Rockwell Automation Publication MOTION-UM002E-EN-P - June 2016 67

Configure an Articulated Independent Robot Chapter 4

Identify the Work Envelope for a Delta Three-dimensional Robot

The work envelope is the three-dimensional region of space that defines the

reaching boundaries for the robot arm. The typical work envelope for a Delta

robot can be described as looking similar to plane in the upper region, with

sides similar to a hexagonal prism and the lower portion similar to a sphere. For

more detailed information regarding the work envelope of your Delta three-

dimensional robot, see the documentation provided by the robot

manufacturer.

We recommend that you program the robot within a rectangular solid defined

inside the robots work zone. The rectangular solid can be defined by the

positive and negative dimensions of the X1, X2, X3 virtual source axes. Be sure

that the robot position does not go outside the rectangular solid. You can

check the position in the event task.

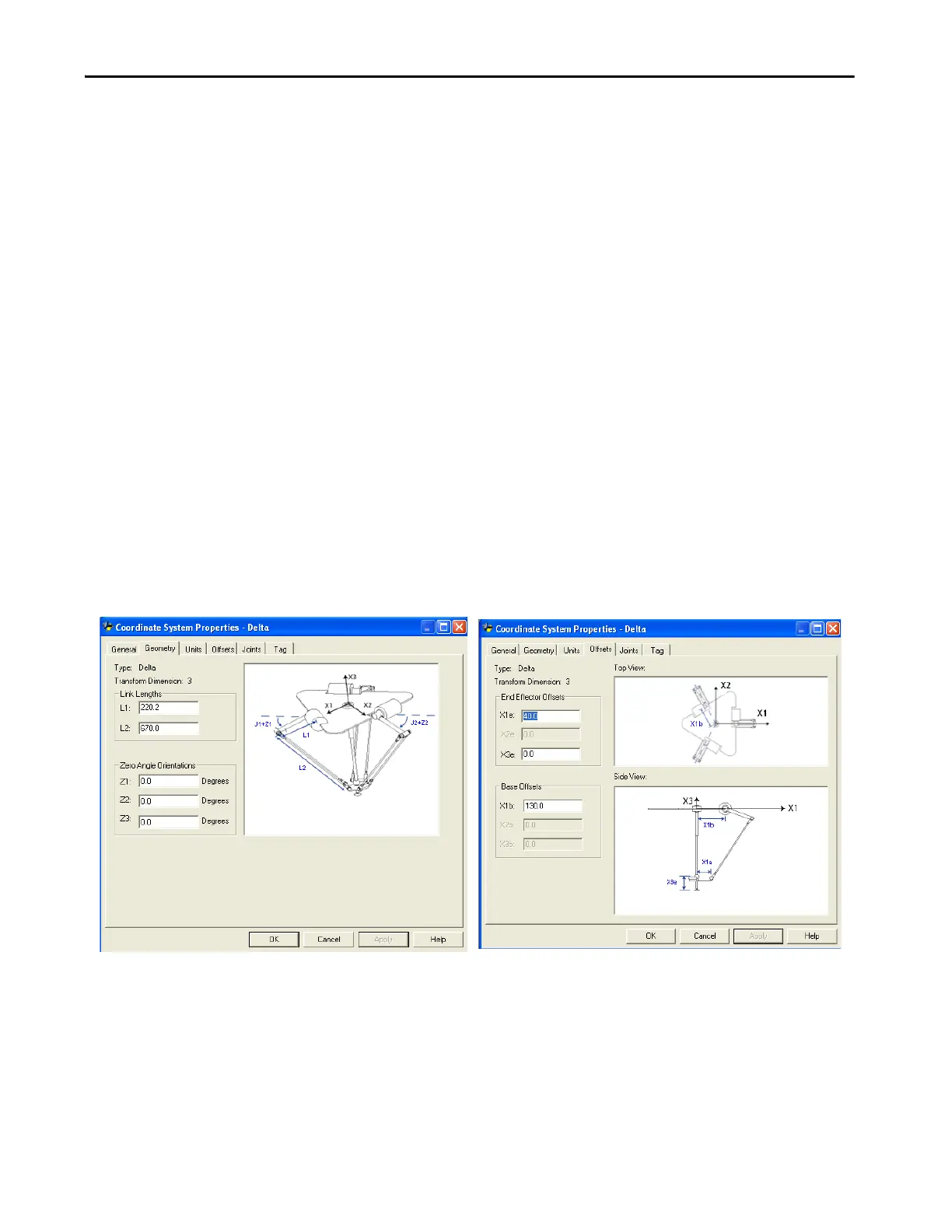

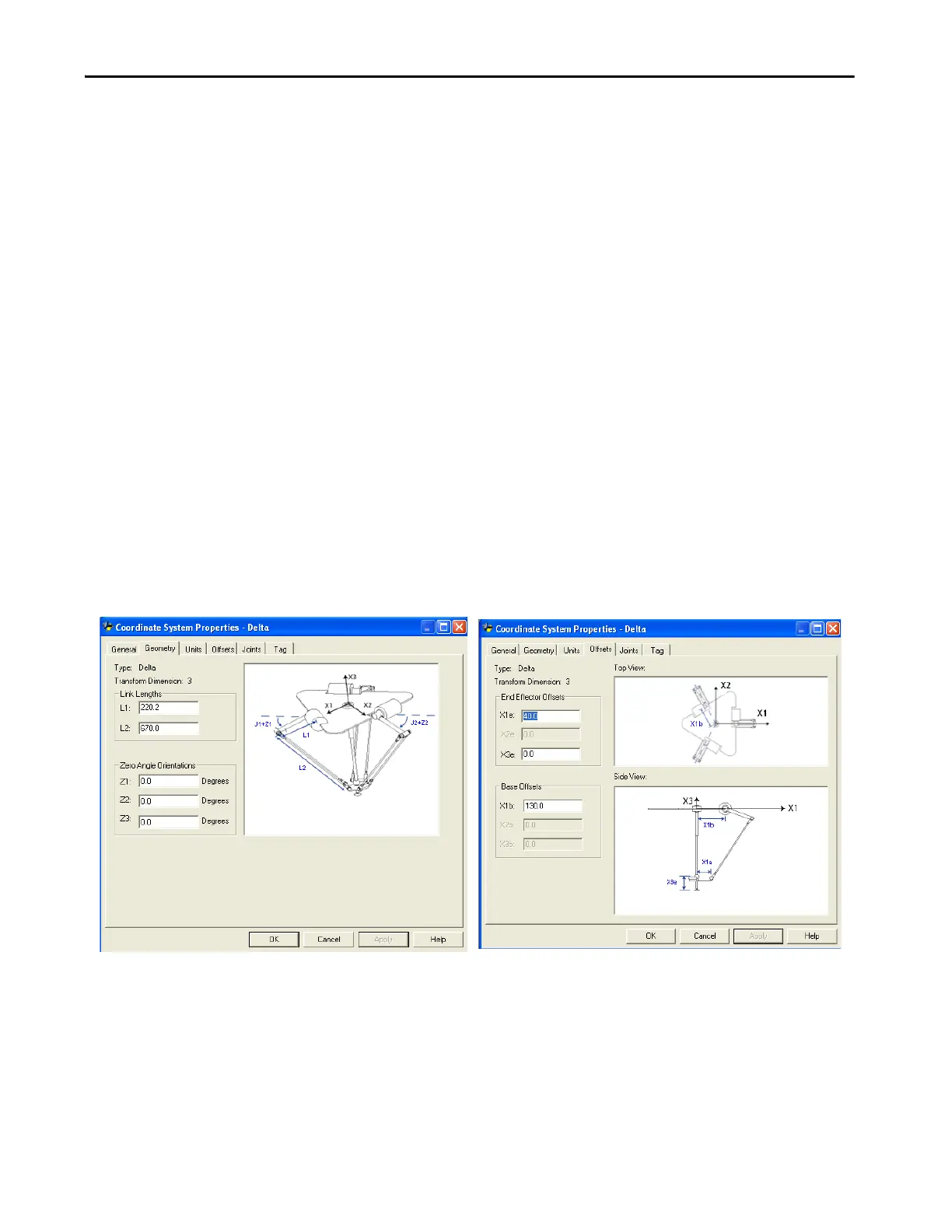

To avoid issues with singularity positions, Logix Designer application

internally calculates the joint limits for the Delta robot geometries. When an

MCT instruction is invoked for the first time, the maximum positive and

maximum negative joint limits are internally calculated based upon the link

lengths and offset values entered on the Geometry and Offsets tabs of the

Coordinate System Properties dialog.

Figure 20 - Delta Three-dimensional Configuration Systems Properties Dialog - Geometry and

Offsets Tabs

During each scan, Logix Designer application evaluates the joint positions in

the forward and inverse kinematics routines to be sure that they do not violate

the computed maximum positive and maximum negative joint limits.

Loading...

Loading...