3. Clean

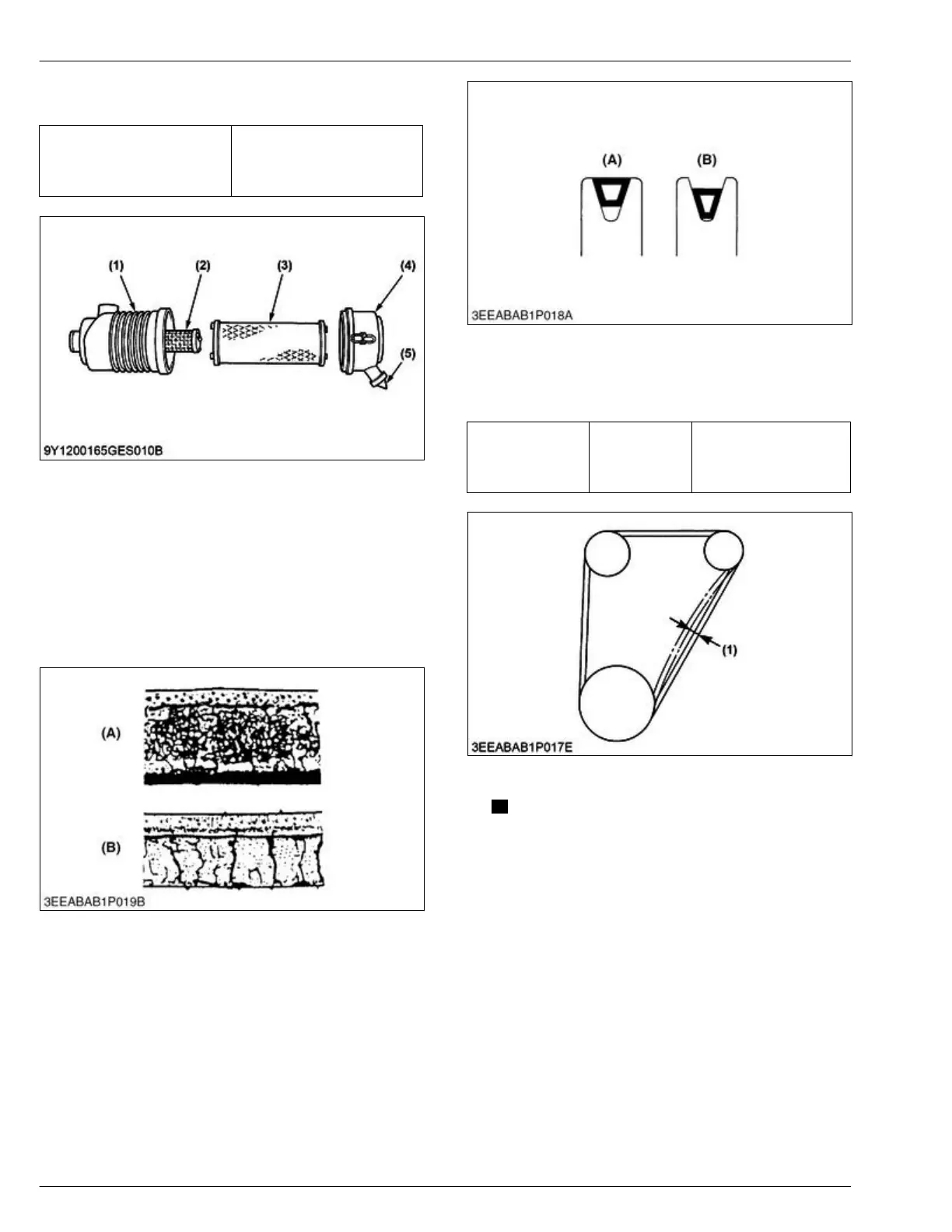

the inner side of the primary element (3) by

clean dry compressed air

.

Pressure of compressed air

Less than

205 kPa

2.1 kgf/cm

2

30 psi

(1) Air cleaner housing

(2)

Secondary element

(3)

Primary element

(4) Dust cup

(5) Evacuator valve

4. Install the removed parts.

4.2 Adjusting fan belt tension

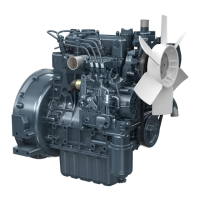

1. Check

that the fan belt is worn out and sunk in the

pulley groove or not.

•

If it is, replace it.

