6.6 Installing bearing case cover

IMPORTANT

• In case

of replacing the oil seal, install the oil

seal to the bearing case cover not to be tilted.

The seal should be flush with the cover.

• Before installing the bearing case cover / oil

seal assembly, lube the seal and install it not to

damage the seal.

NOTE

• Check the

side clearance of crankshaft after

assembling.

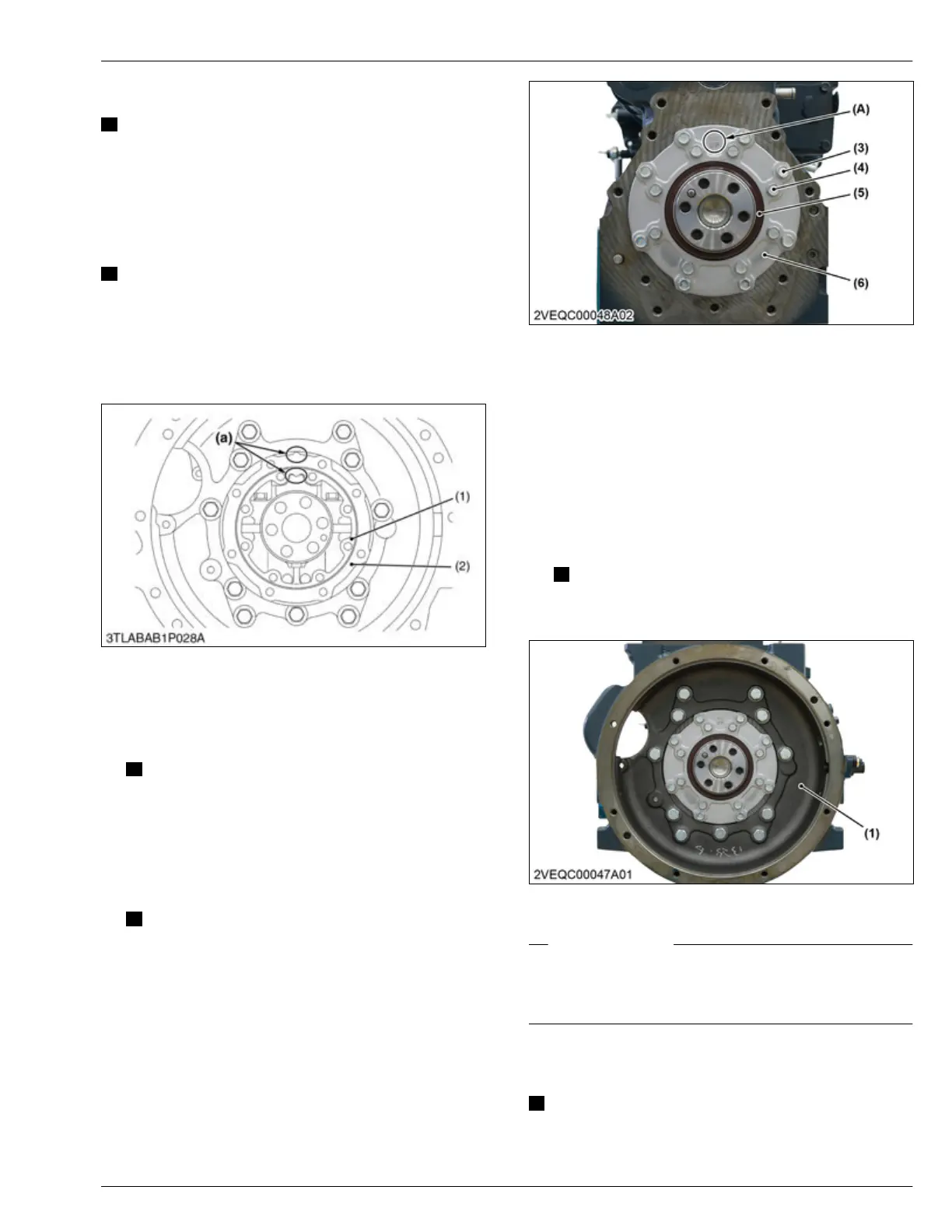

1. Attach the bearing case gasket (1) and the bearing

case cover gasket (2) in the correct position of

upside mark (a).

