4. Checking and adjusting

4.1 Checking compression pressure

of cylinder

NOTE

• Check the

compression pressure with the

specified valve clearance.

• Always use a fully charged battery for you do

this test.

• Variances in cylinder compression values must

be less than 10%.

Tools required

• Compression tester

• Injector adapter

1. Warm-up the engine.

2. Remove the air cleaner and muf

fler.

3. Remove the glow lead and glow plugs.

4. Disconnect the injector connectors.

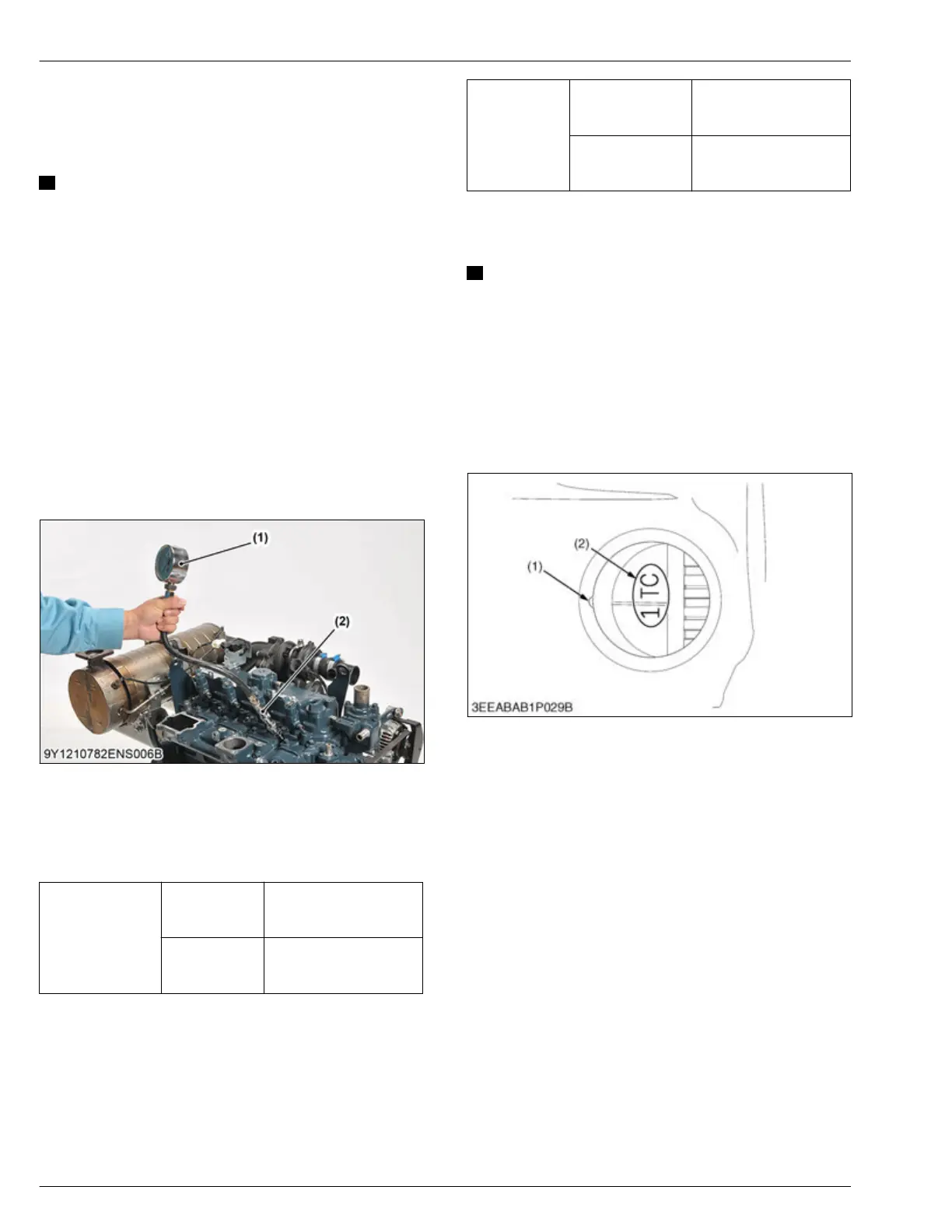

5. Set a compression tester (1) with the compression

tester adapter (2) to the glow plug hole.

(1) Compression tester (2) Compression tester adaptor

6. Crank

the engine with the starter to operate the

engine approx. 200 to 300 min

-1

(rpm).

7.

Measure a maximum value of the compression

pressure.