(A) OK (B) Wear

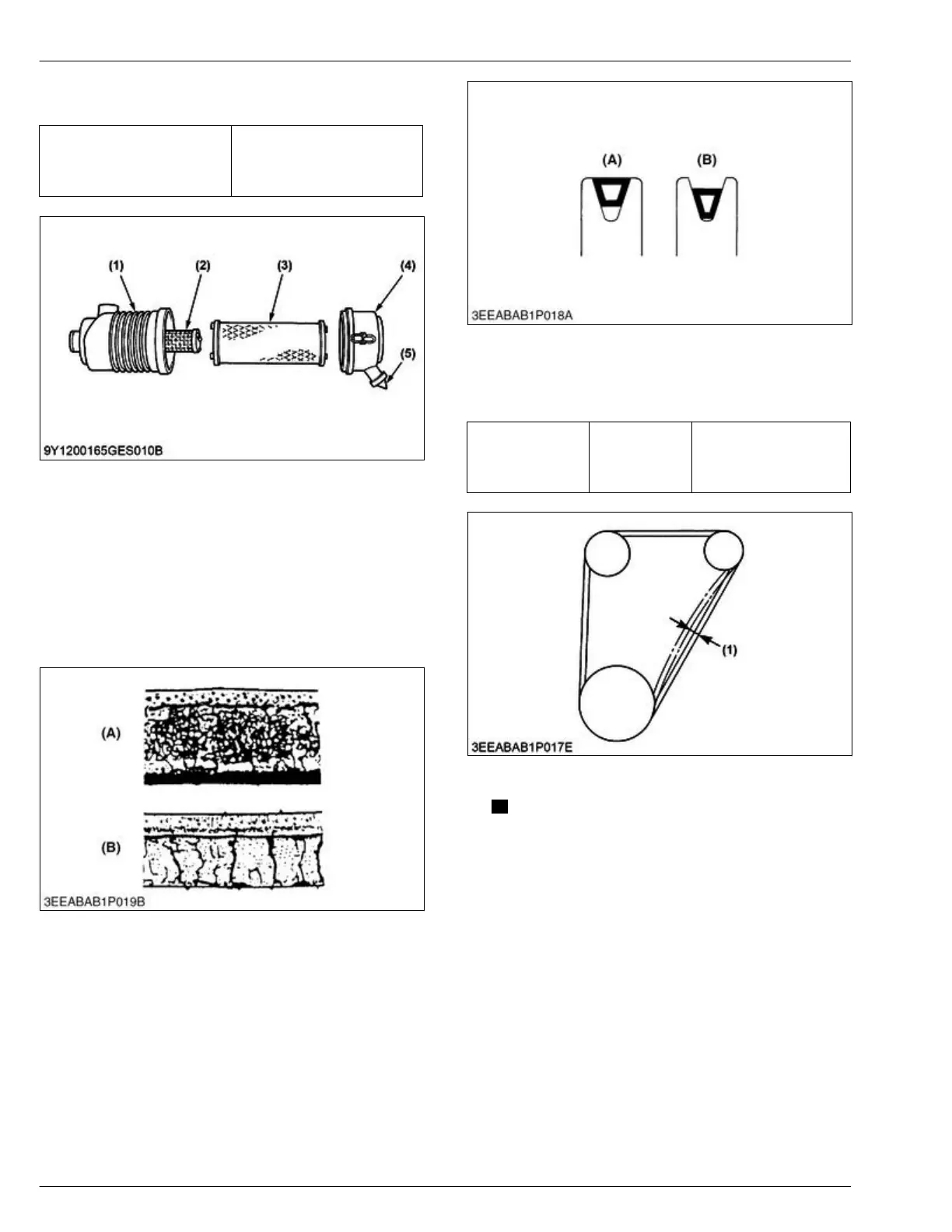

2. Push the belt halfway between the fan drive pulley

and alternator pulley at a specified force to measure

the deflection (1).

Deflection (1)

Service specifi-

cation

10.0 to 12.0 mm

0.394 to 0.472 in. in.

(under load of 98 N

(10 kgf, 22.1 lbf))

(1) Deflection

NOTE

• If the

measurement is out of the service

specifications, loosen the alternator

mounting screws and adjust its position.

4.3 Checking radiator hose and

clamp bands

1. Check that the radiator hoses (1), (2) are connected

correctly or not.

3.

MAINTENANCE

CHECK AND MAINTENANCE

4.Check points of every 250 hours

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...