7. Install

the connecting rod cap (5) and loosely

tighten the connecting rod screw (4) by hand.

NOTE

• Apply engine

oil to the connecting rod

screws.

• If the connecting rod screw won't be

screwed in smoothly, clean the threads. If

the connecting rod screw is still hard to

screw in, replace it.

• When using the existing crankpin bearing

again, put tally marks on the crankpin

bearing and the connecting rod in order to

keep their positioning.

(4) Connecting rod screw (5) Connecting rod cap

8. Tighten the connecting rod screw (4) to the

specified torque.

T

ightening tor-

que

Connecting rod

screw (4)

40.0 to 45.0 N⋅m

4.08 to 4.58 kgf⋅m

29.5 to 33.1 lbf⋅ft

6.12 Installing oil strainer and oil pan

NOTE

• Clean the

oil pan and crankcase surface that

attached each other.

Tools required

• Liquid gasket (Three Bond 1217H)

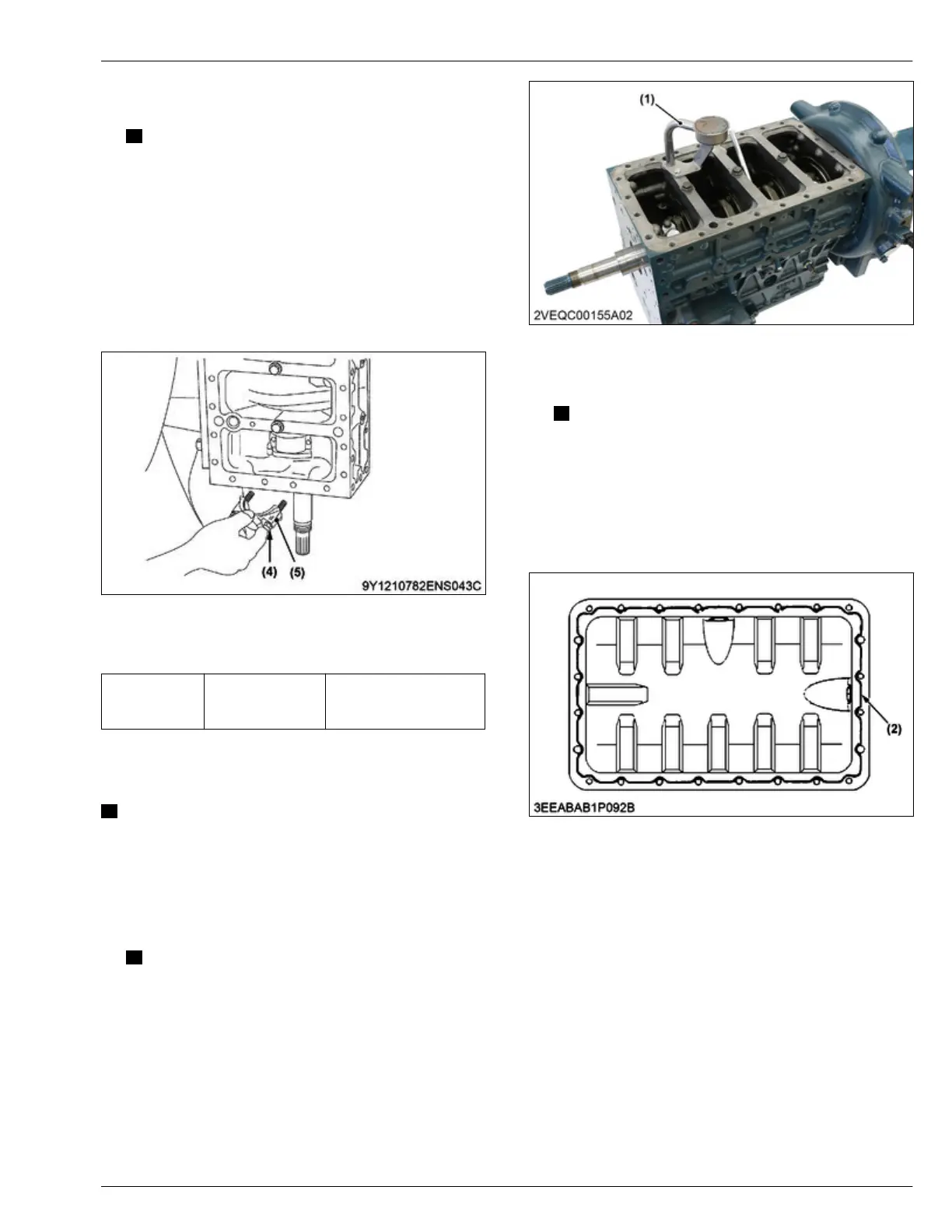

1. Install the oil strainer (1).

NOTE

•

Using care not to damage the O-ring.

