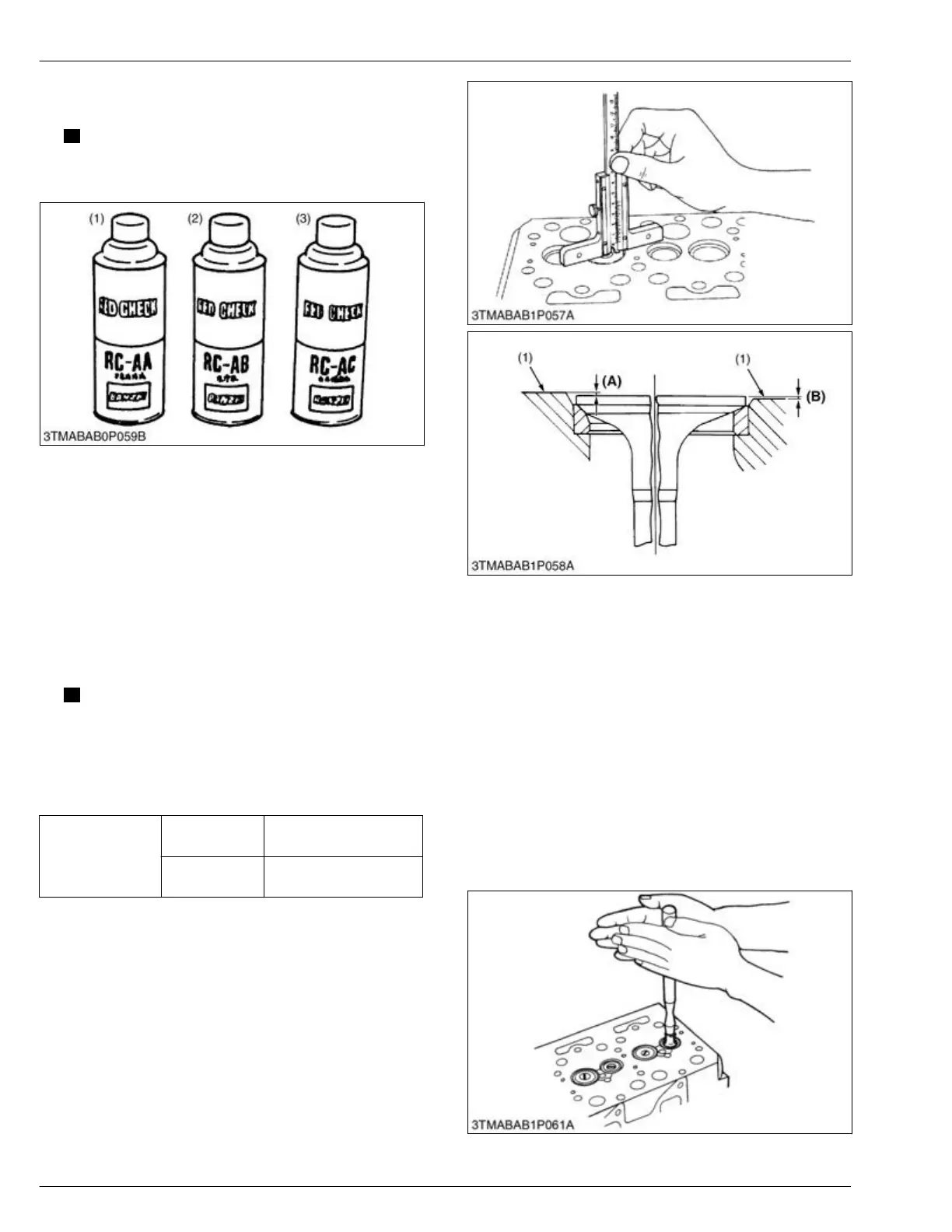

5. Apply

the white developer (3) on the cylinder head

surface.

NOTE

• If you

found a red flaw, replace the cylinder

head.

(1) Red permeative liquid

(2) Detergent

(3) White developer

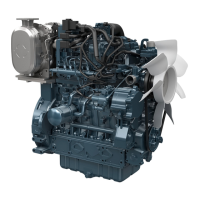

7.4 Checking valve recessing

Tools required

• Depth gauge

1.

Clean the cylinder head surface (1), valve face and

valve seat.

2. Set the valve into the valve guide.

3. Measure the valve recessing with a depth gauge.

NOTE

• If

the

measurement is more than the service

limit, replace the valve.

