80 Rockwell Automation Publication MOTION-UM002E-EN-P - June 2016

Chapter 4 Configure an Articulated Independent Robot

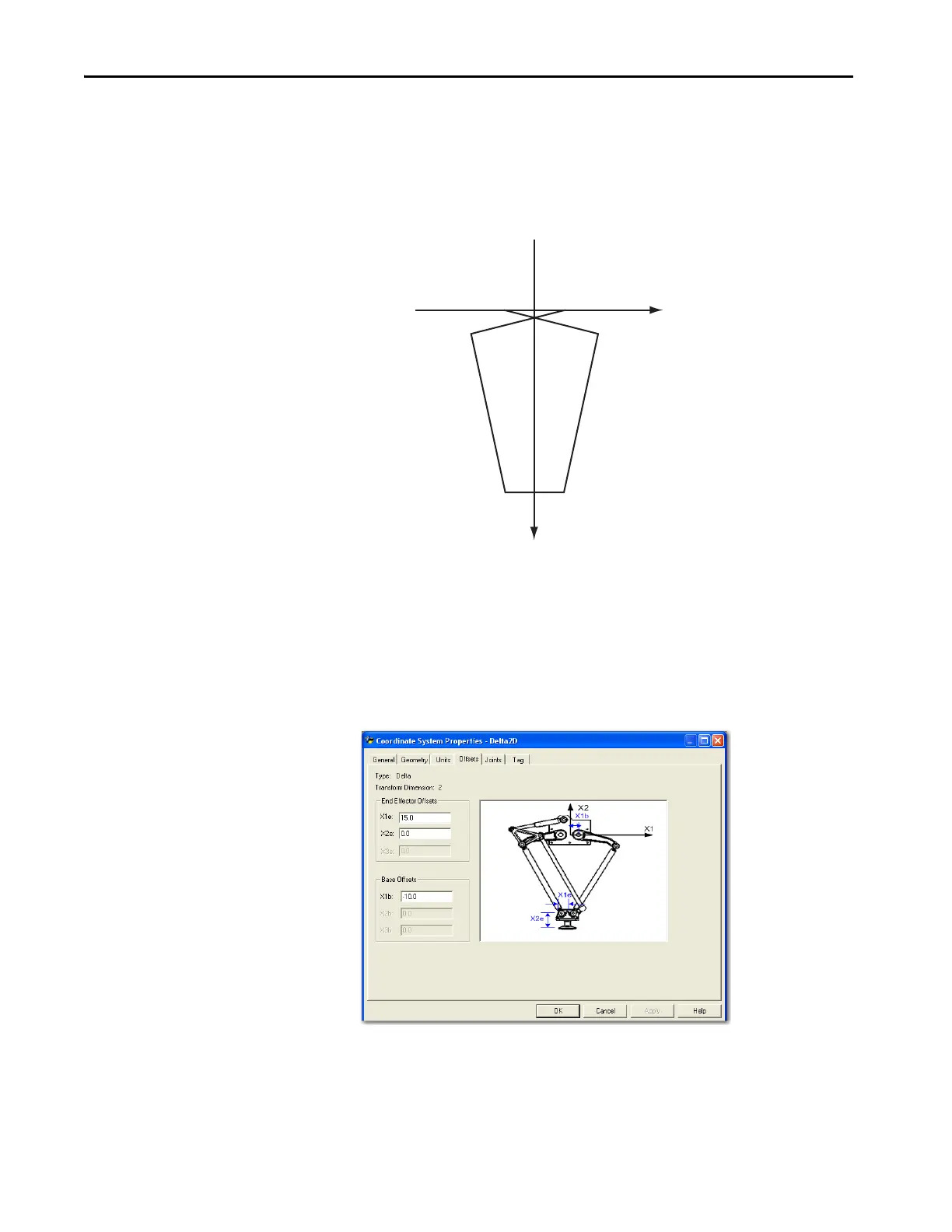

Configure a Delta Robot with a Negative X1b Offset

Beginning with version 17 of the application, you can use negative offsets for

the X1b base offset on both 2D and 3D delta geometries. For example, a

mechanical 2D delta robot that uses a negative X1b offset has a mechanical

configuration like the one shown here.

