3.4 Control of common rail system

(CRS) engine

The following

items are controlled by the engine ECU

as control for a common rail system engine.

1. Fuel injection quantity control

The amount of fuel injected is determined using

standard injection volume calculated based on

engine state and operating conditions.

A calibration value is added to this information

through parameters such as coolant temperature,

intake air temperature, and intake air pressure.

2. Fuel injection timing control

The engine ECU controls injection timing through

start of energization of the injectors.

First the main injection timing is determined and

next other injection timing such as pilot injections

are set.

3. Fuel injection rate control

A pilot injection enables maintaining minimum initial

fuel injection rate.

This mitigates explosive initial combustion and

reduces NOx and noise.

4. Fuel injection pressure control

Based on engine load (final injection volume and

engine speed), the engine ECU calculates the set

fuel injection pressure.

Calculated data is used to control the volume

supplied by the supply pump as well as the fuel

pressure in the rail.

3.5 Fuel tank

3.5.1 Outline of fuel tank

The fuel tank stores fuel.

3.5.2 Structure of fuel tank

The fuel tank is made up of a tank body and fuel inlet

opening.

3.5.3 Function of fuel tank

The fuel tank stores fuel.

A float

is generally provided in the tank to show the

amount of fuel remaining.

This float detects float liquid surface position and sends

a signal to a meter on the operator panel.

3.5.4 Specification of fuel tank

Tank volume is different depending on the model

equipped on.

Check the

specifications of the model equipped on for

details.

3.6 Water separator

3.6.1 Outline of water separator

The water separator removes the water included in the

fuel.

