Tool offsets

7.4 Online tool offset (PUTFTOCF, FCTDEF, PUTFTOC, FTOCON, FTOCOF)

Job planning

404 Programming Manual, 07/2010, 6FC5398-2BP40-0BA0

7.4 Online tool offset (PUTFTOCF, FCTDEF, PUTFTOC, FTOCON,

FTOCOF)

Function

When the "Online tool offset" function is active, a tool length offset resulting from the

machining is applied immediately on grinding tools.

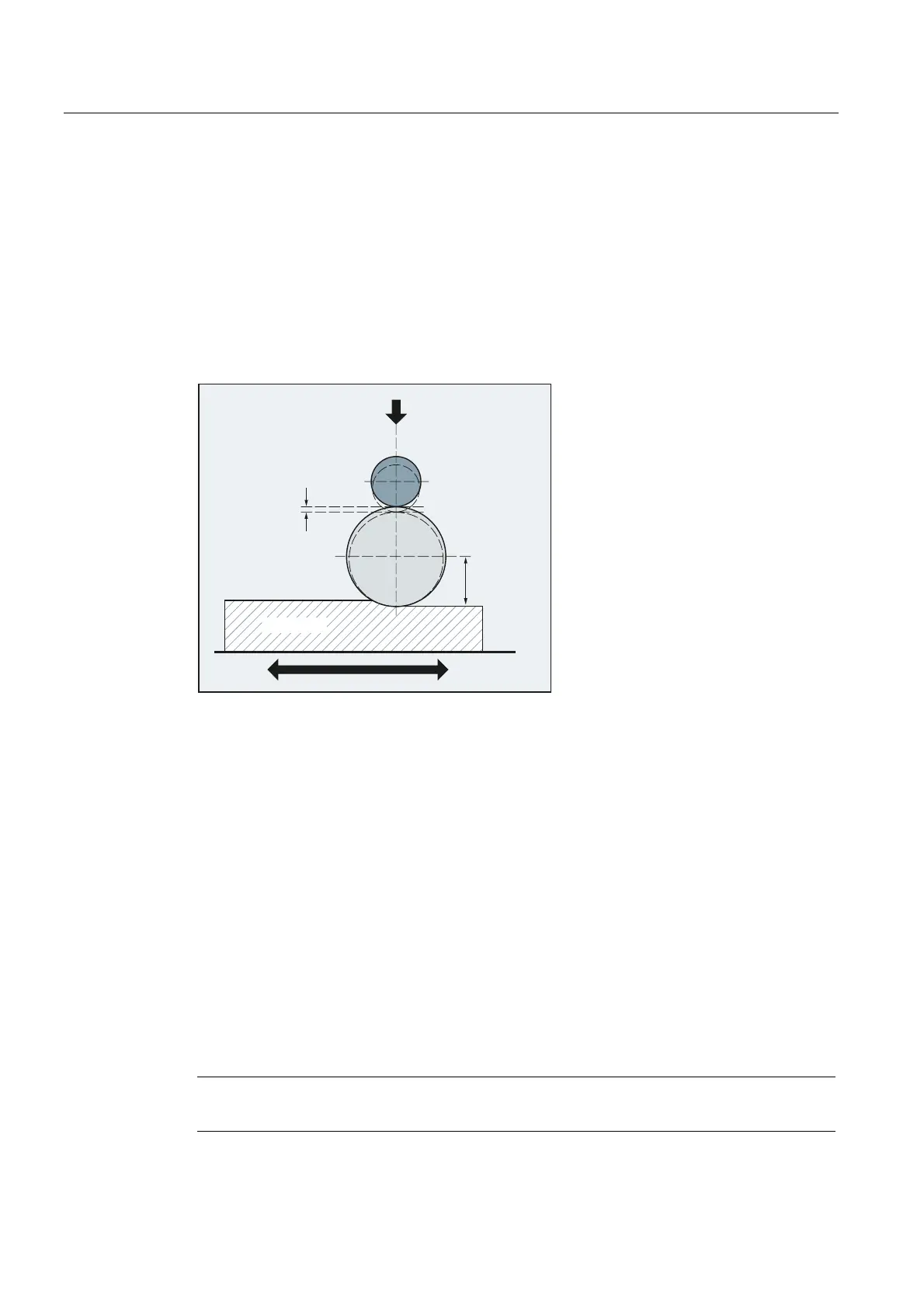

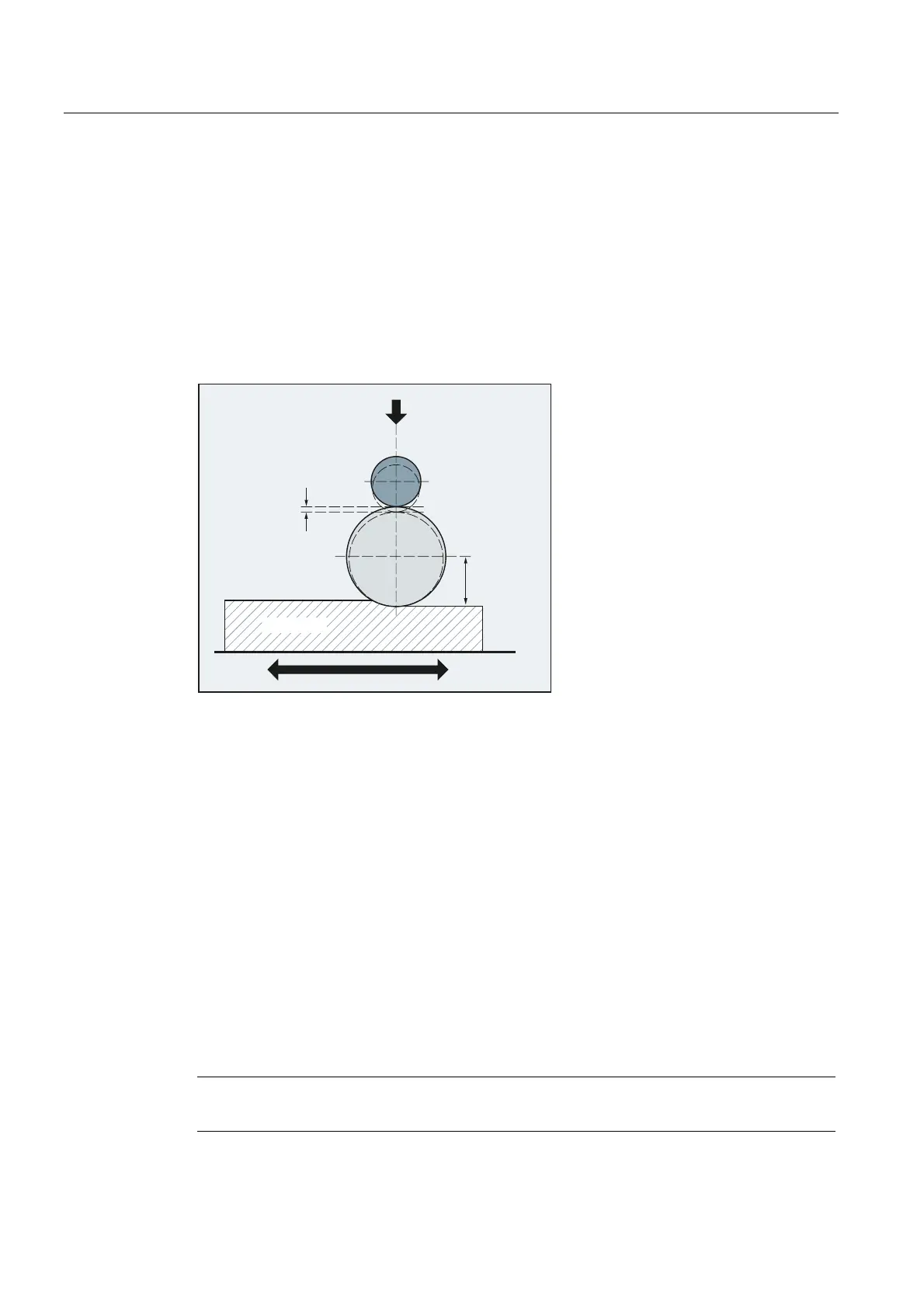

An application example is CD dressing, where the grinding wheel is dressed in parallel to

machining.

'UHVVLQJUROO

'UHVVLQJDPRXQW

:RUNSLHFH

*ULQGLQJGLVF

OHQJWK

WREH

FRUUHFWHG

The tool length offset can be changed from the machining channel or a parallel channel

(dresser channel).

The online tool offset is written using various functions dependent on the timing of the

dressing process:

● Continuous write, non-modal (

PUTFTOCF)

With

PUTFTOCF, dressing is carried out at the same time as machining.

The tool offset is changed continuously in the machining channel according to a

polynomial function of the first, second or third order, which must have been defined

previously with

FCTDEF.

PUTFTOCF is always non-modal; in other words, it takes effect in the subsequent traversing

block.

● Continuous write, modal:

ID=1 DO FTOC (see "Online tool offset (FTOC) (Page 589)")

● Discrete write (

PUTFTOC)

With

PUTFTOC, dressing is not carried out at the same time as machining from a parallel

channel. The offset value specified with

PUTFTOC takes effect immediately in the

destination channel.

Note

Online tool offset can be applied only to grinding tools.

Loading...

Loading...