Chapter 7: Repair Procedures

Right Rail Assembly Repair Procedures

7-24 Service Manual

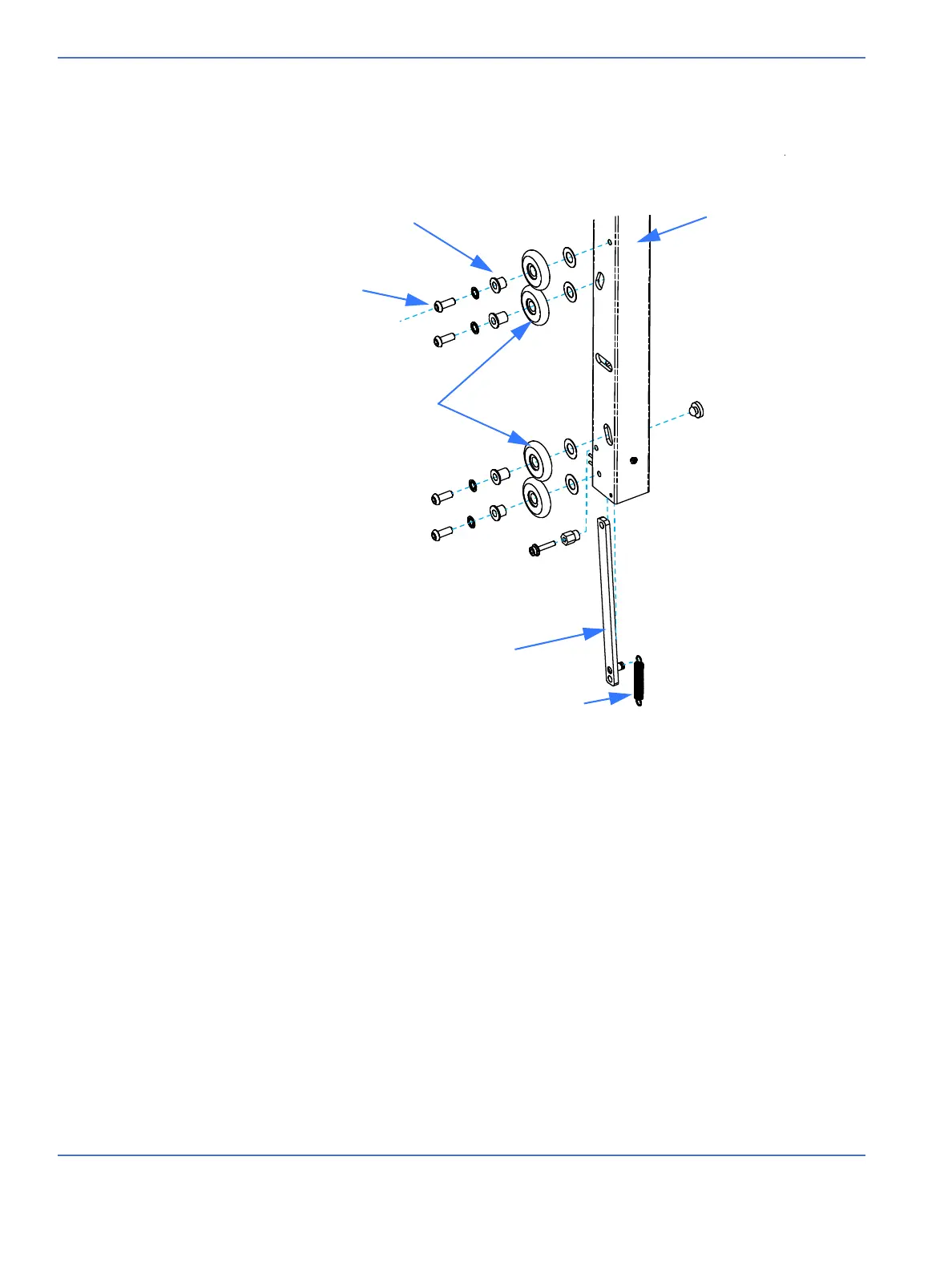

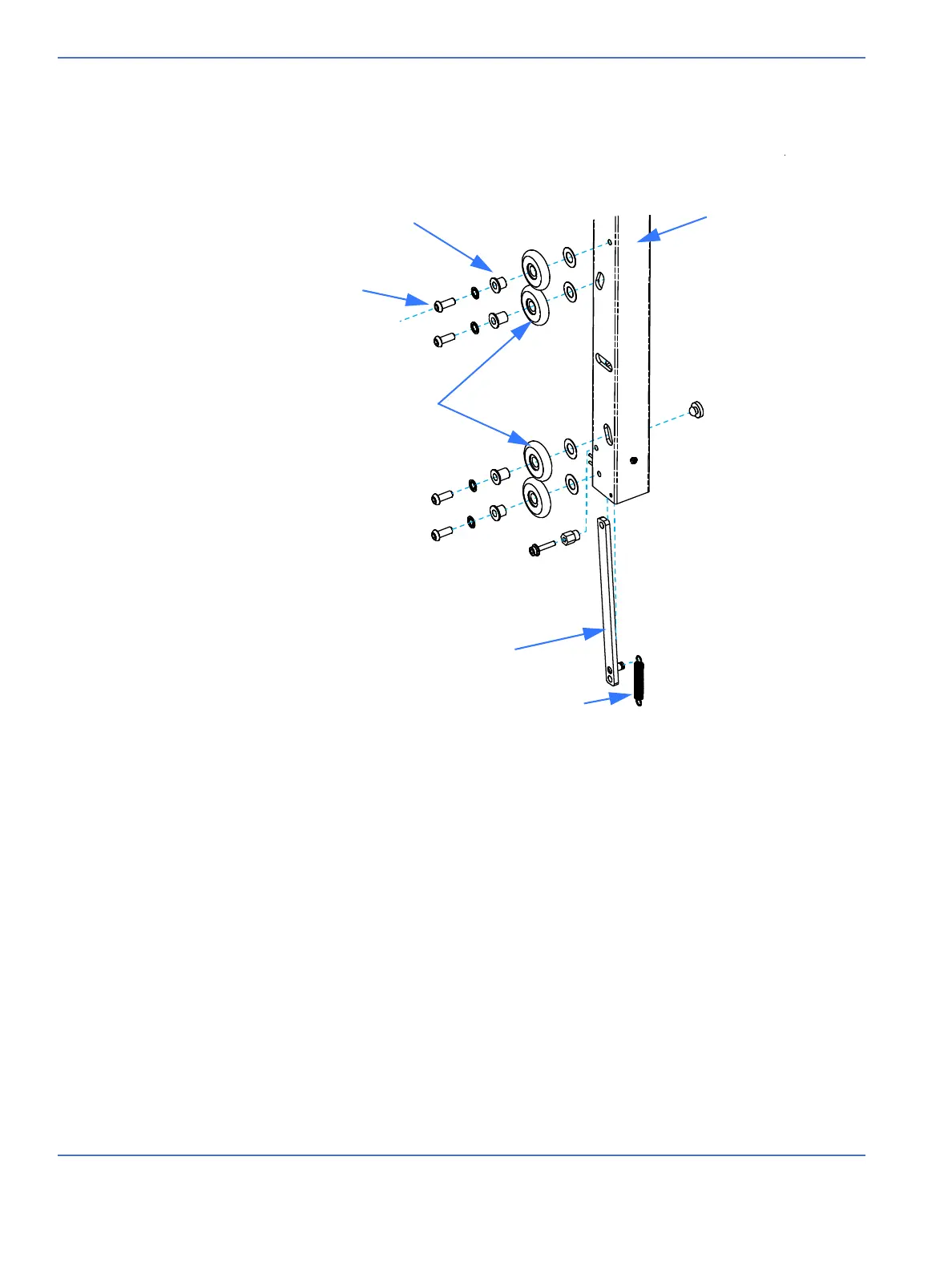

7.4.3.2 Replacing Rollers and Tension Springs

Refer to “Figure 7-26 Rollers and Tensioning Spring”.

1. The rollers can be removed one at a time by removing the screw (4 mm hex key) at their hub and pulling

off the roller and bearing. When reinstalling, torque the screws to 45 in. lbs (reference).

2. To replace the roller tensioning spring, first use needle nose pliers to pull the tension spring off the roll

pin at the end of the lift rail. Then take off the 2 center rollers and slide the tensioning plate out of the lift

rail. Remove the old spring.

3. Reinstall the 2 center rollers. Use a hex key in the center access slot to lift the tensioning plate up so

that you can screw the rollers into the holes in the plate. Torque rollers screws to 45 inch lbs (reference).

4. Using pliers, pull the tensioning spring up onto the roll pin at the end of the rail.

7.4.3.3 Separating the Lift Rail from the Belt Channel

Refer to “Figure 7-25 Right Rail Disassembly”.

1. If you can access the screw head through the access hole in the lift rail go to step 2. If you can not

access the screw, push the lift rail and the belt channel together and lift the belt block up past the roll

pin so you can see the screw head through the access hole in the lift rail.

FIGURE 7-26. Rollers and Tensioning Spring

Bearing

Roller mounting screw

Center rollers

Tensioning plate

Roller tensioning spring

Lift rail

Loading...

Loading...