Compression pres-

sure

Service specifi-

cation

2.95 to 3.23 MPa

30.1 to 32.9 kgf/cm

2

428 to 468 psi

Service limit

2.35 MPa

24.0 kgf/cm

2

341 psi

8. Do the same steps twice for each cylinder.

9. Install the removed parts.

T

ightening tor-

que

Glow plug

14.7 to 19.6 N⋅m

1.50 to 1.99 kgf⋅m

10.9 to 14.4 lbf⋅ft

Glow lead mount-

ing nut

0.980 to 1.77 N⋅m

0.100 to 0.180 kgf⋅m

0.723 to 1.30 lbf⋅ft

4.2 Adjusting valve clearance

IMPORTANT

• You

must check and adjust the valve clearance

when the engine is cold.

Tools required

• Feeler gauge

1. Remove the air cleaner and muffler.

2. Remove the cylinder head cover

.

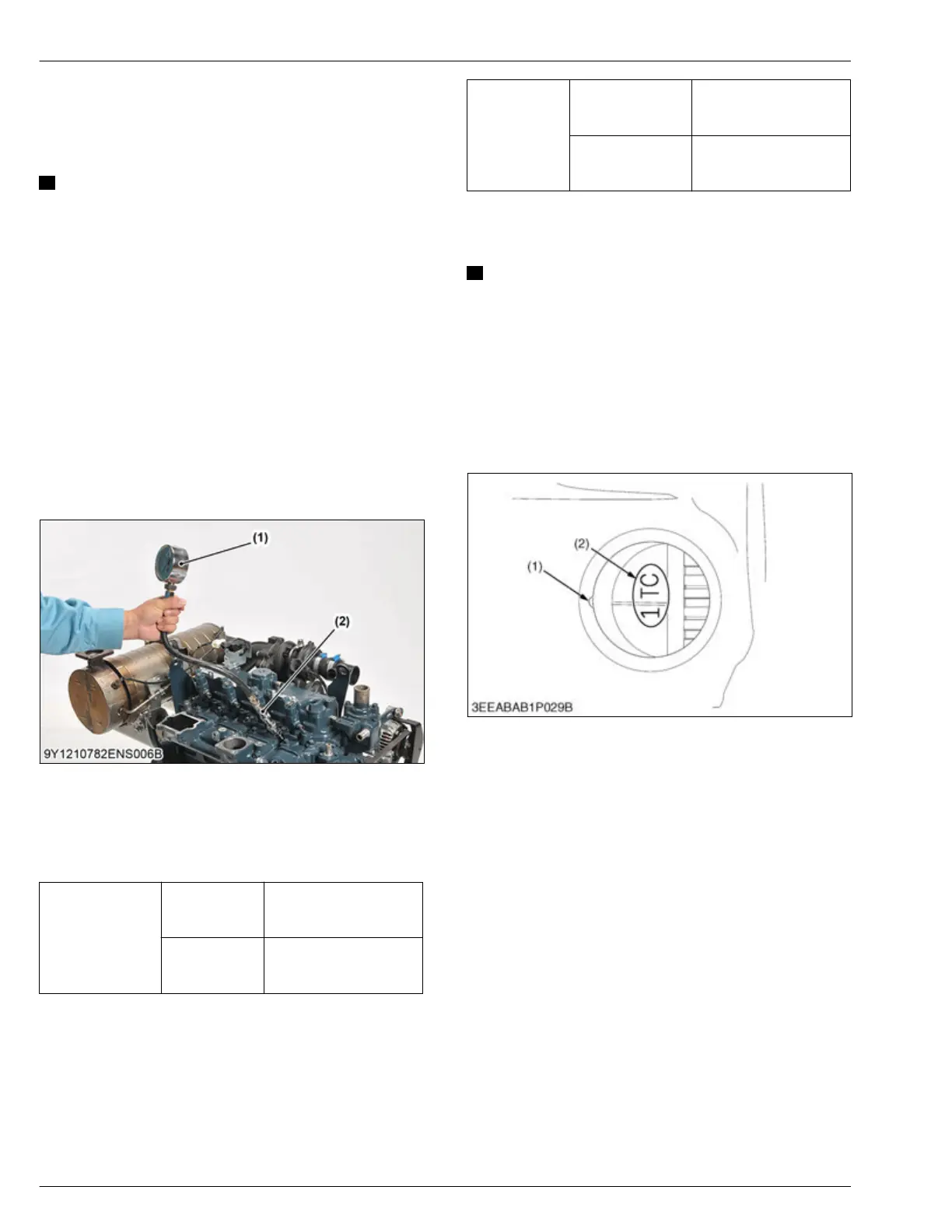

3. Align the [1TC] mark (2) line on the flywheel and

projection on the housing.

(1) Align mark (2) [1TC] mark

4. Make

sure that the No. 1 piston comes to the

compression or overlap top dead center

.

4. ENGINE

SERVICING

4. Checking and adjusting

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...