(1) Bearing case gasket

(2) Bearing case cover gasket

(a)

Upside mark

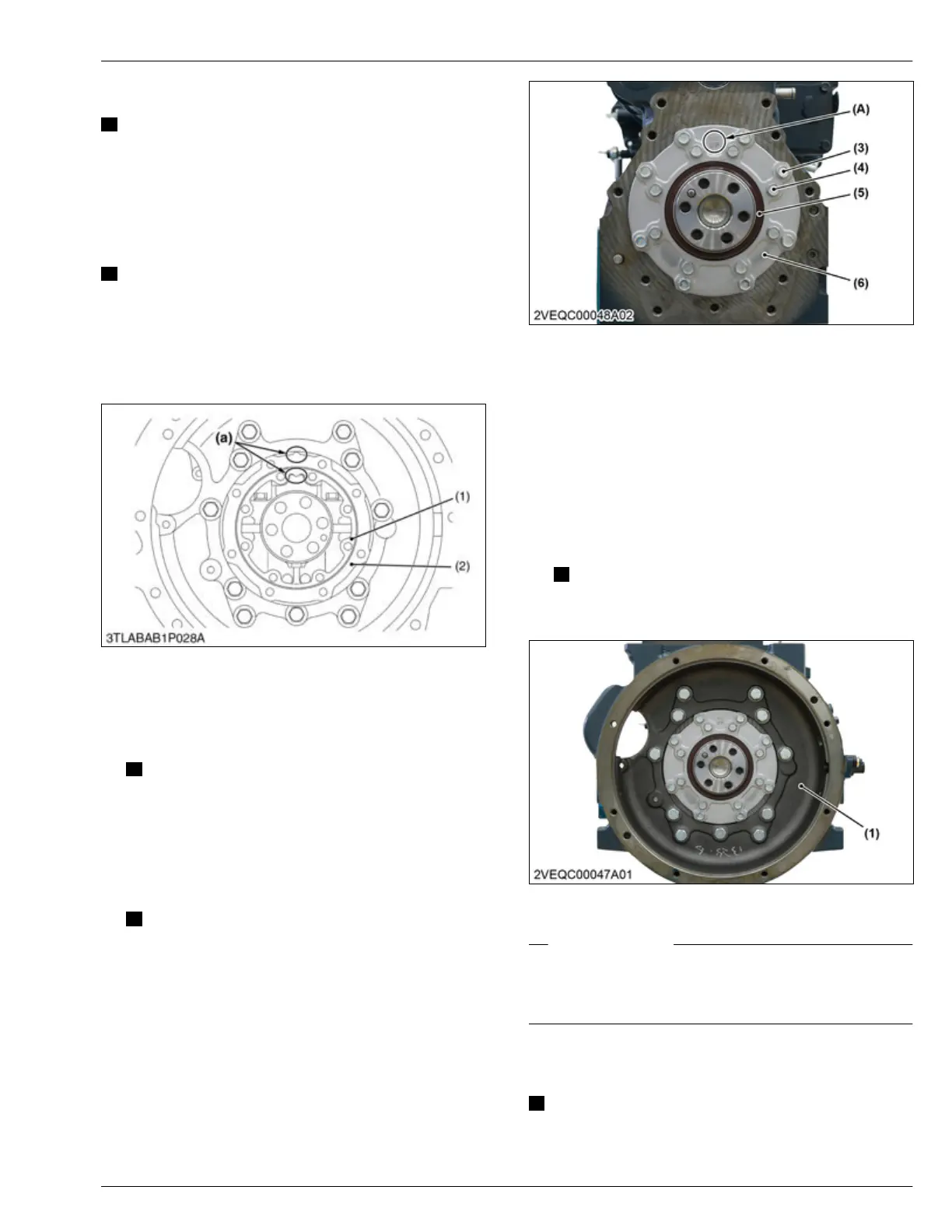

2. Put the casting mark [UP]

(A) of the bearing case

cover (6) upward, then install the bearing case

cover (6).

IMPORTANT

• The length

of inner mounting screws of

bearing case cover (4) and external

mounting screws of bearing case cover (3)

are different.

Make sure that you use the correct one at

the correct position.

NOTE

• Apply a

thin layer of engine oil to the oil seal

(5).

• Then install the oil seal not to come off the

lip.

(3) External mounting screw of

bearing case cover

(4) Inner mounting screw of

bearing case cover

(5)

Oil seal

(6) Bearing case cover

(A) Casting mark [UP]

3. Tighten the inner mounting screws of bearing case

cover

(4) and external mounting screws of bearing

case cover (3) to the specified tightening torque

with even force on the diagonal line.

6.7 Installing flywheel housing

1. Install the flywheel housing (1).

NOTE

• Tighten

the flywheel housing mounting

screws with even force on the diagonal line.

(1) Flywheel housing

RELATED PAGE

4.30 Measuring angular deviation between crankshaft

T.D.C. and crankshaft position sensor detected T

.D.C.

on page 4-112

6.8 Installing flywheel

IMPORTANT

• The

flywheel

is very heavy, so securely hold the

flywheel when installing.

SERVICING

6. Assembling 4. ENGINE

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...