•

After cleaning the oil strainer (1), install it.

(1) Oil strainer

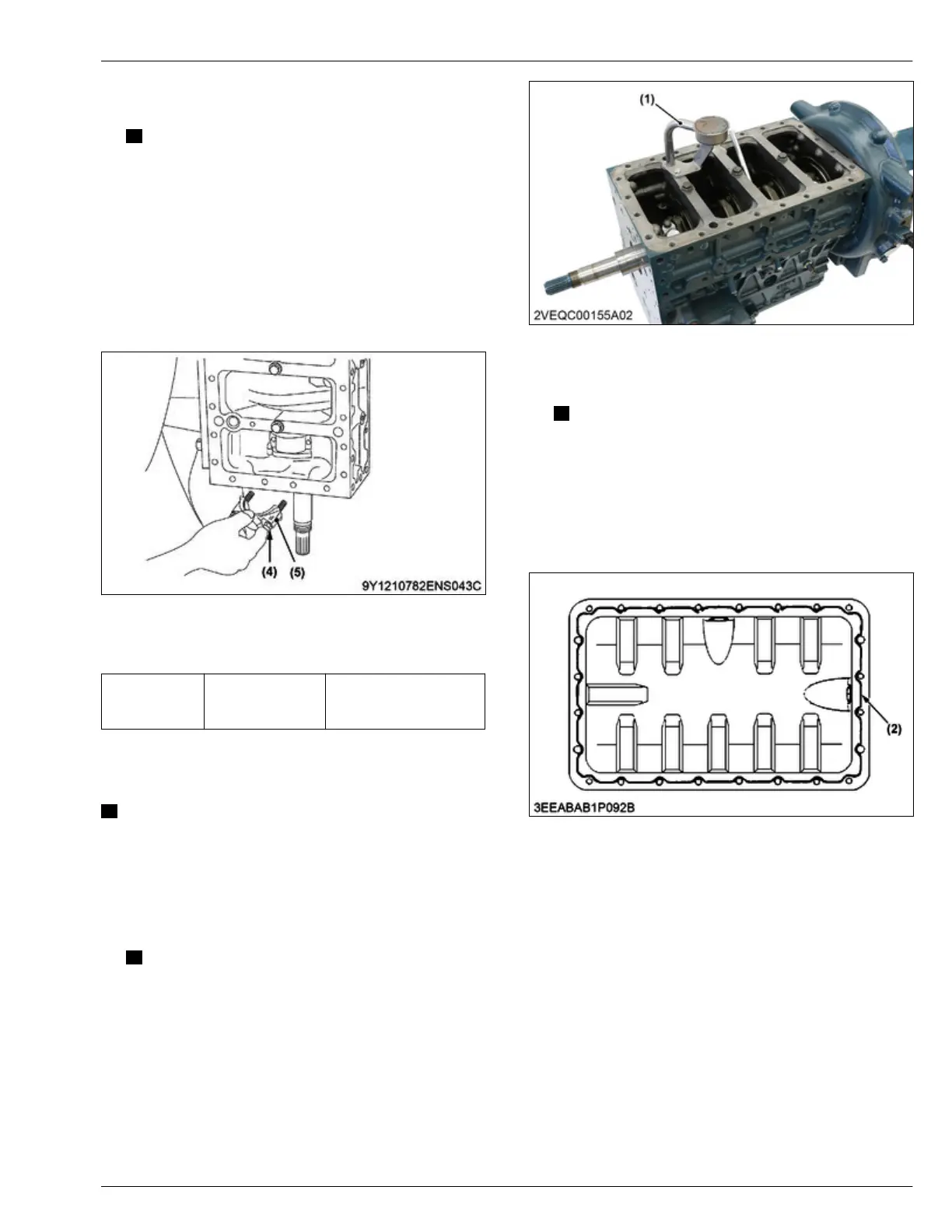

2. Apply liquid gasket (2) to the oil pan as shown in

the figure.

NOTE

• Confirm that

the liquid gasket (2) coating

surface is free of water, dust and oil in order

to keep sealing effect.

• Make sure the surfaces align when mounting

parts with a liquid gasket (2) applied to

them.

• Carefully apply the liquid gasket (2) evenly.

(2) Liquid gasket

SERVICING

6. Assembling 4. ENGINE

D1803-CR-E4,D1803-CR-TE4,D1803-CR-TIE4,V2403-CR-E4,V2403-CR-TE4,V2403-CR-TE4BG,V2403-CR-TIE4

Loading...

Loading...