The base offset X1b is the value equal to the distance from the origin of the

robot coordinate system to one of the actuator joints. In the previous figure,

one of the actuator joints (P1), is on the negative side of X1. Therefore, the

base offset X1b is measured to be a value of -10 units from the origin of the

coordinate system (X1 - X2 intersection) to P1.

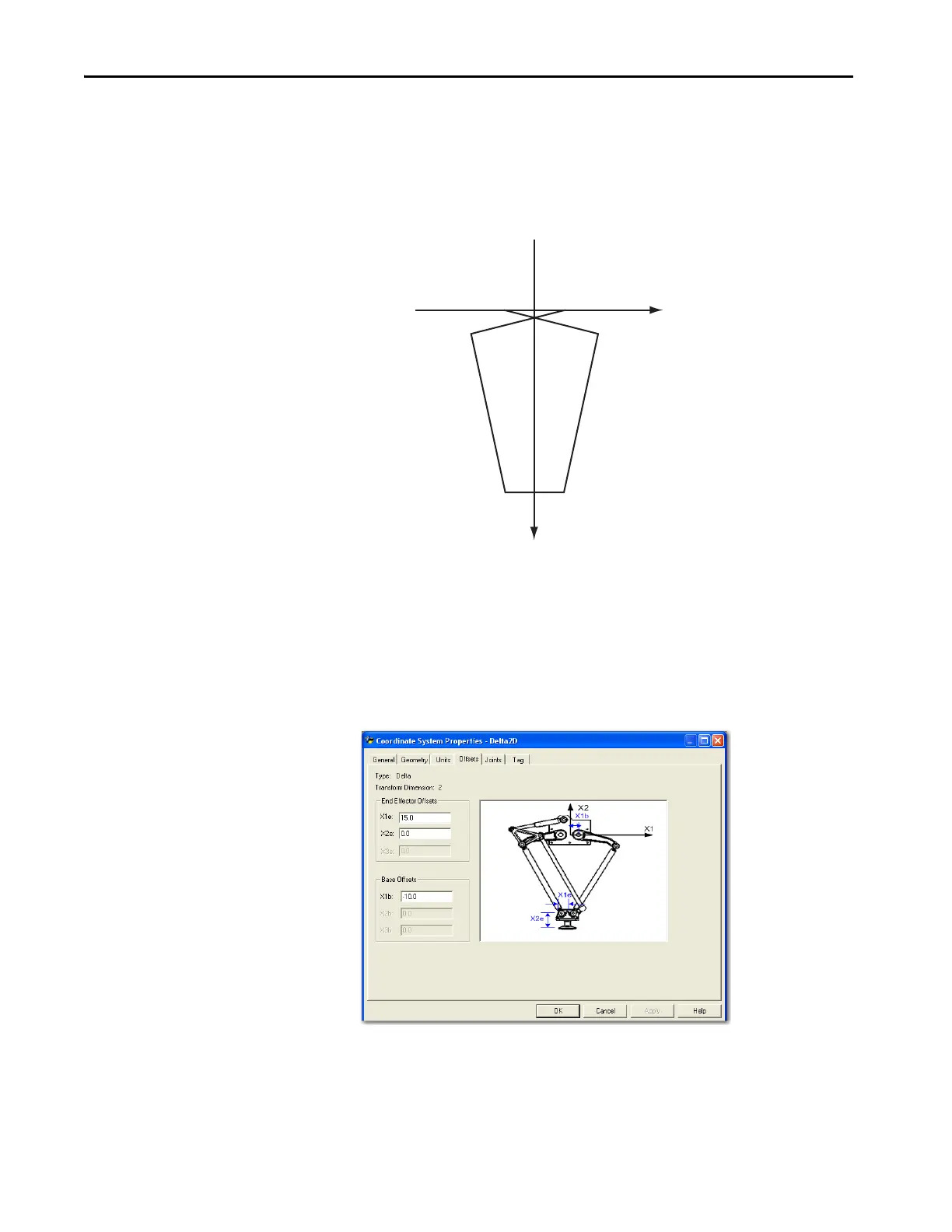

The Logix Designer application coordinate system configuration for the offset

tab used with the example in the previous figure is shown here.

This negative offset description also applies for Delta 3D and SCARA-Delta

Configurations.

+X1

+X2

X1eX1e

L2 L2

L1 L1

P1 P2

-X1b

-X1b

L1 = 50.0 units

L2 = 80.0 units

X1b = -10 units

X1e = 15 units

Loading...

Loading...