Emergencies

Important information about wheel bolts

F

act

ory-fitted rims and wheel bolts are spe-

cially matched during construction. There-

fore, if different rims are fitted, the correct

wheel bolts with the right length and heads

must be used. This ensures that wheels are

fitted securely and that the brake system

functions correctly.

In certain circumstances, you should not

even use wheel bolts from vehicles of the

same model.

WARNING

If the wheel bolts are not properly tight-

ened, they could come loose while driving

and cause an accident, serious injury and

loss of vehicle control.

●

Use only wheel bolts which correspond to

the rim in question.

●

Never use different wheel bolts.

●

Wheel bolts and threads should be clean,

free of oil and grease, and it should be pos-

sible to screw them easily.

●

To loosen and tighten wheel bolts, only

use the wheel wrench that came with the

car from the factory.

●

The wheel bolts should only be loosened

slightly (about one turn) before raising the

vehicle with the jack. Risk of accident!

●

Never apply grease or oil to wheel bolts or

to the wheel hub threads. Even if the bolts

have been tightened to the prescribed tor-

que, they could come loo

se while driving.

●

Never loosen the screwed joints of wheel

rims with bolted ring trims.

●

If wheel bolts are tightened below the

prescribed torque, the bolts and rims could

come loose while driving. If tightening tor-

que is too high, the wheel bolts or threads

can be damaged.

Raise the vehicle

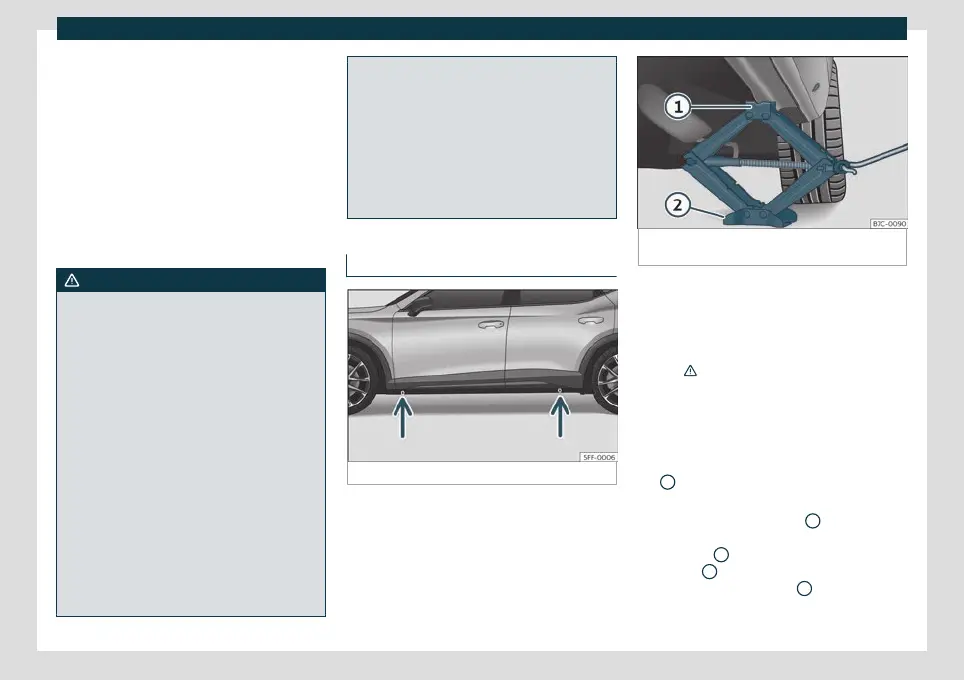

Fig. 38

Jack position points.

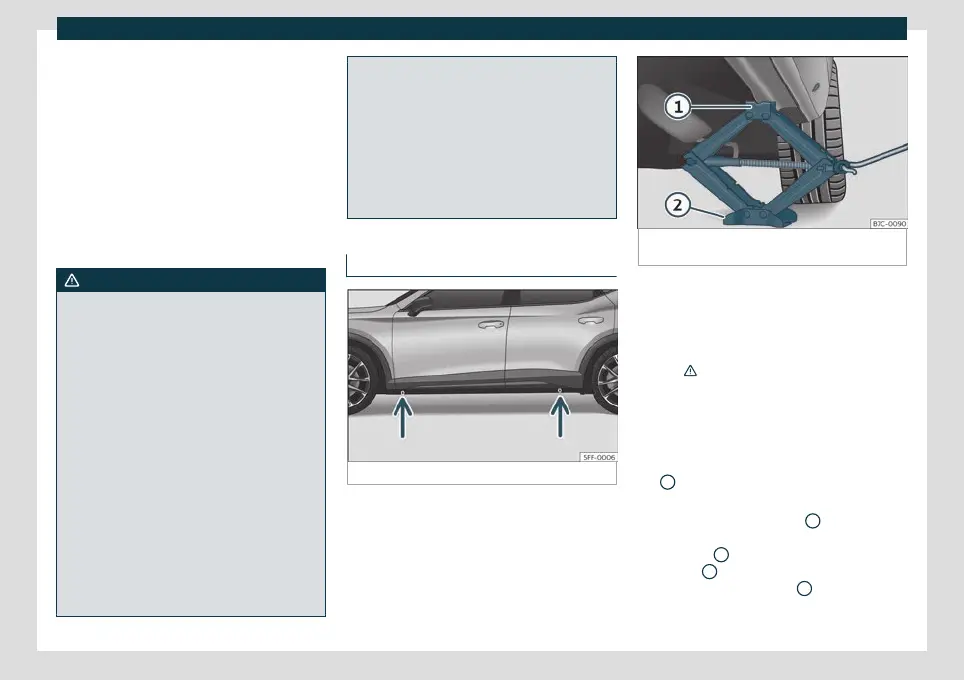

Fig. 39 Cross member: positioning the jack on the

vehicle.

●

Place the jack* (vehicle tools) on firm

gr

ound. If necessary use a lar

ge, strong

board or similar support. If the surface is slip-

pery (for example tiles) place the jack on a

rubber mat or similar to prevent it from slip-

ping

›››

.

●

Find the support point on the strut (sunken

ar

e

a) closest to the wheel to be changed

›››

Fig. 38.

●

Turn the jack* crank handle, located below

the strut support point, to raise it until the

tab

1

›

›

›

Fig. 39 is below the housing provi-

ded.

●

Align the jack* so that tab

1

“grips” onto

the housing pr

o

vided on the strut and the

mobile base

2

is resting on the ground. The

base plat

e

2

should fall vertically with re-

spect t

o the support point

1

.

●

Continue turning the jack* until the wheel

is slightly lift

ed off the gr

ound.

48

Loading...

Loading...