• If it stays more than the service limit after

you replace the valve, replace the cylinder

head.

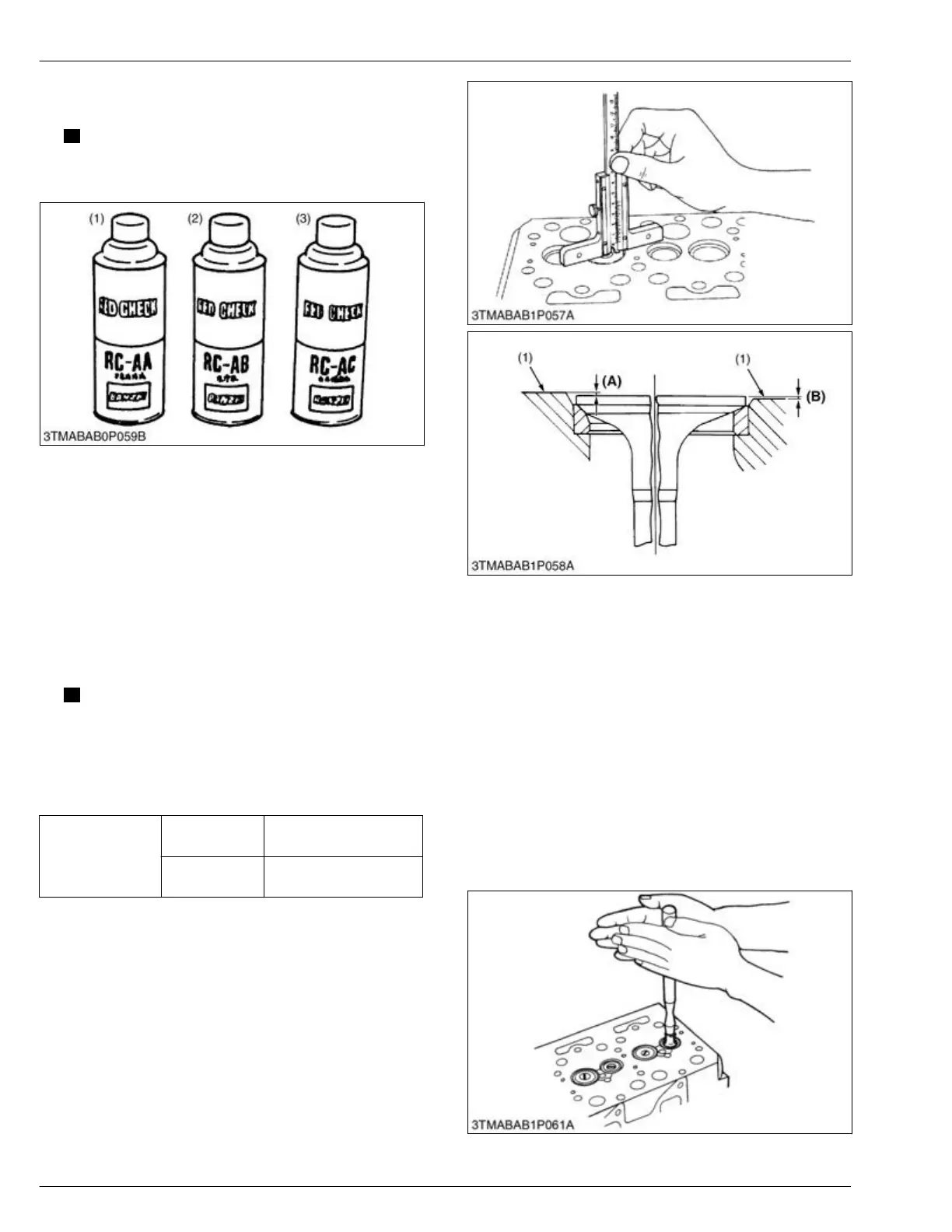

Valve recessing

Service specifi-

cation

0.65 to 0.85 mm

0.026 to 0.033 in.

Service limit

1.20 mm

0.0472 in.

(1) Cylinder head surface

(A) Recessing

(B)

Protrusion

7.5 Adjusting valve lapping

Tools required

• Compound

•

Valve lapping tool

• Prussian Blue

1. Apply the compound equally to the valve lapping

surface.

2. Put the valve into the valve guide. Lap the valve on

its seat with a valve lapping tool.

3. After you lap the valve, clean away the compound

and apply oil, then lap the valve again with oil.

4. ENGINE

SERVICING

7. Servicing

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...