

IDS=<n>

Identification number

The area of validity and the position within the machining

sequence is defined using the identification number.

→ See "Area of validity and machining sequence"

Loading...

Loading...