2. Grind

the commutator with emery paper (#300) if it

is lightly worn.

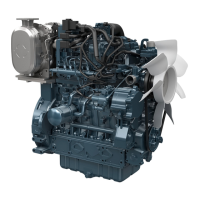

3. Measure the

commutator O.D. with an external

micrometer at several points.

NOTE

• If the

minimum O.D. is less than the service

limit, replace the armature assembly.

• If the difference of the O.D.'s more than the

service limit, correct the commutator on a

lathe to the service specification.

Commutator

O.D.

Service speci-

fication

D1803-CR-E4

D1803-CR-

TE4

D1803-CR-

TIE4

30.0 mm

1.18 in.

V2403-CR-E4

V2403-CR-

TE4

V2403-CR-

TE4BG

V2403-CR-

TIE4

35.0 mm

1.38 in.

Service limit

D1803-CR-E4

D1803-CR-

TE4

D1803-CR-

TIE4

29.0 mm

1.14 in.

V2403-CR-E4

V2403-CR-

TE4

V2403-CR-

TE4BG

V2403-CR-

TIE4

34.0 mm

1.34 in.

Difference of

O.D.'s

Service speci-

fication

Less than

0.02 mm

0.0008 in.

Service limit

0.05 mm

0.002 in.

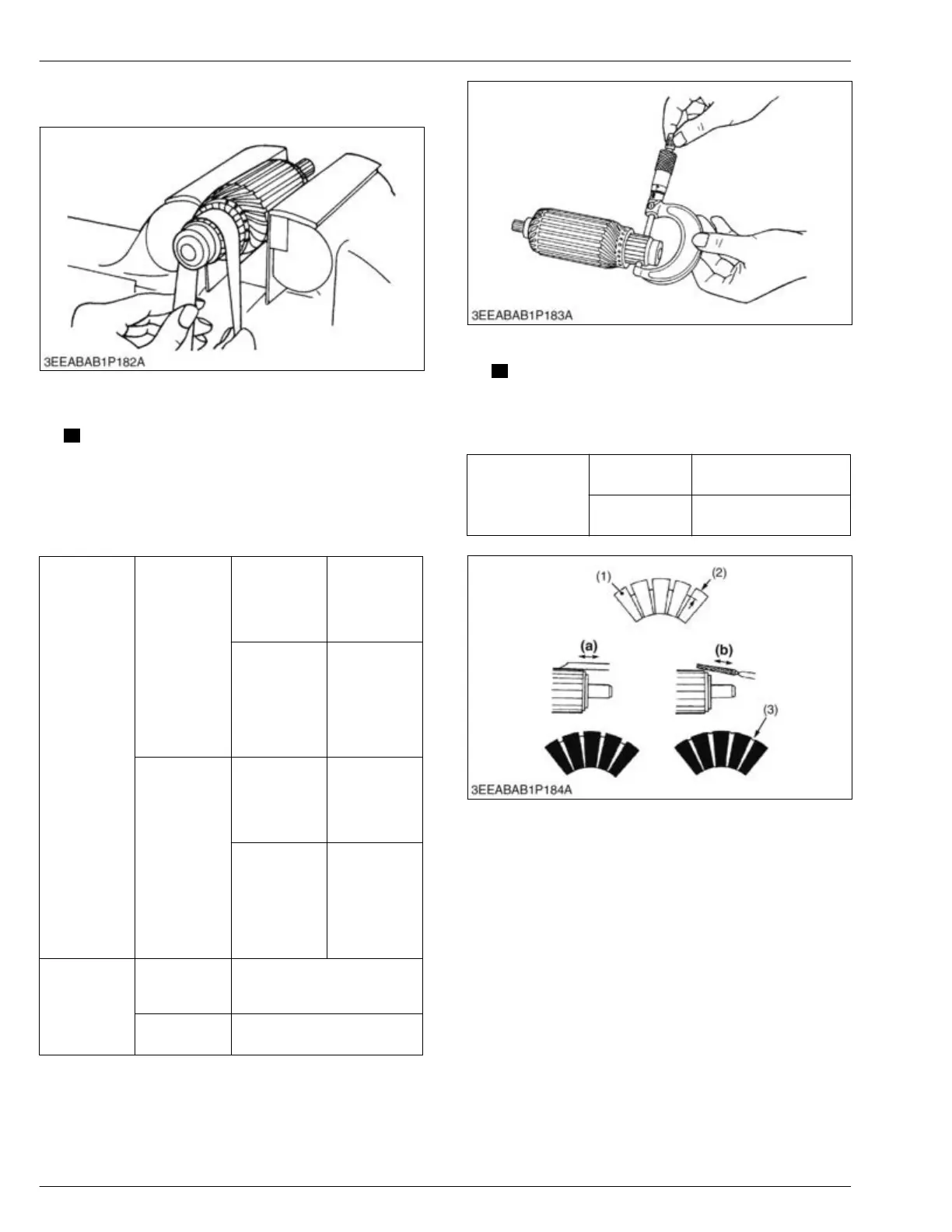

4. Measure the mica undercut.

NOTE

• If the

undercut is less than the service limit,

correct it with a saw blade. Chamfer the

segment edges.

Mica undercut

Service specifi-

cation

0.45 to 0.75 mm

0.018 to 0.029 in.

Service limit

0.20 mm

0.0079 in.

(1) Segment

(2) Depth of mica

(3)

Mica

(a) Good

(b) Bad

7.45 Checking brush wear of starter

Tools required

• V

ernier caliper

• Emery paper (#300 or above)

4. ENGINE

SERVICING

7. Servicing

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...