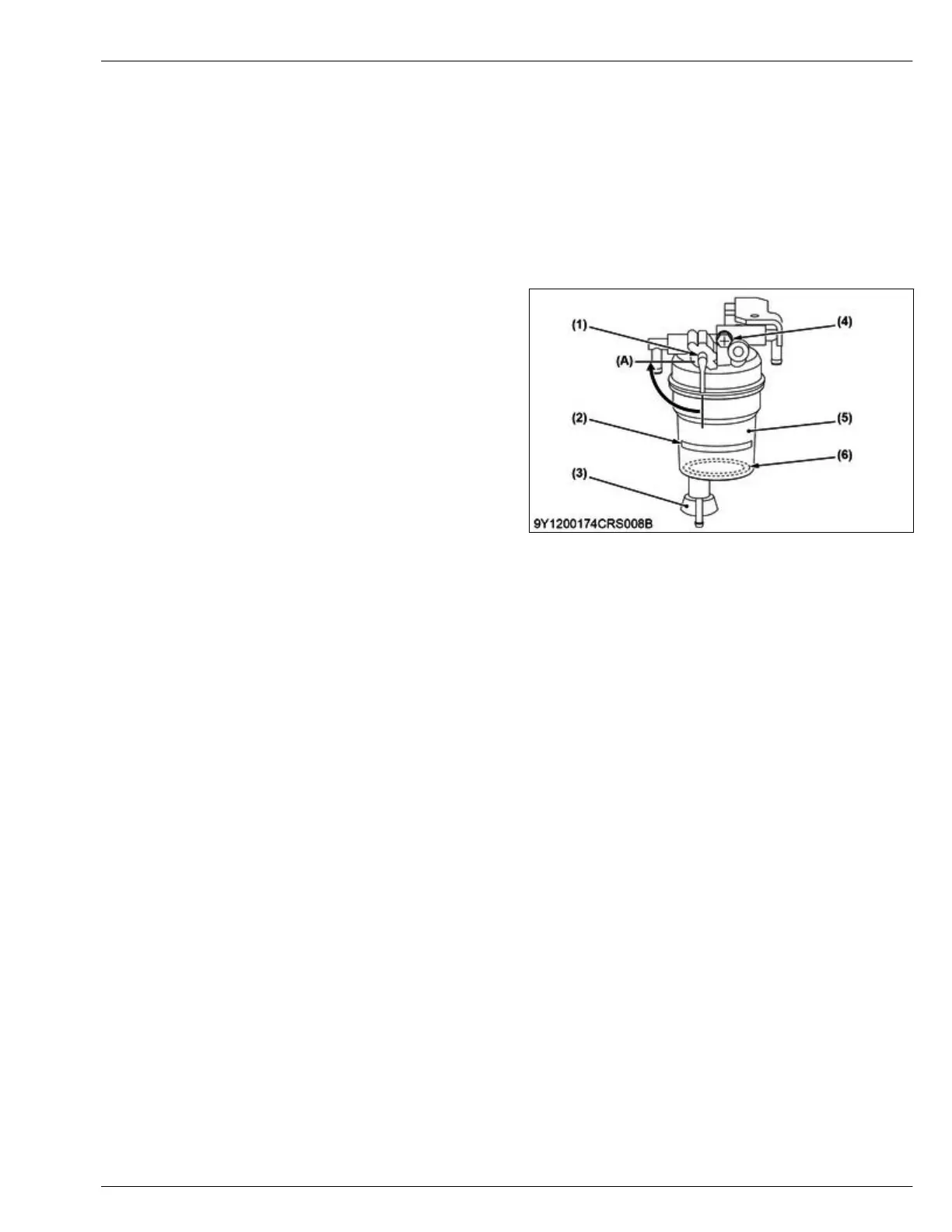

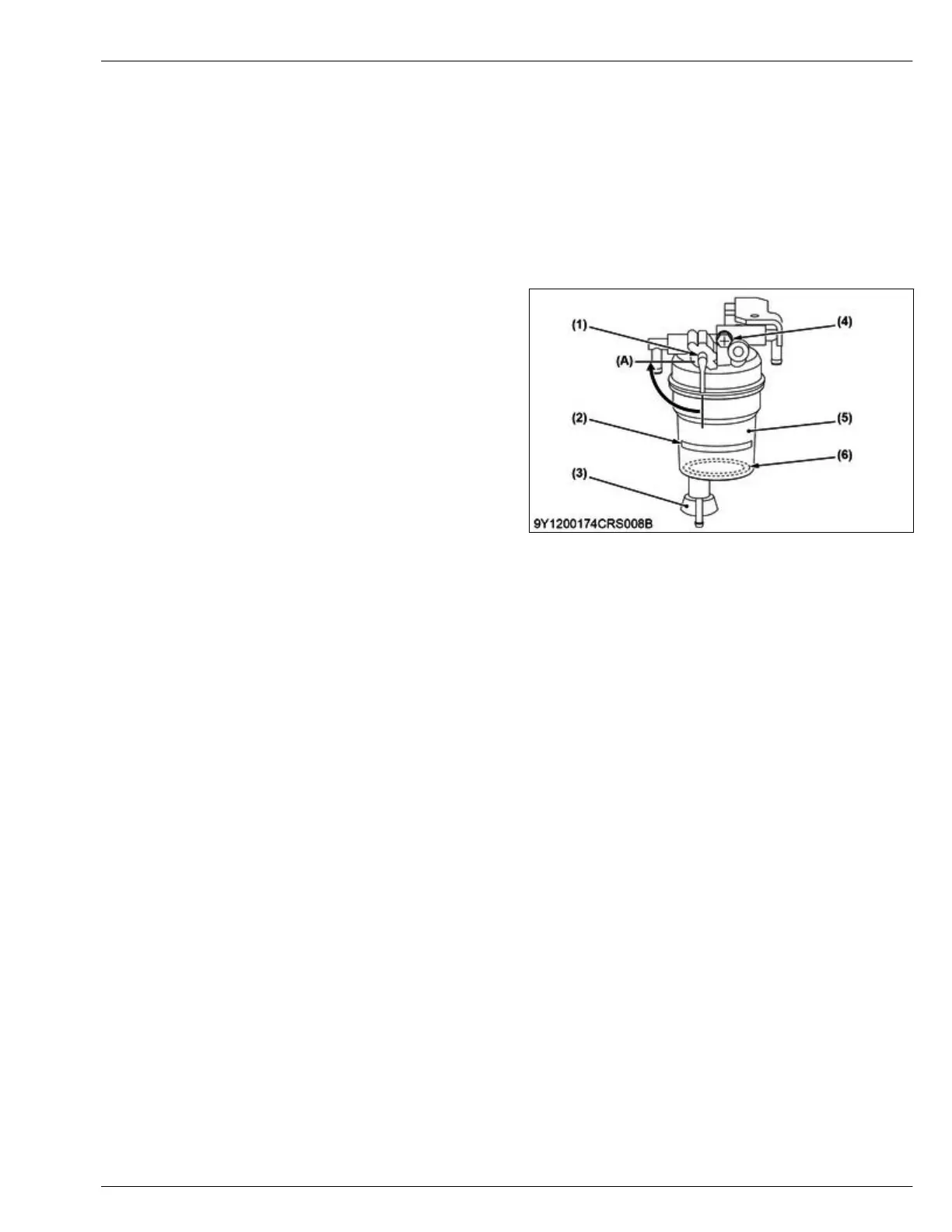

3.6.2 Structure of water separator (Type1)

The water separator (Type 1) is made up of the cup,

float, and water separator handle and the like.

(1) Water separator handle

(2) Line

(3)

Valve

(4) Screw

(5) Cup

(6) Float

(A) Close

3.6.3 Structure of water separator (Type2)

The water separator is made up of the separator body,

hand pump, and level sensor and the like.

The fuel flow direction of the water separator is set.

MECHANISM

3. Fuel system 4. ENGINE

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...