Part Options 252

Instructions

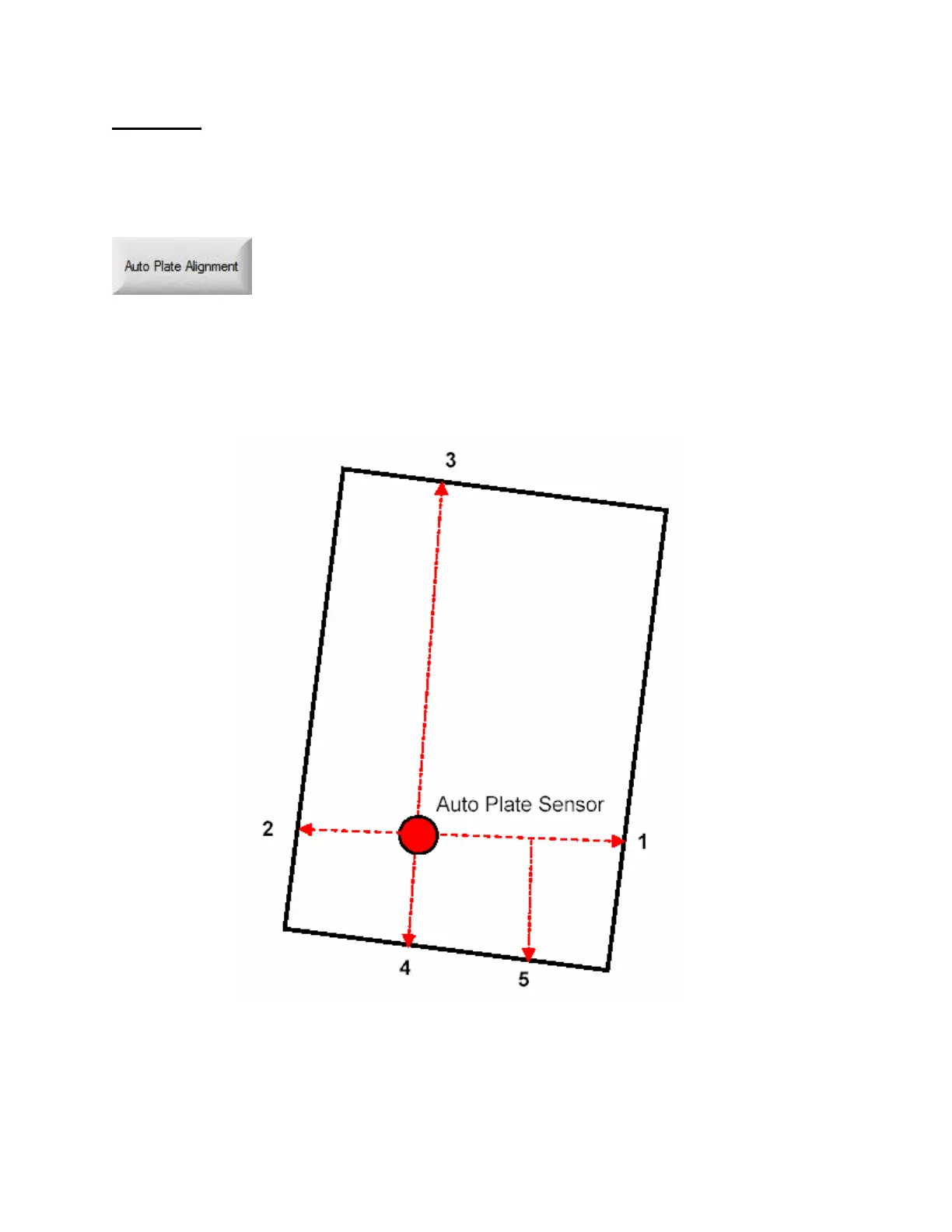

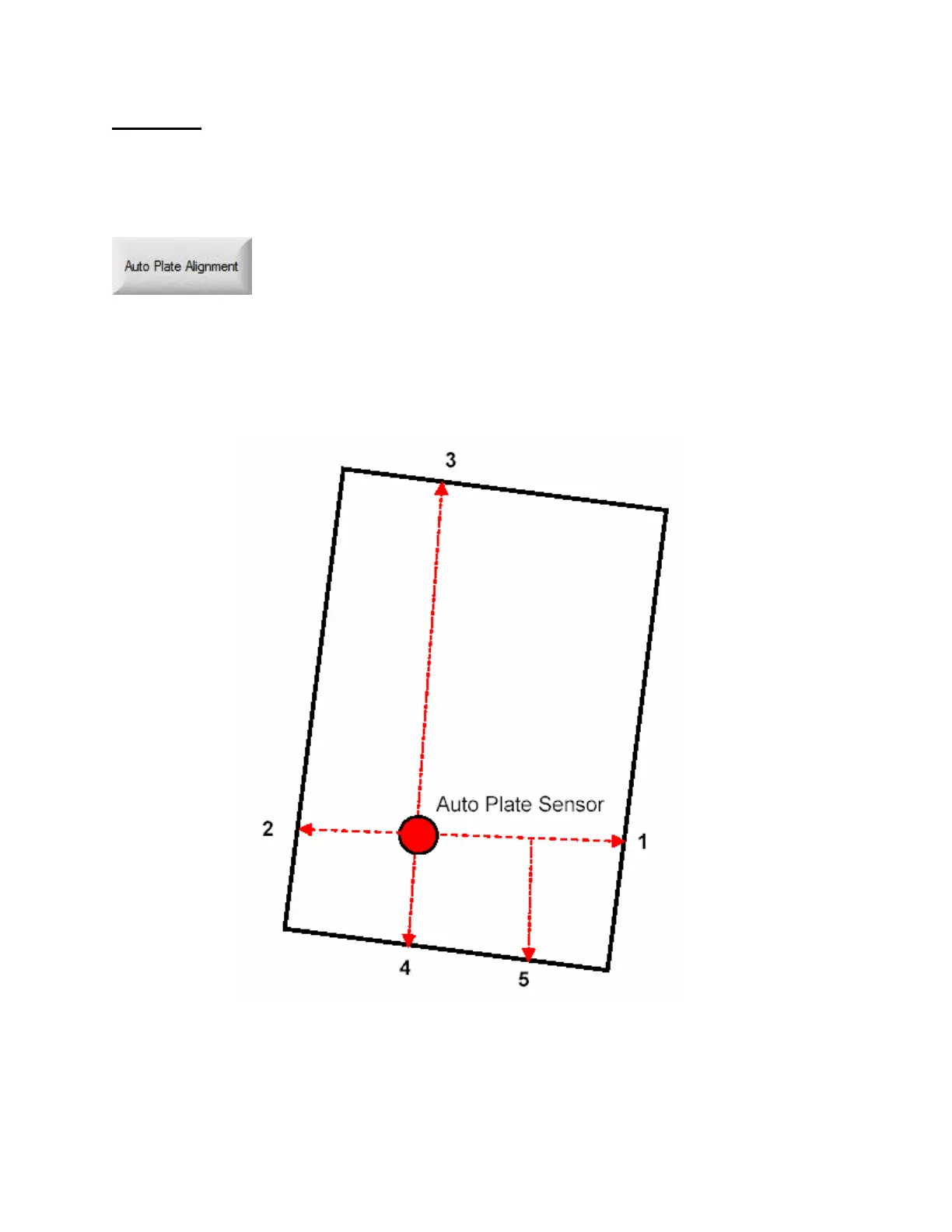

1) To start the Automatic Plate Alignment function, manually position the Plate Sensor above the

plate. At this point the Auto Plate Align Sensor Input should be active.

2) Press the Automatic Plate Align Soft key at the Part Options screen.

3) A motion sequence will then be executed to detect the right, left, top, bottom and bottom right

skew reference edges of the plate. In each case, the control will move to the outward edge of the

plate until the sensor detects the edge of the plate (off state). The control will then reverse

motion at a med speed until the sensor again becomes active then moves off at a slow speed.

This position is recorded as the respective reference point. Motion continues until all five points

are detected.

4) Upon completing detection of the five reference points, the control will then position the Plate

Sensor (if no tool offset used) or the torch (if a tool offset is used) to the start point of the part

program. Scrap Clearance (from the Align screen) and Start Corner (from the Align screen) will

also be executed in the final position move, and will set the plate size to the detected dimension.

Loading...

Loading...